Website:

Amann Girrbach

Website:

Amann Girrbach

Catalog excerpts

JWmmk GENERATION DENTISTRY UNIFIED Highly esthetic and precisely fitting restorations made of Zolid zirconia

Open the catalog to page 1

INTRODUCTION Zirconium oxide for great expectations 4 Processing techniques and indications 6 CAD/CAM DESIGN CAD/CAM Design 9 Nesting of Multilayer blanks 11 Sintering support structures 13 REMOVE & REFINE - FINISHING ZIRCONIUM OXIDE Finishing 15 Finishing before sintering 16 Finishing after sintering 17 INTERNAL FINISH - HANDLING STAINING LIQUIDS Processing of liquids 19 Staining with gingiva section 23 SINTERING Sintering of Zolid restorations 25 EXTERNAL FINISH - INDIVIDUALIZATION AFTER SINTERING Final characterization after sintering 29 System solution Creation Magic Colour 30 TRAINING...

Open the catalog to page 2

Overview of the Zolid product range Zirconium oxide for great expectations ½z olid ht n-x CENCY – HIGH U +w ge STR NSL hi EN RA lid 50 MPa* / 1)1100 T ±1 t ±1 G zo H 000 Multi-un it, screw-reta ine restoration d s on titanium b ases tomical y ana Full and bridges wns cro it extending 3-un ed s, ax. in oral region) (m ta ase he m to t -re m b ys, a u ni onl nts , me ut Mu rest lti-u ni or Ven ation t, sc s Cus eers on rew tom , in tita ise lay s d ab clinically proven manufactured in-house ically reduced Anatom crowns and 3-unit to multi-unit frameworks bridge Zirconium oxide enjoys great...

Open the catalog to page 4

Optimized workflows for maximum patient satisfaction As esthetics are not happenstance Amann Girrbach's Esthetic Management comprises products and solutions required for all work steps from milling and sintering of a restoration through to the final result. Here, the focus is on the most efficient, simple and reproducible workflows for the user – for highly esthetic results and high patient satisfaction. The clearly illustrated processing technique as well as numerous video tutorials guide users through the process step by step. In addition, users have a wide range of courses and online...

Open the catalog to page 5

Adjustment of existing parameters Processing techniques and indications The optimum zirconium oxide for an indication is determined by a host of different factors. Esthetic requirements, the position of the denture in the patient's mouth or the shade of the stump have a decisive influence on the choice of material. The more precisely the shade of the stump, the material and the indication are matched, the more predictable and esthetically accurate the final result will be realized. — LT / ZI — HT+ / Zolid Gen-X, Zolid HT+ White, Zolid HT+ PS, Zolid DRS — SHT/HT+ / Zolid Bion — SHT / Zolid...

Open the catalog to page 6

Zolid Bion / Amann Girrbach

Open the catalog to page 7

CAD/CAM DESIGN

Open the catalog to page 8

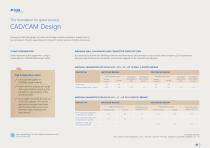

The foundation for good success CAD/CAM Design During the CAD/CAM design of crowns and bridges certain parameters already have to be considered. Only this guarantees the long-term clinical success of Zolid restorations. STUMP PREPARATIONS Some important points apply when using a model (plaster, CAD/CAM fabricated model). MINIMUM WALL THICKNESSES AND CONNECTOR CROSS-SECTION It is essential to observe the following minimum wall thicknesses and connector cross-sections when designing Zolid restorations. Minimum wall thickness and connector cross-section depend on the material and indication....

Open the catalog to page 9

Clean data sets lead to success Design of the restorations In addition to minimum wall thickness and connector cross section, which must be strictly complied with during the fabrication of Zolid restorations, it is essential to also observe other points: TIPS FOR A “CLEAN” DATA SET Supportive design in the area of the cusps and the proximal contact for the subsequent veneering ceramic. Change display to “wireframe” Display of an optimal connector cross-section To give precise milling results, “clean” STL data sets should be generated and transferred to the CAM software. Once the final...

Open the catalog to page 10

Maintaining proportions Nesting of Multilayer blanks Depending on the nesting position, a total of two tooth shades per blank can be covered with the Zolid FX Multilayer blanks. A few aspects need to be taken into account to ensure that the shade gradient is optimally matched. The choice of the correct blank height in proportion to the restoration height is decisive for success. Perfect for restorations with the following heights: approx. 6-8 mm The following applies in general to the nesting of Zolid Bion, Zolid Gen-X and Zolid FX Multilayer blanks: under no circumstances should too low...

Open the catalog to page 11

Zolid zirconia ready to meet different requirements Magnification factor To compensate for volume shrinkage during the sintering process, restorations made of Zolid zirconia and Ceramill Sintron are always fabricated with a certain allowance. This is defined by entering the so-called magnification factor in the CAM software. There are various CAM software systems on the market, all of which require different values to be entered. To meet the various requirements, the Zolid zirconia blanks are marked with the following three specifications for the magnification factor: Note: the...

Open the catalog to page 12

Sintering support structures To avoid problems of distortion and fit, large span bridges should always be sintered with a supporting structure. The following bridge constructions require a sintering support structure under all circumstances: - Bridge constructions with more than 9 pontics - Bridge constructions with a pronounced curvature, such as anterior tooth bridges Selection of a suitable sintering block The connectors should be arranged as symmetrically as possible Tips & important notes ö For the support structure, the “dynamic stabilizer” is selected in the CAM software ö The...

Open the catalog to page 13

REMOVE & REFINE

Open the catalog to page 14

Product recommendations for the perfect finish To prevent damage to the material, correct finishing is essential after the milling process. Here a distinction is made between finishing before sintering and finishing after sintering. The choice of suitable instruments is crucial for success. Green-State Finishing Kit for finishing zirconia restorations before sintering. Polishing paste for final high gloss polishing Sinter-State Polishing Kit for finishing zirconia restorations after sintering.

Open the catalog to page 15All Amann Girrbach catalogs and technical brochures

-

Clinical Guide III

28 Pages

-

Zolid Bion

8 Pages

-

Ceramill Workflow

60 Pages

-

Ceramill DRS

40 Pages

-

Newsflyer 2023

32 Pages

-

AG General Catalogue

111 Pages