Catalog excerpts

Chamber useful dimension (average) Control Sensor □ Sensors with RBC calibration certificate Electric Supply Power Door Configuration □ Two doors for pass-through installation Anti-crushing System □ With anti-crushing system Steam Supply □ Direct steam (Standard) □ Switch (direct steam more steam generator) Vacuum System □ Liquid ring vacuum pump 1,5 hp □ Liquid ring vacuum pump 3,0 hp Front Cabinet □ Painted finish (standard) Lateral closing □ Without closing (standard) Back Closing □ Without closing (standard) □ Network compressed air (standard) □ R0100-040 Compressor (built-in the equipment) □ Wire mesh baskets □ Tray support (100/210 models) Installation Components □ Network steam rack □ Steam sanitary filter □ Gamp 5 Documentation Folder Steri lizer designed to meet the most critical steril ization parameters and normative parameters of manufacture and security, being able to sterilizer and dry materials of density such as surgical fields and clothes, packed or unpacked instruments and tools, glasses, gloves, syringes, rubbers, liquids in open vials with F0 calculation, mainly necessary in quality control laboratory with specific program for Bowie & Dick Testand Leak Test. Recommended for use in hospitals, emergency rooms and outpatient care centers, medical clinics, medical analyses laboratories and quality control laboratories. It uses saturated steam from pressurized water with load conditioning phase with air removal through vacuum pulses, steam pressure and vacuum drying. The HI SPEED II family is composed by small, medium

Open the catalog to page 1

STEAM STERILIZER HI SPEED II MAIN CHARACTERISTICS User setting: The HI SPEED II family allows the equipment to be set at the purchase, searching for the best adequacy of the equipment to each user’s needs. User accessible programming: User-configurable parameters through command interface by password. Door: Guillotine type door, with vertical movement, manually driven with no physical effort. The equipment can be set with single door or double door for passthrough installation. Chamber: built with double wall and isolation in Bidim. Pipeline: Existing pipeline welded in the chamber, in AISI...

Open the catalog to page 2

STEAM STERILIZER HI SPEED II Inner chamber drain: protected with 1” diameter filter in perforated stainless steel plate. It is located at 300 mm from the door flange on the non-sterile side. Frontal cabinet of sterilizer: built in carbon steel plate with corrosion protection and painting. Optionally, the cabinet can be supplied in stainless steel plate with brushed finish. Side closing (optional): The equipment can be supplied with no sides for installation between a double pass-through, enabling free access for maintenance; and optionally with sides in stainless steel plates or in carbon...

Open the catalog to page 3

STEAM STERILIZER HI SPEED II The component can be set at the moment of the order with pump options of 1.5 hp and 3.0 hp. Steam supply: Equipment with possibility of double steam supply, with supply through central boiler and commutation for supply through incorporated electric generator, when required. Commutation of steam supply between central boiler and electric generator, controlled by IHM. Steam generator: Optional, the generator is built in AISI 316L stainless steel, with automatic supply through water centrifugal pump. The generator has thermal insulation through rock wool blanket...

Open the catalog to page 4

STEAM STERILIZER HI SPEED II TABLE: ENGINEERING DATA Door Quantity Filtered water (f1) Liquid ring vacuum pump (Single Medium/peak consumption (I/h) Pressure (kg/cm²) Connection Ø Deionized water (f2) Medium/peak consumption (I/h) Pressure (kg/cm²) Steam (h) Pressure (bar abs) Medium/peak consumption (kg/h) Connection Ø Compressed air (j) Connection Ø Pressure (kg/cm²) Medium/peak consumption (I/h) Electricity with generator Voltage (V) Frequency (Hz) Power (kW) Sem gerador Voltage (V) Frequency (Hz) Power (kW) Dimensional Chamber Dimensions (cm) Size Useful (I) Size utter Number of Baskets...

Open the catalog to page 5

STEAM STERILIZER HI SPEED II TABLE WITH EQUIPMENT PLANT, VIEW AND PERSPECTIVE MINIMUM DISTANCE ONLY ON LEFT SIDE LOAD SIDE Minimum operating Distance Minimum operating Distance 0,60 m LOADING SIDE UNLOADING SIDE FRONT VIEW SIDE VIEW REVERSE OSMOSIS OPTIONAL PARTITION POSITION Minimum operating Distance MASORY POSITION Minimum operating Distance PLANT VIEW LOADING SIDE Av. Arnolfo de Azevedo, 210 • Pacaembu • São Paulo/ SP • 01236-030 • Caixa Postal: 1081• Tel: 11 3670 0000 • Fax: 11 3670 0053 www.baumer.com.br • e-mail: cmlbh@baumer.com.br

Open the catalog to page 6All BAUMER catalogs and technical brochures

-

Prostheses

36 Pages

-

LED SURGICAL FOCUS - QUANTA

2 Pages

-

Conquest Vertex

4 Pages

-

Steam Sterilizer HI VAC II

6 Pages

-

Trolleys and Racks

2 Pages

-

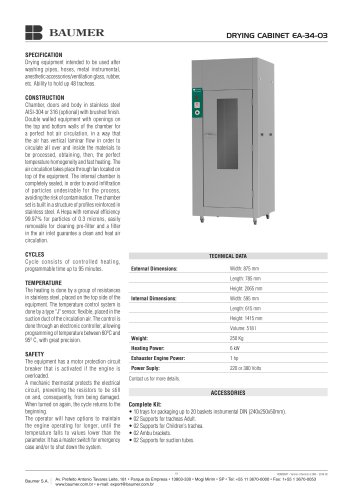

Drying cabinet EA-34-03

1 Pages

-

Ultrasonic Reprocessor

5 Pages

-

BIPOLAR

3 Pages

-

Quanta

2 Pages

-

SAB 4000

2 Pages

-

C ONTROLE DE INFEC ÇÃ O

24 Pages

-

VEGA

8 Pages

-

Vega MAXX

4 Pages

-

CYGNUS

2 Pages