Website:

BANDELIN electronic

Website:

BANDELIN electronic

Catalog excerpts

3 4 High-power ultrasound Intensive cleaning for Industry – Service – Maintenance 1 60 years of experience in ultrasound

Open the catalog to page 1

Overview Find out about our new ultrasonic cleaning units and see them in action. Comprehensive consultation is guaranteed by our experts. Generators, oscillating systems and reactors are for a hands-on experience. BANDELIN electronic is represented at many major trade fairs at home and abroad, for example at the HANNOVER MESSE, Turning-Days, AMB, parts2clean and SURFEX. Contents Ultrasonic cleaning page 3 Applications page 4 SONOREX TECHNIK selection of units page 5 The extablished – industrial units RM page 6 The convenient – industrial units RM page 7 The two-parts – industrial units ZM...

Open the catalog to page 2

Ultrasonic cleaning ECONOMICAL Regular ultrasonic cleaning saves money. Material to be cleaned will last longer due to the more gentle effect of ultrasound resulting in less needed spare parts. Faster cleaning times reduce standstill periods between productions. EFFICIENT Ultrasonic cleaning processes are effective. Optimum cleaning results will be achieved. Brushing and wiping is no more necessary. The material to be cleaned – including its surfaces – will not be damaged. Even intricately shaped parts can be cleaned. FRIENDLY TO THE ENVIRONMENT Biologically degradable cleaning agents are...

Open the catalog to page 3

Applications 3 4 RM / ZM Typical industrial applications Precision mechanics Cleaning of stainless steel, brass and aluminium parts Industrial safety and re protection Cleaning of respirator masks and sooty parts Mechanical engineering Cleaning and degreasing of bearings, crankshafts, double-sided plates, work pieces, electrostatic lters Wood working industry Cleaning of wood working tools and maintenance of machine parts Pharmaceutical industry Cleaning of metal lters and tabletting tools Medicine technology Cleaning of dentures, implants and joints Automobile industry Cleaning of...

Open the catalog to page 4

3 4 selection of units Three product lines with different congurations for application in industry, craft and service Constantly increasing demands on product quality require also adequate ultrasonic equipment featuring sophisticated technology and high exibility. BANDELIN offers a variety of SONOREX TECHNIK equipment for individual cleaning requirements that meet todays demand for high quality, economic efciency and environment associated factors. • Units with ultrasound and heating (UH) – for cleaning. The heating supports the cleaning effect of the chemistry. • Units with ultrasound (U)...

Open the catalog to page 5

The established – industrial units RM One-piece ultrasonic units from 13 to 210 litres • Welded cleaning tank made of 2 mm stainless steel AISI 316 Ti • Weir oating contamination like particles, oil and grease can be removed from the bath surface using an oil separator • Filling level mark well recognizable imprint for the minimum lling level of the cleaning uid • Additional outlet for connection of an oil separator or for emptying the uid behind the weir • Drain for 3-way ball valve for emptying or relling the tank or connecting to a ltration • Heating on/off with pilot lamp, temperature...

Open the catalog to page 6

The convenient – industrial units RM One-piece ultrasonic units from 115 to 230 litres Basic equipment analogue to RM 110 – 210 welded cleaning tank made of 2 mm stainless steel AISI 316 Ti, ultrasound, heating, lling level mark, welded drain, overow weir with drain, drip-proof housing made of stainless steel AISI 304 • Spraying pipe generates in connection with an oil seperator a movement on the liquid’s surface that leads oating oil and grease from the bath surface into the overow weir • Liquid level switch as dry run protection for heating and ultrasonic transducers • Ultrasonic...

Open the catalog to page 7

The two-parts – industrial units ZM Two-part industrial ultrasonic units from 115 to 230 litres also available in TwinSonic®-versions as multi-frequency units with ultrasonic transducers at the bottom and at one side. Heating on/off with pilot lamp, temperature thermostatically adjustable from 30 to 80 °C Why two-parts? • • • • Separate installation of generator apart from the wet area The generator is equipped with a serial interface and a remote control connection for external control Operation of several cleaning tanks fed by one generator is possible, even if each tank works with a...

Open the catalog to page 8

Accessories Accessories Insert baskets MK protect the parts to be cleaned and the unit against damage. Lid MD made of stainless steel, to protect the liquid from contamination. Model RM 16 RM 40 RM 75 RM 112 ZM 112 RM 110 RM 182 ZM 182 RM 180 RM 212 ZM 212 RM 210 MK 16 B MK 40 B MK 75 B MK 110 MK 180 MK 210 Insert basket load up to 40 kg - MK 40 S MK 75 S MK 110 S MK 180 S MK 210 S Insert basket for lifting device MK 16 B MK 40 B MK 75 B MK 110 B MK 180 B MK 210 B - MK 40 BS MK 75 BS MK 110 BS MK 180 BS MK 210 BS Lid MD 16 MD 40 MD 75 MD 110 MD 180 MD 210 Drop plate between 2 units TB 16 TB...

Open the catalog to page 9

Additional equipment Oscillation MO The electrically driven oscillation MO enables automatic movement of the basket in tanks of the production line RM 16 or RM 40. The oscillating movement of the parts intensies the cleaning efciency of the ultrasonic irradiation and helps to remove dirt particles more efciently. Model RM 16 RM 40 Oscillation MO 16.2 MO 40 Tank rack for 1 unit WO 16-1 - Additional equipment MO 16.2 Further tank racks WO on request. Tank rack WO The tank racks are designed for up to 4 units of the production line RM 16, in connection with oscillation MO 16.2. WO 16 Lifting...

Open the catalog to page 10

Peripheral units Filtration FA To be connected to the ultrasonic cleaning tank. Removed particles are retained by lter. This prolongs the use of the cleaning liquid while its cleaning capacity remains unchanged. Oil separator OX To be connected to the ultrasonic cleaning tank, if oil and grease has to be removed. Dirt accumulations oating on the bath’s surface are led via the weir into the oil separator and are separated by gravitation. DI-water treatment WA To be connected to a rinsing bath in order to remove stain making water residues on the cleaned parts. Trough dryer TO The cleaned...

Open the catalog to page 11All BANDELIN electronic catalogs and technical brochures

-

RK 255 / H

3 Pages

-

RK 106

3 Pages

-

RK 52 / H

3 Pages

-

SONOREX DIGITEC DT 1028 / H

4 Pages

-

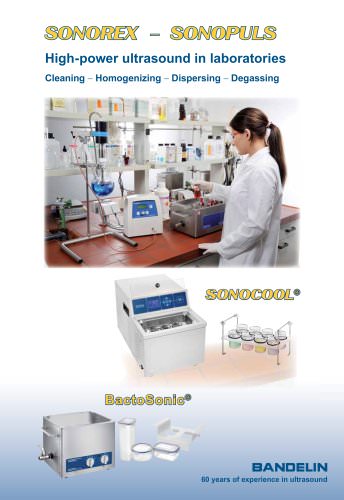

SONOCOOL 255

2 Pages

-

TRISON 4000

4 Pages

-

TRISON

2 Pages

-

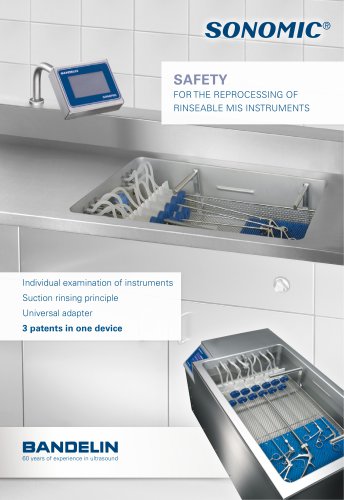

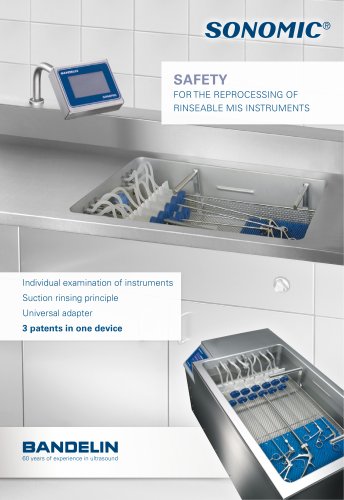

SONOMIC® SAFETY

12 Pages

-

SONOMIC® MC 1001

2 Pages

-

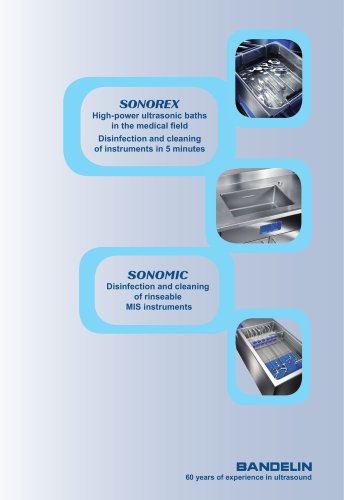

SONOREX

16 Pages

-

Ultrasonic reactors

8 Pages

-

SONOREX TECHNIK

28 Pages

-

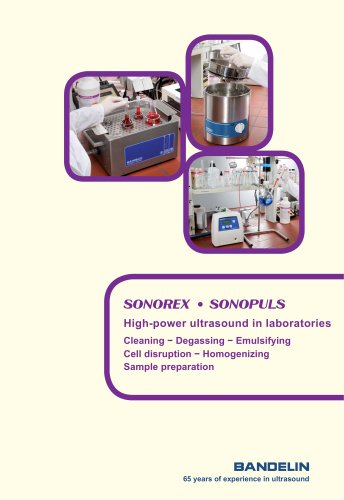

SONOREX SONOPULS

36 Pages

-

SONOMIC

12 Pages

-

SONOREX SONOMIC

20 Pages

-

Sonorex - Sonoplus

28 Pages

-

Sonomic

12 Pages