Website:

Addfield Environmental Systems

Website:

Addfield Environmental Systems

Catalog excerpts

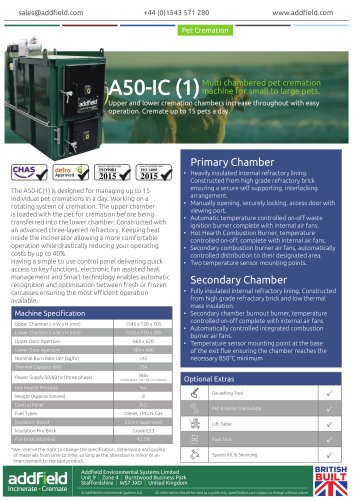

Large Capacity Bulk Pet Cremation Machine. An oversized pet cremation machine designed for high throughput bulk cremation operation. QUALITY ASSURED FIRM A highly optimised solution for securely managing bulk pet cremations enabling the processing of several simultaneous pet cremations in a day. Regularly installed in growing and established pet crematorium due to its compact and efficient operation. Also trusted by research centres, kennels, and animal rescue facilities. Equipped with the necessary sophistication of control and designed to cremate pets and mixed animal carcasses in a safe, clean and environmentally friendly manner. Machine Specification External L x W x H (mm) Weight (approx tonnes) Nominal Burn Rate UK* (kg/hr) Burn Rate [Export Only]* (kg/hr) Primary Chamber Primary Chamber QUALITY ASSURED FIRM • Heavily insulated internal refractory lining. • Fully insulated internal refractory lining, constructed • Constructed frominternal refractory lining. Heavily insulated high grade refractory brick ensuring a secure self-supporting, interlocking from high grade refractory brick ensuring abrick Constructed from high grade refractory selfarrangement. supporting,secure self supporting, interlocking ensuring a interlocking arrangement. • Fully interlocked, manually operated, access door. with Manually opening, securely locking, access door arrangement. • Waste ignition burner, temperature controlled on-off, • viewing port. Manually opening, securely locking, access door with Automatic temperature fans. • complete with internal aircontrolled on-off waste viewing port. • Combustion burner, temperature controlled fans. ignition burner complete with internal air on-off, • complete with internal aircontrolled on-off waste Automatic temperature • Temperature controlled, fans. internal air fans. ignition burner completeon-off combustion burners, • Secondary with internal airwith fans with automatically complete combustion burner air temperature fans. • controlled distribution to their designated area. Hot Hearth Combustion Burner, One temperature sensor mounting point. • controlled on-off, complete with internal air fans. • Two temperature sensor mounting points. • Secondary combustion burner air fans, automatically controlled distribution to their designated area. • Fully temperature sensor mounting points.from a Fully insulated internal lining, constructed • Two insulated internal refractory lining, constructed from high high grade and robust fibre or concrete. choice of grade refractory brick and low thermal mass • insulation. chamber burnout burner, temperature Secondary • Secondary chamber burnout burner,lining. Constructed • Fully insulated internal refractoryinternal air fans. controlled on-off, complete with temperature from high grade complete brick andcombustion • controlled on-off, refractorywith internal airthermal Automatically controlled integrated low fans. mass insulation. • Integrated fans. burner air combustion burner air fans with • automatically controlled distribution totemperature • Secondary chamber burnout burner, at thedesignated Temperature sensor mounting point their base area. exit flue ensuring thewith internal air fans controlled on-off complete chamber reaches the of the • All combustion controlled integrated combustion Automatically fuel pipework. necessary 850°C minimum, with a 2 second retention • All electrical components. burner time. air fans. • One temperature sensor mounting point at the base • Temperature sensor mounting air fans, automatically • of the exit flue ensuring the chamber reaches base Secondary combustion burner point at the the of the exit flue ensuring the chamber reaches the controlled distribution to their designated area. necessary 1100°C minimum. necessary 1100°C minimum Secondary Chamber Secondary Chamber Thermal Capacity (kW) Power Supply 50/60 hz Optional Extras Door Aperture Fuel Types Control Panel Insulation Fire Brick Insulation Board Fire Brick (Alumina) De-ashing Tool Fuel Tank Lift Table *We reserve the right to change the specification, dimensions and quality of materials from time to time, so long as the alteration is minor or an improvement to the said product. Addfield Environmental Systems Limited Unit 9 | Zone 4 | Burntwood Business Park Staffordshire | WS7 3XD | United Kingdom © Addfield Environmental Systems Ltd. All information should be used as a guide onl

Open the catalog to page 1

A PAI Large Capacity Bulk Pet Cremation Machine. Waste Loading and De-Ashing The A50L cremator has been designed to allow for easy and safe loading of multiple pets for each cremation cycle. A wide front opening door provides access to the primary chamber for loading to be completed manually or with the aid of a hydraulic lifting table. This system can be safely loaded multiple times throughout a cycle to ensure maximum output can be achieved. At the end of every cremation process ash should be removed prior to the next burn. The Addfield Difference • Pre-Fabricated 8mm & 10mm robust mild...

Open the catalog to page 2

CHECKED APPROVED CHECKED APPROVED CHECKED APPROVED CHECKED APPROVED COMMENTS CHECKED APPROVED This drawing and any information or descriptive material set out on it are the confidential and copyright propertyof Addfield Enviromental Systems, and MUST NOT BE DISCLOSED, COPIED, LOANED in whole or part or used for any purpose without the written permission of Addfield Enviromental Systems. Addfield Environmental Systems LTD Addfield Environmental Systems LTD Unit 9, Zone 4 Burntwood Business Park Staffordshire WS7 3XD A50L Sale GA SHEET 1 OF 1 SCALE: 1:60 2 THIRD ANGLE PROJECTION (UNLESS...

Open the catalog to page 3All Addfield Environmental Systems catalogs and technical brochures

-

MINI AB

3 Pages

-

A50-IC (1)

3 Pages

-

Pet Cremation

6 Pages

-

TB

3 Pages

Archived catalogs

-

Lambing Season

1 Pages

-

Keeping Saudi Arabia safe

1 Pages

-

Invaded by Japanese Knotweed

1 Pages

-

Containerised Pet Crematoria

1 Pages

-

Treasured Friends Case Study

1 Pages

-

INDIVIDUAL CREMATOR

5 Pages

-

Large Incineration Solutions

8 Pages

-

N20-AA

5 Pages

-

N20

5 Pages

-

PHOENIX 3

5 Pages

-

PHOENIX 2

5 Pages

-

PHOENIX 1

5 Pages

-

N20-SA

5 Pages