Website:

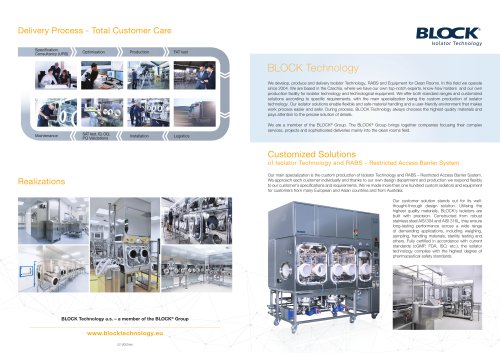

BLOCK Technology

Website:

BLOCK Technology

Catalog excerpts

VHP Decontamination Lock Material airlock providing rapid H₂O₂ decontamination

Open the catalog to page 1

Dimensions VHP Decontamination Lock VHP Decontamination Lock Dimensions in mm - VHP Decontamination Lock 1 Width Closing door height Swing door width Dimensions in mm - VHP Decontamination Lock 2 Width Closing door height Swing door width

Open the catalog to page 2

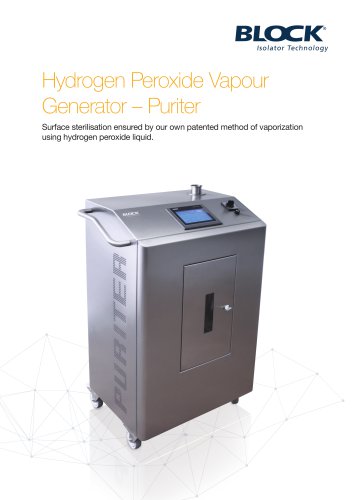

Decontamination locks are most frequently used as a pass-through to transfer material between rooms with different classes of cleanliness (typically B and C), whereas material must be decontaminated (by means of surface sterilization) before entry into the room. Loaded materials are decontaminated using hydrogen peroxide vapour with a 6-log reduction. A hydrogen peroxide vapour generator is a part of the equipment. Integrated VHP generator Decontamination pass-through cabin may be fitted onto the wall separating individual rooms Lock complies with the leak tightness classes pursuant to ISO...

Open the catalog to page 3

Main switch H₂O₂ concentration sensor – high Process sensor inside the chamber. H₂O₂ concentration sensor – low Safety sensor inside the chamber. Chamber closing door 03 It is made of PMMA with a thickness of 25 mm. The door is sealed with a silicone pneumatic seal. A sensor monitors the closing of the door; another sensor controls the mechanism that prevents the door from opening. H₂O₂ concentration sensor – low Safety sensor outside the chamber. Perforated shelves 04 4 pieces, standard perforated shelves for loading material. Compressed air inlet Air exhaust Air inlet Paperless recorder...

Open the catalog to page 4All BLOCK Technology catalogs and technical brochures

-

BLOCK Technology_overview

2 Pages

-

BLOCK Technology_Company profile

21 Pages