Website:

Addfield Environmental Systems

Website:

Addfield Environmental Systems

Catalog excerpts

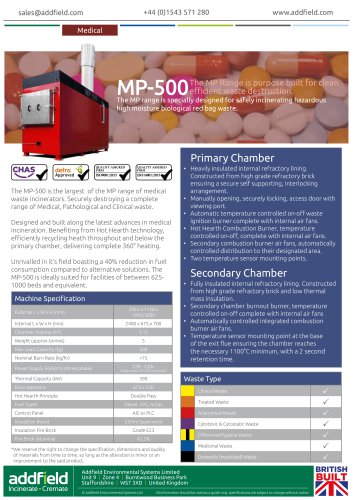

Pharmaceutical Waste Management in Algeria Addfield TBABMAX Client Overview Stidest specialises in the collection, treatment and incineration of waste. Their main groups are pharmaceutical, veterinary, medical and paramedical. This usually consists of expired drugs, waste with a risk of infection and general medical waste you would expect to find at a hospital. Stidest’s main asset was their incinerators, but the ones that they had from an Addfield competitor were not fit for purpose. So much so, that they were later taken off the company’s website and they ceased to sell the machine. An incinerator is needed As Algeria’s leading waste management company, they needed machines that were able to cope with the large capacity of waste that would be incinerated each day which averages to 500 yellow bags (clinical waste) and 200 red bags (biomedical waste). Addfield suggested our second largest machine, the TB-AB-MAX for the general medical waste and the MP-500 for high moisture biomedical waste. Advantages of using Addfield Incinerators Incineration is a vital way of disposing medical waste due to the following: Addfield provided a range of scrubbers which are used with the machine to further reduce emissions from the incinerator; making it exceptionally environmentally friendly. Infection can easily be spread between animal and humans if the waste is not disposed of appropriately. Medical waste can be highly toxic so contact with it should be as limited as possible. Injuries often occur in countries where it is the norm to forage through waste for potential valuables Medical waste often contains chemicals that can be harmful to the environment when accumulated. Unrivalled experience that has been nurtured through hands-on experience such as commissioning machines on site All Addfield ranges are specifically designed for their intended use to ensure that the highest efficiency is gained for the waste type. Which incinerator The TB-AB-MAX has a huge capacity of 4000kg and an equally remarkable burn rate of 250kg to 500kg per hour depends on the calorific nature of the waste. This is controlled by our unique air control system and an intelligent PLC controller that can independently modulate individual burners ensuring a stable and controlled burn process. The MP-500 is specifically designed for high moisture and/or low calorific waste such as human organs, blood and swabs – a traditionally a hard-to-burn waste group. Hot hearth technology utilises twin burner system for the complete oxidation of waste. It operates by a hearth (or under floor) burner superheating the silicon carbide tiles on which the waste sites. Feedback Stidest was so impressed with the designated engineers work, the manager wrote him a letter to ‘express his sincere gratitude and congratulations’ as he ‘appreciated the diligence and dedication with which the engineer have conducted’ and he had ‘shown in addition to your skills, excellent responsiveness by adapting very quickly to what was asked’. Finally, he stated he could ’call on his cooperation in confidence, with the assurance of quality work, respecting deadlines’ which is exactly what Addfield aims to achieve. Addfield Environmental Systems Limited Unit 9 | Zone 4 | Burntwood Business Park Staffordshire | WS7 3XD | United Kingdom t: +44(0)1543 571280 f: +44(0)1543 571173 e: sales@addfield.com

Open the catalog to page 1All Addfield Environmental Systems catalogs and technical brochures

-

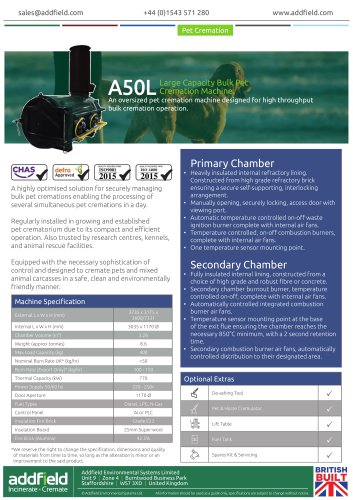

A50L

3 Pages

-

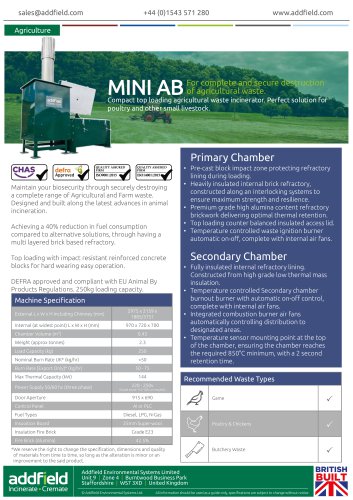

MINI AB

3 Pages

-

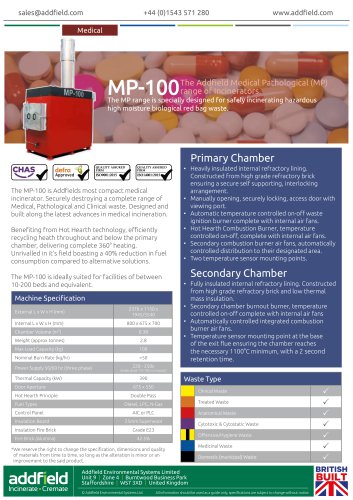

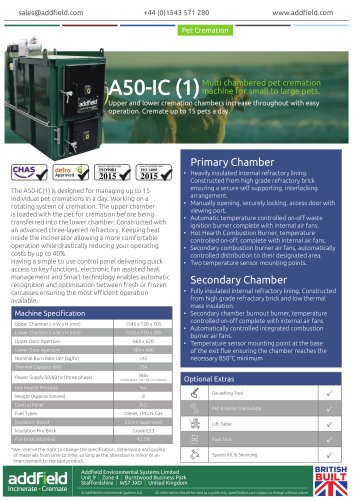

A50-IC (1)

3 Pages

-

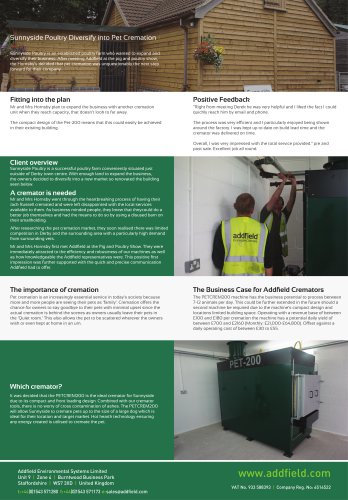

Pet Cremation

6 Pages

-

TB

3 Pages

Archived catalogs

-

Lambing Season

1 Pages

-

Keeping Saudi Arabia safe

1 Pages

-

Invaded by Japanese Knotweed

1 Pages

-

Containerised Pet Crematoria

1 Pages

-

Treasured Friends Case Study

1 Pages

-

INDIVIDUAL CREMATOR

5 Pages

-

Large Incineration Solutions

8 Pages

-

N20-AA

5 Pages

-

N20

5 Pages

-

PHOENIX 3

5 Pages

-

PHOENIX 2

5 Pages

-

PHOENIX 1

5 Pages

-

N20-SA

5 Pages