Catalog excerpts

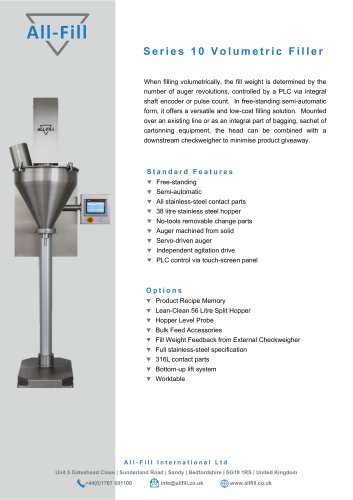

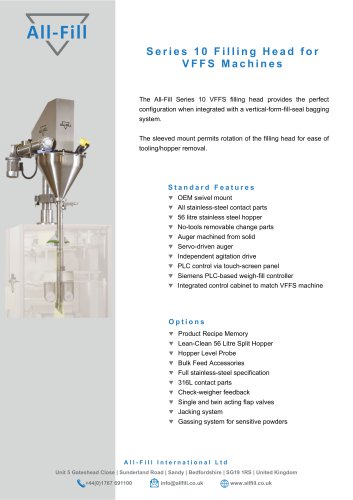

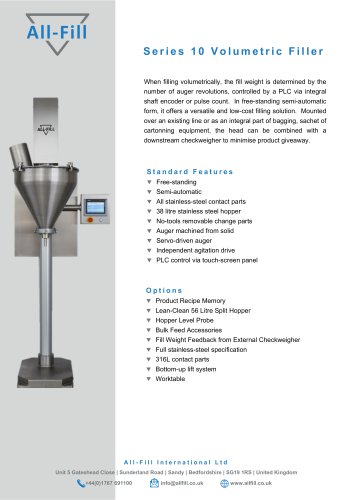

Series 10 Volumetric Filler When filling volumetrically, the fill weight is determined by the number of auger revolutions, controlled by a PLC via integral shaft encoder or pulse count. In free-standing semi-automatic form, it offers a versatile and low-cost filling solution. Mounted over an existing line or as an integral part of bagging, sachet of cartonning equipment, the head can be combined with a downstream checkweigher to minimise product giveaway. Free-standing Semi-automatic All stainless-steel contact parts 38 litre stainless steel hopper No-tools removable change parts Auger machined from solid Servo-driven auger Independent agitation drive PLC control via touch-screen panel Product Recipe Memory Lean-Clean 56 Litre Split Hopper Hopper Level Probe Bulk Feed Accessories Fill Weight Feedback from External Checkweigher Full stainless-steel specification 316L contact parts Bottom-up lift system Worktable All-Fill International Ltd Unit 5 Gateshead Close | Sunderland Road | Sandy | Bedfordshire | SG19 1RS | United Kingdom +44(0)1767 691100

Open the catalog to page 1

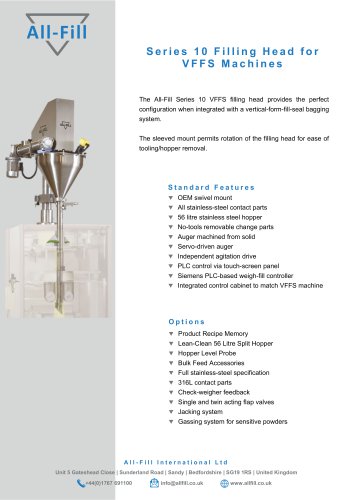

Series 10 Volumetric Filler Fully enclosed stainless steel cover Separate drive to slow speed agitator Direct drive to auger with integral encoder Electrically interlocked inspection cover Optional large capacity 56 litre split hopper Siemens PLC control via touch-screen HMI No-tools self-aligning hopper release handwheel No-tools quick-release auger and funnel Standard Specification Controller type: HMI: Hopper capacity: Agitation drive: Agitation options: Siemens PLC Colour touch-screen panel 38 litres 0.55kW Continuous With fill only With fill and time delay No agitation Auger revs:...

Open the catalog to page 2All All-Fill International catalogs and technical brochures

-

Series 1 Micro-Fill

1 Pages

-

Pharma Brochure

6 Pages

-

Series 10 Gravimetric Filler

2 Pages

-

Series 10 Volumetric Filler

2 Pages

-

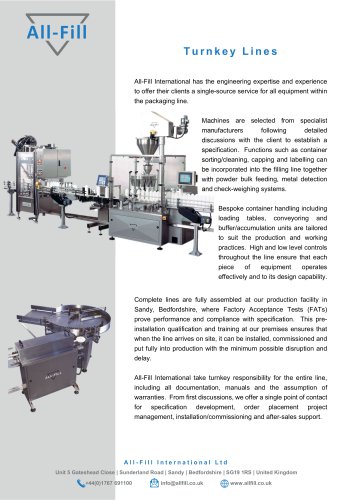

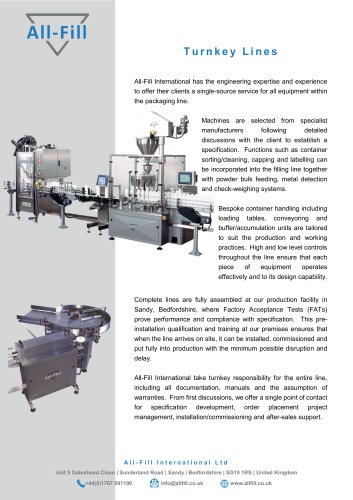

T u rnkey Lines

1 Pages

-

Pharma

6 Pages