Website:

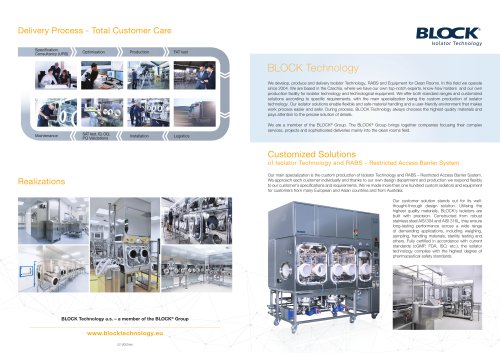

BLOCK Technology

Website:

BLOCK Technology

Catalog excerpts

Weighing Isolator Suitable for work with API / HAPI and for personnel protection.

Open the catalog to page 1

Dimensions Weighing Isolator Weighing Isolator Dimensions in mm - Weighing isolator Dimensions in mm - Working chamber Front height Working chamber total volume Working plate height Gloves position* Usable depth space Airlock total volume *Option to alter on request

Open the catalog to page 2

This isolator is designed for work with hazardous materials and is used for personnel protection. The main utilisations of the isolator are for weighing, sampling and handling hazardous materials. Dual-chamber weighing isolator Airlock with one glove allowing for loading of material and instruments Working chamber with three gloves intended for work with hazardous materials Leak tightness class 3 according to ISO 10648-2 “C” Class cleanliness according to EU GMP standard “Audit Trail” compliant Electronic control system for automatic adjustment of basic operating modes managed by Siemens...

Open the catalog to page 3

Turbulent Flow Commonly used for “C” and “D” classes of cleanliness where the direction of airflow is not clearly defined. The air flows in an irregular direction from the air supply inlet to the air outlet through cylindrical HEPA filters H14 at a filtering efficiency of 99.995%. The rate of air exchanges of clean air into the chamber usually ranges from 5 to 40 exchanges per hour. Fresh air G4 filtered air Hepa H14 filtered air Contaminated air Filtered exhaust air Hepa H14 filter Negative Pressure The HVAC system allows for the formation of negative pressure in the interior of the...

Open the catalog to page 4

Working chamber Airlock Built-in LED lights Built-in LED lights ensure illumination levels of at least of 500 lux. Tri clamp equipped for a continuous liner Main switch Service panel Pressure fuse The pressure fuse serves as a safety element indicating increased pressure in the chamber. In the event that the assigned pressure in the chamber is exceeded a pneumatic flap valve is opened and the pressure value is decreased without deterioration of internal atmosphere. Sensors for monitoring safe closure of the window 14 15 Cable glands Cable glands are mounted in the isolator wall. Sockets for...

Open the catalog to page 5

Hinged door Front window The door allows for material transfer from the chamber to the surroundings or from the chamber to other equipment (e.g. a fume hood). The hinged door is operated with the help of a door latching mechanism. The door is made from AISI 316L stainless steel, safety glass and silicone sealant. Visual and acoustic alarm Inflatable sealing, safety glass fitted with sleeved flanges. Sensors for monitoring safe window closure. A gas spring assists with easy opening. Valve for removing liquid waste from the 05 chamber A beacon light and an acoustic alarm providing a quick...

Open the catalog to page 6

Sliding door Sliding trays The door allows material transfer between chambers. It is operated with a foot switch or with a control touch display. Door action is performed by a pneumatic valve. The door is fitted with inflatable sealing. For improved ergonomics and easy transfer of material, the airlock is fitted with a sliding tray. Rounded edges/corners inside the working chamber Rounded corners and highly polished surfaces allow for easy cleaning of the chamber. The chambers are precision-welded which guarantees their leak tightness. Easy cleaning of the isolator is made possible with an...

Open the catalog to page 7

This isolator control system is operated with a Siemens colour touch screen. The Simatic control system from Siemens together with a foot-operated switch creates an intuitive and user-friendly experience. The screen displays the actual parameters of the environment and monitors emergency statuses. The system includes remote access for customer service support. As required, it is possible to implement connection to an additional device for production data storage and export. User Login and automatic log-off countdown timer Illumination control icons Chamber interior physical values...

Open the catalog to page 8All BLOCK Technology catalogs and technical brochures

-

BLOCK Technology_overview

2 Pages

-

BLOCK Technology_Company profile

21 Pages