Website:

MCQ Instruments

Website:

MCQ Instruments

Catalog excerpts

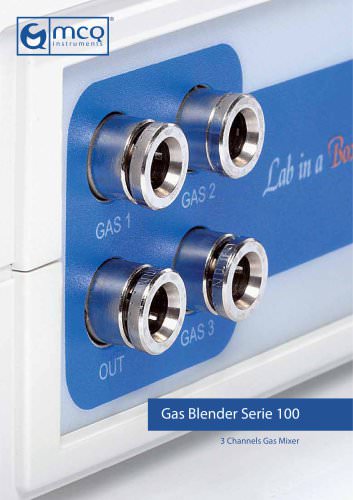

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Application Note MCQ Gas Blender 100 Series Application Gas Sensors: calibration, testing and development Introduction Monitoring ambient conditions is a fundamental feature providing valuable data for both research and production applications. Any basic or advanced experimentation, any standard or crucial step in a production process demands a fine control over working conditions, thus implying the need of a proper monitoring apparatus. Along with temperature and pressure, the ability to check the atmosphere composition becomes relevant since the presence, absence or simply the amount modification of the gas species can strongly affect the final result. For that reason gas sensors are today a part of the essential equipment of many research labs and production facilities, as well as common safety devices for residential buildings. Measurement devices like gas sensors require regular maintenance to check and secure proper functioning. Standard procedures usually involve testing and re-calibration of the sensors, for which working atmospheres with specific composition are needed. Creation, control and management of custom gas mixtures can be easily achieved with the new MCQ professional instrument: the Gas Blender 100 Series. The Gas Blender 100 Series is also an incredible versatile tool for the creation of brand-new gas sensors. The instrument is the optimal choice for developing gas sensors dedicated to applications with specific ambient measurement requirements, for which standard sensors commercially available are not suitable. Gas Sensors There are many types of gas sensor commercially available, built for different purposes and designed for specific applications. Gas sensors can be divided in two main families, electrochemical or spectroscopic, accordingly with their working principle. www.mcqinst.com Gas Blender 100 Series Application Note

Open the catalog to page 1

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Calibration The calibration of the majority of commercial gas sensors can be executed by the product supplier or by the user. A calibration performed by the supplier requires a standard fee, to which the shipping cost of the sensor must be added. If the sensor can not be shipped, or requires a specific calibration in situ, an operator actually performing the calibration is required and the related cost must be taken into account. A calibration executed by the user does not involve any fee but requires the...

Open the catalog to page 2

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Accurate calibrations require more than 1 point for the span regulation, thus an expansive set of gas cans, each containing a different atmosphere, is needed. Calibration of custom gas sensors may require specific atmospheres not commercially available. standard calibration. This method however suffers two major downsides: Short distance points MCQ has developed a new product to overcome these problems: the Gas Blender 100 Series. This product has been specifically designed for applications requiring custom gas...

Open the catalog to page 3

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface In order to check and verify them, the use of sensors with adequate sensibility and fast RT is mandatory. Experimental scenario: The working system is surrounded by a specific atmosphere, constantly monitored with one or more gas sensors. The system, naturally or artificially, incurs in a short-time event that alters the mixture composition for 400 ms. Lost data After 400 ms, the system’s conditions are fully restored to thier starting values. In order to measure the variation within the system, the sensors’...

Open the catalog to page 4

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface manageable product, ideal for installation in narrow spaces or under chemical hoods. User Interface All the Gas Blender parameters and functions can be easily controlled by the user with the MCQ Gas Mixer Manager, provided with the instrument. The software is a fast and intuitive tool for the Gas Blender management and configuration, which only requires a desktop or laptop computer with any Windows operating system starting from Windows XP. Hardware configuration The image alongside represents an example of...

Open the catalog to page 5All MCQ Instruments catalogs and technical brochures

-

GB NANO 3

4 Pages

-

GB 15k

2 Pages

-

GB 2000

4 Pages

-

GB 3000

4 Pages

-

GB 3000

4 Pages

-

GB 4000

4 Pages

-

GB 6000

4 Pages

-

GB 100

4 Pages

-

GB 100 plus

4 Pages

-

SensorModule

7 Pages

-

Sensor Module

7 Pages

-

Gas Blender Advantages

4 Pages

Archived catalogs

-

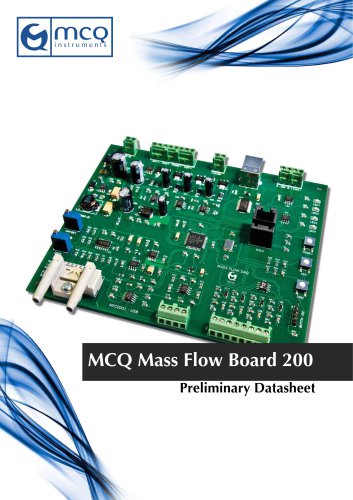

Flow Board

11 Pages

-

Gas Blender 106 Series

4 Pages

-

Data acquisition board

4 Pages