Catalog excerpts

Series CMR Continuous Motion Rotary Systems The Series CMR continuous motion rotary fillers offer high-speed, high accuracy filling for a wide variety of powders and granules. With turret sizes from 500mm PCD to 2m carrying 12 to 48 transfer funnels, production output up to 400 containers per minute can be reached. One, two, three and four filling head configurations are available, dependent upon the size of container neck opening and powder flow characteristics. All-Fill’s Continuous Motion Rotary systems fill exceptionally cleanly. The powder is progressed from the client’s bulk feed system into the container via a completely sealed turret. The fillers can be offered with fully integrated check-weighing and reject systems, together with full feedback to the filling head. The fill weight performance of the filling machine can be displayed in ‘real-time’ graphical form on the touchscreen HMI. All powder contact parts are recess-free for easy cleaning and can be removed and re-assembled speedily without the use of tools. Containers handling parts are quick-release and colour-coded for super-fast changeovers. Dust-free filling Quick-release, no-tools changeover FDA approved silicone “flex-seals” Auger machined from solid All stainless steel contact parts Turret jogging system Servo-driven auger Servo-driven main turret Independent agitation drive Fully enclosed dust retention and extraction system PLC control via touch-screen panel 1 to 4 filling heads 12 to 48 transfer funnels Vibration or pulsed air technology Check-weigher or laser level feedback Integrated tare-and-gross weighing Piano reject system Lean-Clean 56 Litre Split Hopper Hopper Level Probe Bulk Feed Accessories Full stainless-steel specification 316L stainless steel contact parts All-Fill International Ltd Unit 5 Gateshead Close | Sunderland Road | Sandy | Bedfordshire | SG19 1RS | United Kingdom +44

Open the catalog to page 1

Series CMR Continuous Motion Rotary Systems Powder flow characteristics will determine the system of transfer from the funnel into the containers. Where vibration is employed, only the lower funnel section and the container is jogged, reducing inertion and noise levels. With small doses of sticky powders, AllFill’s unique pulsed air technology prevents bridging and sticking in the funnels. For glass bottles and other containers of inconsistent weight, integrated tare-and-gross weigh systems provide 100% net weight validation. S e r ie s C M R C o n t i n u o u s Motion Rotary Filling M ac h...

Open the catalog to page 2All All-Fill International catalogs and technical brochures

-

Series 1 Micro-Fill

1 Pages

-

Pharma Brochure

6 Pages

-

Series 10 Gravimetric Filler

2 Pages

-

Series 10 Sack Filler

2 Pages

-

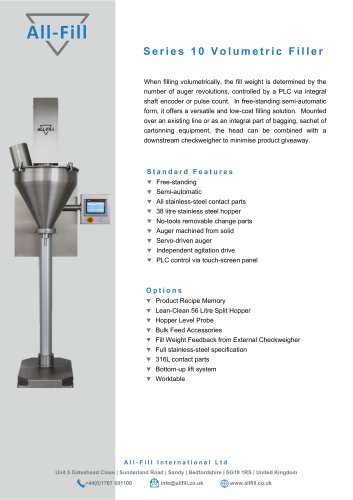

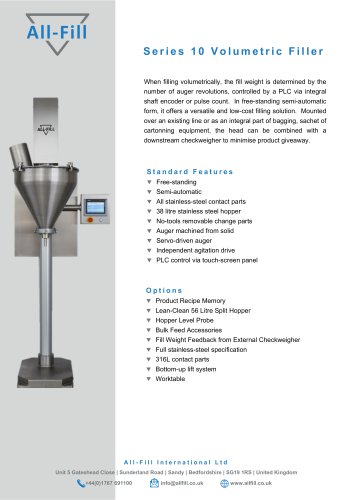

Series 10 Volumetric Filler

2 Pages

-

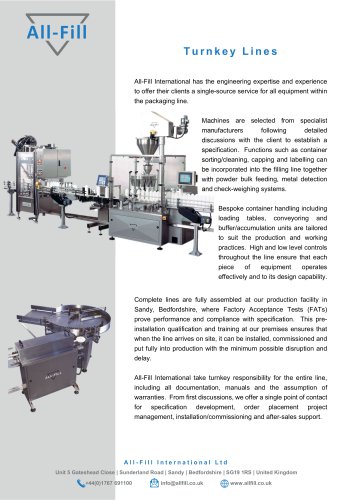

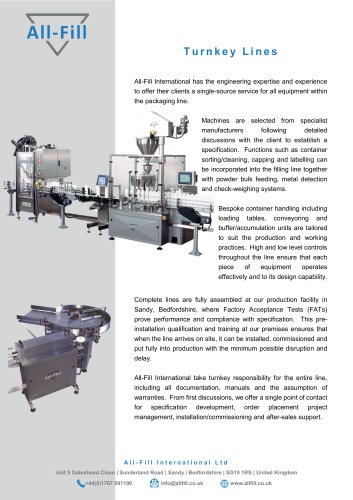

T u rnkey Lines

1 Pages

-

Pharma

6 Pages