Website:

Addfield Environmental Systems

Website:

Addfield Environmental Systems

Catalog excerpts

‘The most thermally efficient, robust and reliable human cremators on the market Simply Built Better!’ Human Cremator Suitable for 3500-4000 cremations a year The PHOENIX 3 is our top-of-the-range, high volume human cremation unit. It benefits from 115mm refractory wall thickness and temperature controlled burners that ensure it has the lowest fuel consumption possible. Complete with a curved hot hearth design that contains and destroys high moisture content material. A touch screen control interface is employed with a fully automatic control sequence that removes the possibility of human error. It utilises a front loading door design for ease use and a separate remains removal door located on the rear of the unit. The main chamber has a volume of 2.97m³ and a maximum weight capacity of 453kg. Control System Addfield Environmental Systems Limited Hollies Park | Cannock | Staffordshire | WS11 1DB www.addfield.co.uk | sales@addfield.co.uk | 01543 571280 All information should be used as a guide only, specifications are subject to change without notice.

Open the catalog to page 1

Human Cremator Suitable for 3500-4000 cremations a year The human cremation range is designed as a two stage cremation unit comprising of a primary loading chamber that incorporates a hot hearth construction for the total destruction of the solid/liquid wastes. The unit is further complemented by an integral after burner system; this afterburner draws the hot gases from the primary chamber under the hearth through an integral refractory brick system. This ensures maximum gas turbulence/mixing is achieved thus aiding clean combusted gases. All gases then reside inside the after burner...

Open the catalog to page 2

Human Cremator Suitable for 3500-4000 cremations a year General Construction • Pre-fabricated from robust mild steel box tubing, with a thickness of 3.5mm externally and 2.7mm internally. Suitably stiened and braced where necessary so as to be self-supporting throughout. • Paint finishing - The steel structures are completely painted using a high grade paint system. The standard colour of the series is grey for the stack, primary and secondary chambers. The front loading door comes in black. • The Primary and secondary chamber are lined with thickness of 115mm, refractory insulation that is...

Open the catalog to page 3

Waste Loading and De-Ashing The human cremation series are designed for front loading only through the main access door. The hydraulic door is push button operated, this feature enables the operator to open the door to the desired height from the control panel, an important safety feature for busy installations. It provides better fuel efficiency and longer refractory life. At the end of every incineration process it is recommended the ash should be removed prior to the next incineration cycle. A separate remains removal door is located on the rear of the unit. A stainless steel cooling pan...

Open the catalog to page 4

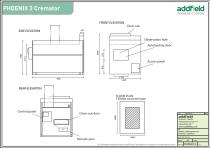

MP-100 INCINERATOR PHOENIX 3 Cremator FRONT ELEVATION SIDE ELEVATION Observation hole Autoloading door REAR ELEVATION FLOOR PLAN 150mm concrete base Clean-out door Control panel Incinerate - Cremate Addfield Environmental Systems Ltd Unit 17 Hollies Park Cannock Staffordshire WS11 1DP www.addfield.co.uk title GENERAL ARRANGEMENT OF PHOENIX 3 CREMATOR scale:- Not to scale drawn:- All information should be used as a guide only, specifications are subject to change without notice.

Open the catalog to page 5All Addfield Environmental Systems catalogs and technical brochures

-

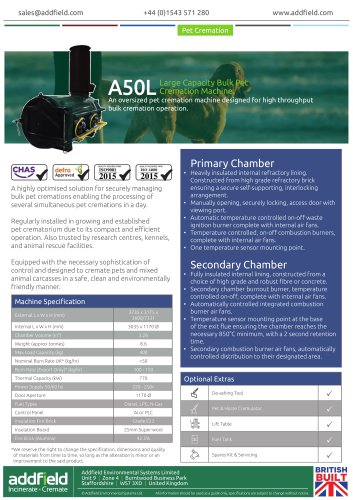

A50L

3 Pages

-

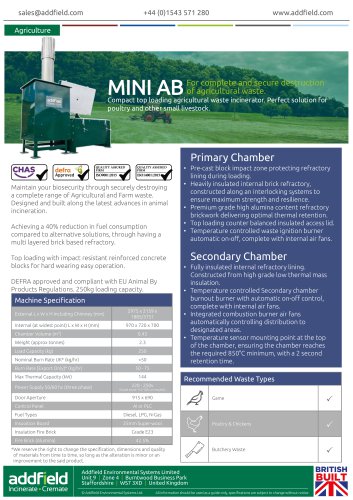

MINI AB

3 Pages

-

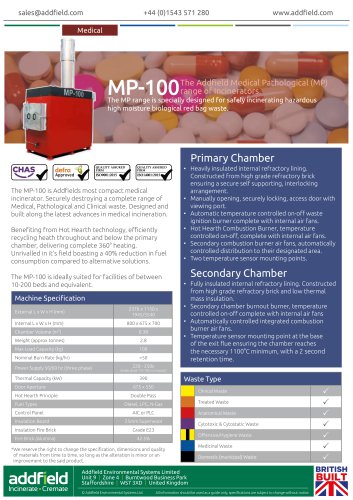

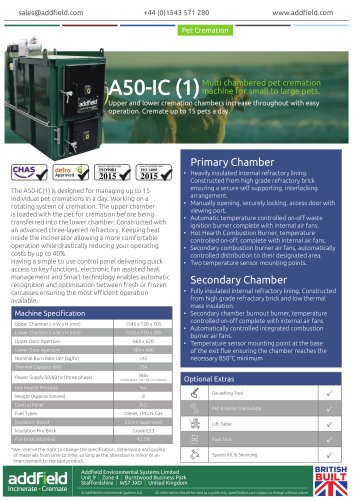

A50-IC (1)

3 Pages

-

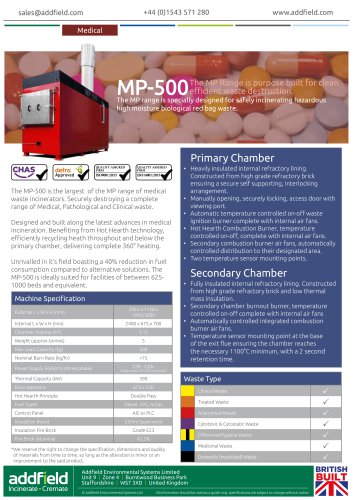

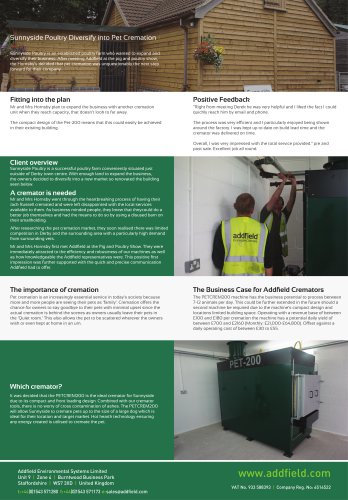

Pet Cremation

6 Pages

-

TB

3 Pages

Archived catalogs

-

Lambing Season

1 Pages

-

Keeping Saudi Arabia safe

1 Pages

-

Invaded by Japanese Knotweed

1 Pages

-

Containerised Pet Crematoria

1 Pages

-

Treasured Friends Case Study

1 Pages

-

INDIVIDUAL CREMATOR

5 Pages

-

Large Incineration Solutions

8 Pages

-

N20-AA

5 Pages

-

N20

5 Pages

-

PHOENIX 2

5 Pages

-

PHOENIX 1

5 Pages

-

N20-SA

5 Pages