Catalog excerpts

understanding bioprocesses Monitor your process in real-time – with BlueInOne Measurement of CO2, O2, pressure, humidity for: OUR CER RQ

Open the catalog to page 1

Just one device for the parallel online measurement of: • 02 and C02 • Humidity • Pressure • No minimal gas flow needed • Pressure automatically compensated o^e (Q) v Gain information about your process in real-time*: CER, OUR, RQ Biomass Growth rate Xs, Yxs *The usability of the soft sensors requires the BlueVis software and depends on the set-up of the process and may require additional equipment. Soft sensors by EXPUTEC® GmbH.

Open the catalog to page 2

I monitor several parallel fermentation processes in real-time with BlueInOne analyzers. For me, this is the most convenient way to be on the save side. Contemporary bioprocessing is frequently involving the use of parallel processes. Each BlueInOne is dedicated to one process, allowing a very large amount of data to be obtained continuously and without interruptions, and practically eliminating the risk of inter-process contamination. 3

Open the catalog to page 3

We purchased the BlueInOne since it is well established and very well proven in the field. And there are many other compelling arguments for this analyzer. The BlueInOne sensor series is used by an overwhelming number of companies and universities since many years. The analyzers have proven themselves as tough and highly reliable. The majority of the renowned fermenter manufacturing companies like Sartorius®, Eppendorf®, INFORS HT®, Applikon® Biotechnology are also distributing the BlueInOne.

Open the catalog to page 4

Know your process: • Gain vital information about your running process. Change your “black box" process into a well characterized. • High grade of automation in your bioprocess. • No sampling and no multiplexing means no danger of contamination. • One analyzer per process means that you get a continuous real-time measurement without interruptions. Nothing will be overseen and you are in time with the process. • Get alarmed if sampling/testing of the process is needed. • The BlueinOne is reasonably priced. • Understand your process in real-time to save time. • No personnel expenses for...

Open the catalog to page 5

Use all features with the new BlueVis software Unified bioprocessmanagement LOGGING & VISUALIZATION SENSORS & PROBES Blue PROCESS SOFTWARE Pumps Feeding Mass flow controller PROCESS PARAMETERS Biomass by EXPUTEC® Growth rate by EXPUTEC

Open the catalog to page 6

With the new BlueVis software, we use all the features of the analyzer and get access to vital process parameters in real-time. For me, this is essential to control the process. With the new BlueVis you are now able to manage your bioprocess. You can connect the BlueInOne and other sensors and probes to log and to monitor all vital data in real-time. BlueVis will process the data and calculates key parameters via integrated soft sensors. The data from the BlueInOne can be used to calculate CER, OUR and the RQ. BlueVis is able to optimize and control your process via connectable pumps,...

Open the catalog to page 7

Get you bioprocess connected with BlueVis Input: BluelnOne series and all other BlueSens sensors: • H2, CH4, EtOH • Probes for: pH, pMeOH, pEtOH, p02 • Glucose/Lactate analyzer Process control: • Pumps • Temperature • Mass flow • Feeding rates • Stirrer Your advantages: Connect all kind of probes and sensors to BlueVis • Run up to 12 parallel bioprocesses • Visualization of the of the data • Easy to use • Overview of all current measuring results • Log all data • Provide all data and calculations via OPC Output: Logging and visualization of all measurements • CER, OUR, RQ • Biomass by...

Open the catalog to page 8

Your demands The BluelnOne series is currently comprised of two models, the BluelnOne Ferm and the BlueInOne Cell. The two models have got different oxygen sensors, therefore allowing them to take reliable measurements under a variety of process conditions. The BlueInOne Ferm is using an oxygen meter based on a zirconium dioxide sensor. BlueInOne Cell, in contrast, measures the oxygen concentration by a galvanic cell. Otherwise, both models are identical. Which sensor might be best suited for your process depends on the process conditions, the accompanying gases which are produced and the...

Open the catalog to page 9

Mechanical connection: • Easy installation in exhaust line • Various standardized hose nozzles, quick connector, Swagelok, Tri-Clamp • Connections for all types of mechanical connections on request Data Output: • RS485, RS232, USB, 2x 4-20mA signals • OPC (with BlueVis) • Once a data line and the power supply have been connected, and the mechanical attachments have been connected, measurements using BlueInOne can begin A convenient external display for the BlueInOne: • See the current CO2 and O2 concentrations • Start the calibration • No separate power supply needed

Open the catalog to page 10

In our laboratory experiments change from time to time. The BluelnOne is easy to install and also easy to dismount from a fermenter so I can use it for different applications and for various scales. The BlueInOne gives me all the flexibility I need for all my different setups.

Open the catalog to page 11

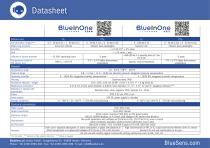

BluelnOne CELL Sensor unit * FS= full scale ** depends on flow adapter dimension ***others on request BlueSens gas sensor GmbH • Snirgelskamp 25 • 45699 Herten • Germany Phone: +49 2366 4995-500 • Fax: +49 2366 4995-599 • E-mail: info@BlueSens.de

Open the catalog to page 12All BlueSens gas sensor GmbH catalogs and technical brochures

-

BCpreFerm

5 Pages

-

BCP-O2

2 Pages

-

BCP-H2

2 Pages

-

BCP-CO2

2 Pages

-

CO2 in-situ measurement

8 Pages

-

BCP - CH4

2 Pages

-

BCP-CH4 Brochure

6 Pages

-

BlueVary Brochure

8 Pages

-

BlueSens General Brochure

12 Pages