Website:

BAUMER

Website:

BAUMER

Group: BAUMER

Catalog excerpts

FORMOLDEHYDE & STEAM STERILIZER HI VAC MX II Tightness □ Hospitalar - Stainless Steel □ Biological - Stainless Steel Air Compressor □ Compressed air system (standard) □ Compressor bs-04-01(separate) Accessories □ Load rack □ Rack trolleys □ Wire mesh baskets □ Floor support □ Wall support Installation Components □ Steam valve system □ Sanitary filter for steam □ Water valve □ Water treatment □ Compressed air valve □ Electric panel Services □ Points installation □ Replacement Parts Kit □ Validation □ Preventive Maintenance □ Training □ Extended Warranty □ Qualification □ Gamp 5 Documentation Folder SELECTION Useful space of the chamber (Medium) □ B0112-140 - 460 x 460 x 660 mm □ B0112-200 - 460 x 660 x 660 mm □ B0112-263 - 460 x 460 x 1245 mm □ B0112-370 - 460 x 660 x 1245 mm □ B0112-418 - 660 x 660 x 960 mm □ B0112-542 - 660 x 660 x 1245 mm □ B0112-716 - 660 x 660 x 1645 mm □ B0112-890 - 660 x 660 x 2045 mm Thickness of the chamber □ 4,763 mm (3/16”) □ 7,938 mm (5/16”) Chamber Material □ Stainless steel 316L □ Stainless steel 316Ti Chamber Finish □ Polished (standard) □ Electropolished Application □ General sterilization □ Low temperature □ Cycles for Lab □ Special cycles Printer □ Matrix Printer □ Thermal Printer Recorder / Supervisor □ Recorder □ Control System Supervisor Control Sensor □ Additional sensor on the jacket □ Sensors with RBC calibration certificate Electric Power □ 220 V □ 50 Hz Door configuration □ One door □ Two doors for barrier instalation Steam Feeding □ Direct steam (standard) □ Switching (Direct steam + Steam Generator) □ Steam Generator 18 kW / 30 Kg/h □ Steam Generator 36 kW / 60 Kg/h □ Steam Generator 44 kW / 73 Kg/h □ Steam Generator 52 kW / 86 Kg/h □ Steam Generator 72 kW / 120 Kg/h □ Steam Generator with industrial steam pipe coil Vacuum System □ Liquid ring vacuum pump 1,5 hp □ Liquid ring vacuum pump 3,0 hp □ Liquid ring vacuum pump 4,0 hp □ Liquid ring vacuum pump 5,0 hp □ Liquid ring vacuum double stage pump 3,0/5,0 hp □ Dry vacuum pump 3,0 hp Piping □ Stainless steel threaded □ Tri clamp (TC) Stainless steel Proportional Integral Derivative Valve □ PID Heat Exchanger □ Heat Exchanger Lateral closing □ Without closing (standard) □ Stainless steel Upper closing □ Without closing (standard) □ Stainless steel Back closing □ Without closure (standard) □ Stainless steel APPLICATION The HI VAC MX II sterilizer is designed to attend the highest sterilization parameters following international manufacturing regulations, allowing the sterilization of products which do not withstand the high temperature of the common sterilization processes, high density material such as surgical fields and apparel, instruments (wrapped or not) , utensils, glassware, gloves, syringes, rubbers, liquids in airtight bottles or not, and liquids processed in quality control laboratories, with specific Bowie & Dick test and Leak Test indicated for use in hospitals, emergency departments, medical clinics, clinical analyses laboratories and quality control laboratories. It uses saturated steam from pressurized water with load conditioning phase through the removal of air by vacuum pulses and steam pressure and vacuum drying. MODELS AND CAPACITY HI VAC MX II line is composed of small, medium and large sterilizers. B0112-140 - Approximate capacity: 140 l B0112-200 - Approximate capacity: 200 l B0112-263 - Approximate capacity: 263 l B0112-370 - Approximate capacity: 370 l B0112-418 - Approximate capacity: 418 l B0112-542 - Approximate capacity: 542 l B0112-716 - Approximate capacity: 716 l B0112-890 - Approximate capacity: 890 l Sterilizers may be supplied with a formaldehyde cycle for low temperature sterilization only in the models B0112-263, B0112-370 and B0112-54

Open the catalog to page 1

FORMOLDEHYDE & STEAM STERILIZER HI VAC MX II door or double doors, guillotine type, with vertical movements and automatic opening. MAIN CHARACTERISTICS Configuration by the user: The HI VAC MX II allows the configuration of the equipment at purchasing time, aiming a better adequacy of the equipment to the needs of the user. User Accessible programming: user configurable parameters through command interface and password. Guillotine type door: with vertical movement, automatically driven with no physical effort. Equipment may be configured with single or double door for installation at...

Open the catalog to page 2

FORMOLDEHYDE & STEAM STERILIZER HI VAC MX II independent from the control sensors. The Control system supervisor is able to print all process data in a printer, eliminating the need of a separate line recorder. Command Valves: control the entry of steam into the chamber and the drain outlet, independent and pneumatic driven, built in AISI 316 stainless steel, solenoid valves actuated by compressed air. Electric solenoid valves for controlling the other electrical supply lines. CONSTRUCTION Chamber: rectangular, built with double wall, with central crease and drop. The existing piping under...

Open the catalog to page 3

FORMOLDEHYDE & STEAM STERILIZER HI VAC MX II degree by degree variation; · Number of vacuum and steam pulses – between 1 and 99 pulses; · Vacuum pulse depth – between 0,9 a 0,05 bar absolute; · Steam pressure in the conditioning phase – between 1,0 a 2,0 bar absolute. · Exposure time between 1 and 999 min. · Drying time from 1 to 999 min. · End of cycle temperature – between 80°C and 99°C. Available only for cycle of liquids. COMPONENTS AND ACCESSORIES Configurable for all the HI VAC MX II models. Vacuum system: through a monoblock water-ring vacuum pump, optionally it can be supplied with...

Open the catalog to page 4

FORMOLDEHYDE & STEAM STERILIZER HI VAC MXTABLE: ENGINEERING DATA HI VAC MX II Not*: Th. drain mutt br connected to the drain*)* line independent!, from the building sewerage. The gauges displayed are those of the equipment connections. The dimensions of the supply piping must b

Open the catalog to page 5

FORMOLDEHYDE & STEAM STERILIZER HI VAC MX II TABLE WITH EQUIPMENT PLAN, VIEW AND PERSPECTIVE LOAD SIDE UNLOAD SIDE LOAD SIDE Hnlwn operational dstorce Mrlnuri operational distance s a I Av. Arnolfo de Azevedo, 210 • Pacaembu • Sao Paulo/ SP • 01236-030 • Caixa Postal: 1081 Tel: 11 3670 0000 • Fax: 11 3670 0053 aumer . . | www.baumer.com.br • e-mail: cmlbh@baumer.com.br

Open the catalog to page 6All BAUMER catalogs and technical brochures

-

Prostheses

36 Pages

-

LED SURGICAL FOCUS - QUANTA

2 Pages

-

Conquest Vertex

4 Pages

-

Steam Sterilizer HI VAC II

6 Pages

-

Trolleys and Racks

2 Pages

-

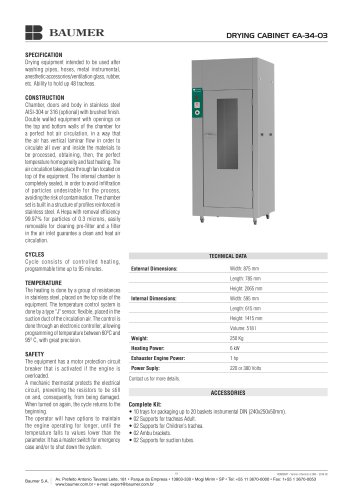

Drying cabinet EA-34-03

1 Pages

-

Ultrasonic Reprocessor

5 Pages

-

BIPOLAR

3 Pages

-

Quanta

2 Pages

-

SAB 4000

2 Pages

-

C ONTROLE DE INFEC ÇÃ O

24 Pages

-

SPEED II

6 Pages

-

VEGA

8 Pages

-

Vega MAXX

4 Pages

-

CYGNUS

2 Pages