Website:

Genstar Technologies Company

Website:

Genstar Technologies Company

Catalog excerpts

Company Overview Founded in 1969, Genstar Technologies Co., Inc. (Gentec) is a world-class manufacturer specializing in producing high quality gas control components. Gentec's product lines include ultra high purity, high purity, and industrial gas control and handling devices, medical gas control systems, high pressure gas products, and gas welding apparatus. As a total system solution provider, Gentec also offers its customer value-added services such as technical support, on-site evaluation, design and implementation. With its ISO 9001 certified 150,000 square foot manufacturing...

Open the catalog to page 2

With a wide variety of connection sizes and styles, materials of construction, temperature capabilities, and pressure ranges, GENTEC Valves provide the user with great flexibility when designing tubing or piping systems. To ensure product quality and performance, Gentec valves are manufactured using exquisite craftsmanship in conjunction with computerized automations, stringent quality control, and advanced test equipment. With superior designs, Gentec valves also provide leak tight performances and long cycle lives.

Open the catalog to page 3

1 Pressure rating: 5000 psig (345 bar) 1 Suitable for corrosive services, high pressure sampling systems, and shut-down systems. 1 V pattern is the standard stem style. R pattern and K pattern are also 1 End connections include GENLOK and NPT types. 1 Tube fitting connections in sizes: 1/8", 1/4", 3/8", 1/2" and 3/4". 1 Straight pattern is the standard body style. Angle pattern is also 1 Knob handle is the standard handle style. Bar pattern is also available. 1 Allow for panel mounting. 1 For oxygen service, please select oxygen cleaning option. 1 Every valve is factory tested at 1000 psig...

Open the catalog to page 4

AddSS for 316 stainless steel as a prefix to the Basic Ordering Number. Angle Pattern Add A as a suffix to the Basic Ordering Number. Example: SS-NVH-TFI2-A Add Has a suffix to the Basic Ordering Number for Regulating stem; Vfor Vee stem; orK for Soft-seat stem. Example: SS-NVH-TFI2-V Oxygen Cleaning Add Das a suffix to the Basic Ordering Number. Example: SS-NVH-TFI2-D Add B as a suffix to the Basic Ordering Number. Example: SS-NV14-TF12-B Straight Pattern Angle Pattern Connection Sizes Panel Mounting Drill Dia.(mm)

Open the catalog to page 5

■ Pressure rating: 3000 psig (207 bar)- BV15 1 Directional handle indicating on-off positions. 1 Single-piece ball stem to eliminate backlash. 1 One-piece body to eliminate multiple-seal points. 1 Unique top-loaded capsule packing allows reliable switching. 1 End connections include GENL0K, NPT and FSR types. 1 Straight pattern is the standard body style. Angle pattern is also 1 Allow for panel mounting. 1 For oxygen service, please select oxygen cleaning option. 1 Every valve is factory tested at 1000 psig (29 bar) for leakage. Adjust packing nut when working pressure is higher than 1000...

Open the catalog to page 6

AddSS for 316 stainless steel as a prefix to the Basic Ordering Number. Example: SS-BVW-TFB Angle Pattern Add A as a suffix to the Basic Ordering Number. Example: SS-BVW-TFB-A Oxygen Cleaning Add Das a suffix to the Basic Ordering Number. Example: SS-BVW-TFB-D Straight Pattern Angle Pattern * FSR = Face Seal Fitting

Open the catalog to page 7

GENTEC Check Valves are designed for single directional gas flow control in applications such as chemical processing, pharmaceutical, 1. Cracking pressures: 1,3,10 & 25 psig 2. Connections: NPTand GENLOKtypes 3. Back stopper poppet to minimize stress of spring. 4. Tested 100% for cracking & reseal pressure. Seal Materials Viton® 0-rings are standard in 316 stainless steel valves. Other 0-ring materials are available. Cracking and Reseal Pressures at70°F( 20°C}

Open the catalog to page 8

AddSS for 316 stainless steel as a prefix to the Basic Ordering Number. Example: SS-CVW-TFW Please add the Seal Material and Cracking Pressure respectively to the Basic Ordering Number. Example: SS-CVW-TFW-Vl-l

Open the catalog to page 9

Ordering Information Needle Valves Series Number Inlet Connection* Outlet Connection* V: Vee stem K: Soft-seat stem R: Regulating stem Ball Valves Series Number Outlet Connection*

Open the catalog to page 10

Check Valves Series Number CV1: Check Valve Inlet Connection* Outlet Connection* Seal Materials VI: Viton® BU: Buna N EP: Ethylene propylene NE: Neoprene KZ: Kalrez® TR: PTFE 1 psig 3 psig 10 psig 25 psig *: Please look below for details. Inlet & Outlet Connections Designator TF: Tube Fitting NT: Male NPT FNT: Female NPT FSR: Face Seal Fitting Viton® , Kalrez® are registered trademarks of DuPont Corp.

Open the catalog to page 11

Genstar Technologies Company, Inc. 4525 Edison Avenue Chino, CA 91710, USA Tel: 909-606-2726 Fax: 909-606-6485 www.genstartech.com GLOBAL TECHNICAL SUPPORT & DISTRIBUTION DESIGN & MANUFACTURING FACILITIES IN THE UNITED STATES & CHINA NOTE: PRODUCT AVAILABILITY AND SPECIFICATIONS CONTAINED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTICE. CONSULT LOCAL DISTRIBUTOR OR FACTORY FOR POTENTIAL REVISIONS. COPYRIGHT © 2004 GENSTAR TECHNOLOGIES CO., INC.

Open the catalog to page 12All Genstar Technologies Company catalogs and technical brochures

-

CRYOGENIC GAS EQUIPMENT

18 Pages

-

Oxygen & Suction Therapy

68 Pages

-

MEDICAL HEADWALL UNITS

2 Pages

-

FM293 SERIES

1 Pages

-

Oxygen & Air Flowmeters

2 Pages

-

OxyBlend Air/Oxygen Blender

4 Pages

-

880VS SERIES

2 Pages

-

Vacuum Regulator Flush

1 Pages

-

Suction Regulator parts

1 Pages

-

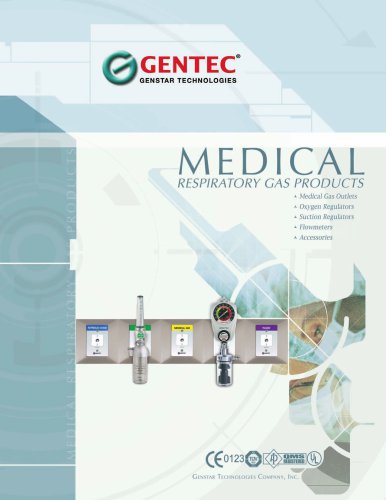

Medical_Respiratory_Catalog

36 Pages

-

DIGITAL SUCTION REGULATOR

2 Pages

-

Area Valve Service Unit

2 Pages

-

Medical Gas Control Panel

2 Pages

-

Ball Valves with Extensions

2 Pages

-

co2 beverage regulator

4 Pages

-

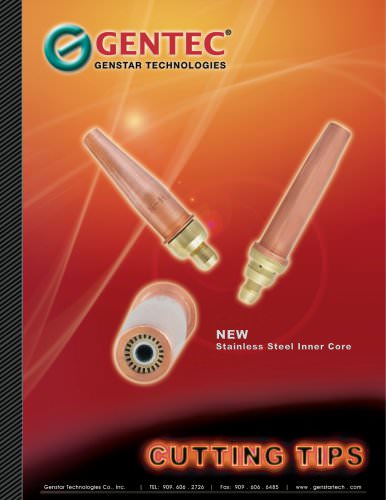

Cutting Tips

4 Pages

-

Alternative Fuel Solutions

4 Pages

-

Gold Series

3 Pages

-

Accessories Catalog

16 Pages

-

Silver Series

2 Pages

-

Gas Control Overview

5 Pages

-

Cryogenic

8 Pages

-

Filters

6 Pages

-

Tube Fittings

32 Pages

-

Gas Safety Cabinets

2 Pages

-

Cylinder Connections

15 Pages

-

Industrial Gas Manifolds

40 Pages

-

Specialty Gas Equipment

140 Pages

-

Ultra High Purity Catalog

52 Pages

-

Medical Gas Outlets

2 Pages

-

Medical Bedhead Units

2 Pages