Website:

Addfield Environmental Systems

Website:

Addfield Environmental Systems

Catalog excerpts

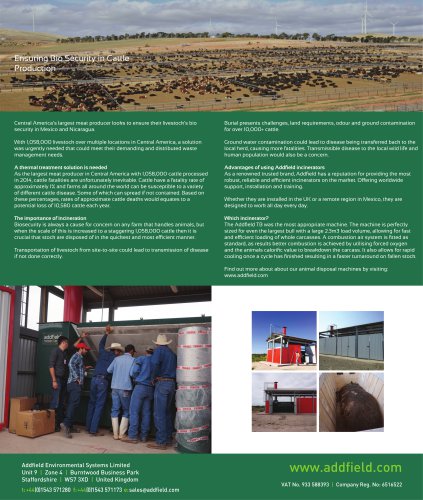

The Middle East’s Largest Poultry Producer Chooses Addfield Addfield continues to build it’s reputation as the most trusted supplier of International Poultry Incineration with the installation of three of their Rapid 000 Incinerators. Working with one of the largest poultry facilities in the Middle East. We have recently supplied one of the Middle East’s largest poultry producers with three Rapid 1000 poultry incinerators. The company supplied, currently achieves a daily production of close to half a million birds and one million eggs. The company has a strong commitment to the environmental impact of its operation and are committed to quality and as such have become one of the first Poultry Companies in the Middle East to achieve ISO certificate 9002 (currently ISO 9001-2000) they have also achieved HACCP and SQF 200 Certification. So what went wrong? Having previously purchased and installed poultry incineration machines from a number of different European and UK manufacturers. However these machines were consistently failing to meet the exacting demands of such a large operation rapidly developing consistent failures time and time again, these included: The equipment that had been supplied previously was not fit-for-purpose. They had been supplied with generic machines that were sold with little consideration to the low calorific value of the waste type – poultry carcasses and the additional demands that this would put on an incinerator. Low quality, poor grade, refractory concretes which cracked within months of installation The machines where being purchased based on price, yet little consideration was being made for their longevity. Existing equipment was lasting 6-12months before being replaced – when the reality should have been 15 years for a quality incinerator. Incomplete combustion of Poultry waste. Pressurising units and undersized pollution control systems Environmental concerns regarding the excess emission of smoke. How did things change? Addfield, the experts came along. Our reputation has been built upon the quality of our equipment, for example, a number of our incinerator plants are still fully functioning today, some 23 years after installation. The reasons that our equipment was the right solution for include: 1. We only use high-quality UK sourced, refractory material. Specialising in multi-layer brick refractories. The same that you might find in any petrochemical site or PowerStation. 2. We designed a unit to specifically deal with the high volume of waste generated and the specific needs of the waste being of low calorific content. 3. Units were fully CFD (Computational Fluid Dynamics) modeled and tested beforehand, to eliminate hot and cold spots to ensure a free flow of gasses. Secondary chamber sizes were also verified to ensure correct sizing eliminating incomplete oxidisation in the secondary chamber. 4. Units were fully inspected by the Saudi Arabian Government Environmental Inspectors (PME) “The most advanced batch loading agricultural incinerator anywhere in the world” The Rapid 1000 was designed for processing a very high output and selected to ensure that the machine would be fit for purpose for years of constant use without requiring costly repairs or suffer critical failures, which had occurred when they had purchased competitors’ products. The Rapid 1000 was selected for this project for the following reasons: 1. Castellated hearth bar™ the support superstructure doubles the flame penetration to the waste. Currently, there is no other system that compares to this for results. 2. Capable of incinerating up to 1000kg/hr consistently to ensure smooth operation and reduce bottle necks within the business. 3. The thorough incineration process produces clean sterile ash, suitable for easy disposal with minimal risk of contamination. 4. High-quality white, sterile ash content. 5. Having a multi layered brick lined refractory ensures maximum fuel efficiency keeping the heat exactly where it is needed and reducing operational cost. 6. All Addfield machines are constructed from a robust 10mm thick steel creating a product that is built to last for years. 7. Hydraulic opening lid for speedy and safe operation. With soft opening and closing to protect the machine and user. 8. Air conditioned control panels to withstand the environmental conditions of a desert environment, 9. Touch screen smart interface with data output delivering a highly accurate incineration process with opportunity to review processes, data-logging and customise for optimum efficiency Addfield Environmental Systems Limited Unit 9 | Zone 4 | Burntwood Business Park Staffordshire | WS7 3XD | United Kingdom t: +44(0)1543 571280 f: +44(0)1543 571173 e: sales@addfield.com

Open the catalog to page 1All Addfield Environmental Systems catalogs and technical brochures

-

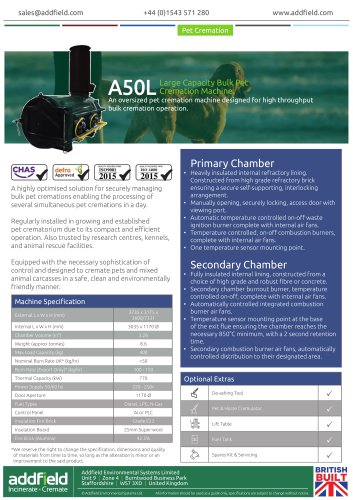

A50L

3 Pages

-

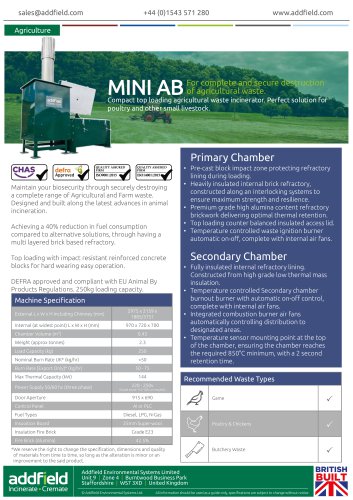

MINI AB

3 Pages

-

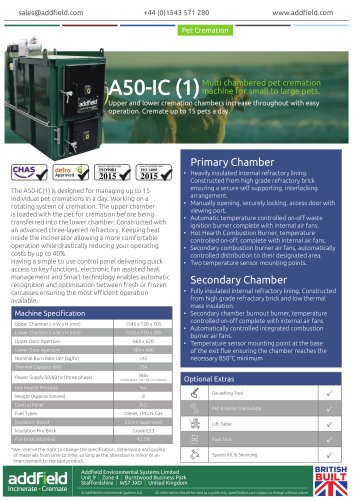

A50-IC (1)

3 Pages

-

Pet Cremation

6 Pages

-

TB

3 Pages

Archived catalogs

-

Lambing Season

1 Pages

-

Keeping Saudi Arabia safe

1 Pages

-

Invaded by Japanese Knotweed

1 Pages

-

Containerised Pet Crematoria

1 Pages

-

Treasured Friends Case Study

1 Pages

-

INDIVIDUAL CREMATOR

5 Pages

-

Large Incineration Solutions

8 Pages

-

N20-AA

5 Pages

-

N20

5 Pages

-

PHOENIX 3

5 Pages

-

PHOENIX 2

5 Pages

-

PHOENIX 1

5 Pages

-

N20-SA

5 Pages