Catalog excerpts

BAUMER Ultrasonic Reprocessor BAUMER Ultrasonic Reprocessor SELECTION Chamber useful dimension □ E0201-042 - 700 x 300 x 200 mm □ E0201-080 - 670 x 300 x 200 (Double sink) Voltage □ 220V Frequency □ 50 Hz □ 60 Hz SPECIFICATION • The Ultrasonic Reprocessor RU - E0201 is indicated for cannulated or non-cannulated instrument cleaning (options described on the screen before each cycle), using the ultrasound removal technology; • Through twelve piezoelectric transducers and an ultrasound generator, the sonic energy is produced by mechanic vibrations in the frequency of 40 kHz; • The temperature and the enzymatic content, together to the micro explosions generated by the sonic system, achieve and remove any type of dirt, even those in places inaccessible for brushes used in the manual cleaning. • Composed by the FLOW System that works from diaphragm pumps properly dimensioned and provides the dirt removal through mechanical forces of friction, pull and rubbing. • The FLOW system has specific adaptors for each cannulated instrument diameter, providing better cleaning efficiency; • Sink with rounded corners and polished finish, minimizing the accumulation of residue and maximizing the cleaning; • It has an automatic detergent dosing system; • It has an automatic drainage; • It has 10 automatic cycles, being the first four previously set; • It has a programmable logic controller with color Touch Screen of simple operation, which enables the operator to set each cycle phase; • Hinged lid, which enables full sealing through silicone gasket, and safety system that does not operate with the lid open; MODELS AND CAPACITIES E0201-042 - 42 liters capacity; E0201-080 - 80 liters capacity and double sink; MAIN CHARACTERISTICS • Chamber built in AISI-304 stainless steel, brushed. • Sink: Built in AISI 304 stainless steel (optionally in AISI 316), with rounded corners and sanitary polished finish. • Lid: Built in AISI 304 stainless steel (optionally in AISI 316). The lid sealing is done through a pure silicone rubber gasket and its articulation and restricted by a piston system. It has a safety system that prevents the door opening, avoiding risks to the operator. • Isolated command of the ultrasound generation system that prevents interference in the communication. • Two removable covers for maintenance being a front and one rear and a tilting side cover which gives access to the electrical panel. • Supported by leveling feet. • It has an automatic drainage system; • Connection filtered water inlet and purified in accordance with the RDC number 15 Art. 68. • It has an overflow pipe located on the rear top of the sink. • Internal basket with ten quick coupling adapter nozzles. • Adaptor cup for each cannulated instrument type, being the lid coupling diameter able to vary between 1 and 10 mm. COMMAND • It has a programmable logic controller with color Touch Screen of simple operation, which enables the operator to set each cycle phase. The user can set up to 10 cycles, including the configuration of the time parameter, temperature parameter and other parameters in the process phases. • The first four (04) cycles are previously fabric-set as a simple reference for the user. • The system provides basic conditions of distant communication through modem and/or supervisory system for remote maintenance integrated to the engineering (programmed maintenance) and/ or technical service support system from the manufacturer (supervisory system separately). • Registration system (optional) through an USB system for data collection or impressora termica. SAFETY • It has a level control system, in which the low level protects the resistor and transducers; • Resistor safety thermostat with manual set that prevents the resistance start-up in case of an over temperature; • Emergency bottom on the frontal panel, in case of failure of other safety devices; • Inductive lid closing sensor that prevents the cycle of starting with the lid open, avoiding potential burnings or contact with the cleaning solution. HEATING SYSTEM • It has a spiral resistance of 5KW, assembled in a heating boiler, in which a quantity of heat enough for an efficient heating is generated; • Working temperature at 60°C. PURIFIED WATER AND FILTERED WATER INLET SYSTEM • Through automatic water inlet system, where solenoids valves are started, releasing filtered and purified water inlet (according to user selection) until the work level is achieved, stopping, then the water entrance.

Open the catalog to page 1

BAUMER Ultrasonic Reprocessor OPERATION PRINCIPLE Rinse This phase consists in supplying the sink with water and placing the articles to be processed, closing the equipment lid and operating the sensor (TI). The water supply valve (SY-1 or SY-2) in the processing sink is activated until the level sensor achieves its working level. At this moment the activation of the Ultrasound (PT), Flow (P1) or circulation (P3) is enabled, provided that the functions had been programmed. After finalizing this phase, all the activated items are turned off, the drainage pump (P2) is enabled for 1 minute...

Open the catalog to page 2

BAUMER Ultrasonic Reprocessor GROUNDING PLAN NOZZLE SPRAY SYSTEM Cabinet built in AISI 304 STEEL, with 370 liters of capacity to store detergents and lubricants, designed to minimize the operator's efforts when removing the basket from the ultrasonic sink. It is possible to change the dimensions. Dimensions (meters): 1.0 x 0.6 x 0.62 Table built in AISI 304 STEEL, to support the ultrasound, with the possibility of using a sink with 0.8 x 0.4 x 0.25 (meters) of dimension in order to enable manual cleaning before placing the instruments inside the Automatic Ultrasonic Reprocessor. Dimensions...

Open the catalog to page 3

Ultrasonic Reprocessor PMC 2202 QUICK COUPLING E0203-004 Lid for Cannulated instruments Ø8 mm – 5 Pieces Lid for Cannulated instruments Ø9 mm – 901166 – 5 Pieces Lid for Cannulated instrument Ø10 mm – 901167 – 5 Pieces LID FOR CANNULATED INSTRUMENTS Ø1 mm E0203-009 Silicone lid in white. Passage hole of Ø6 mm. 6 mm engraved on the frontal side of the lid. Quantity – 5 pieces. Quick coupling used to lead water and detergent into the FLOW system, manufactured in acetal, which can be part of the basket set. PLC 23006 QUICK COUPLING E0203-005 Silicone lid in blue. Passage hole of Ø1 mm. 1 mm...

Open the catalog to page 4All BAUMER catalogs and technical brochures

-

Prostheses

36 Pages

-

LED SURGICAL FOCUS - QUANTA

2 Pages

-

Conquest Vertex

4 Pages

-

Steam Sterilizer HI VAC II

6 Pages

-

Trolleys and Racks

2 Pages

-

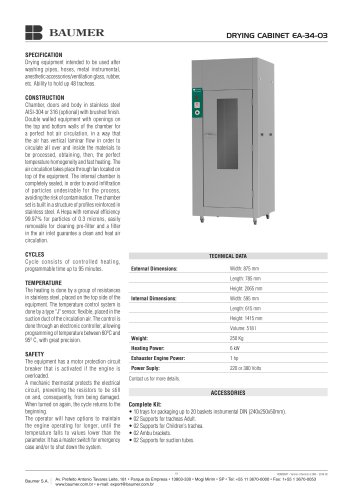

Drying cabinet EA-34-03

1 Pages

-

BIPOLAR

3 Pages

-

Quanta

2 Pages

-

SAB 4000

2 Pages

-

C ONTROLE DE INFEC ÇÃ O

24 Pages

-

SPEED II

6 Pages

-

VEGA

8 Pages

-

Vega MAXX

4 Pages

-

CYGNUS

2 Pages