Website:

BMT Medical Technology

Website:

BMT Medical Technology

Group: MMM Group

Catalog excerpts

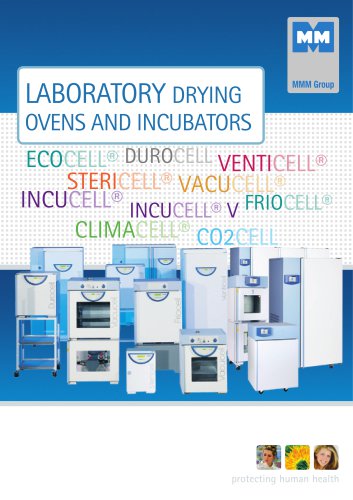

VACUCELL® With Vacuum Temperature sensitive, easy decomposable or oxidative materials can be dried very tenderly in VACUCELL® vacuum drying ovens, where there is the opportunity of extrusion of air by inert gas. Also complicated components with hardly accessible hollow spaces are drying quick and effectively in VACUCELL® ovens. Ideal for drying of samples to constant weight. Special application of the device is possible mainly in the fields of plastics processing, pharmaceutical, chemical, electro technical and other industries. Laboratory drying ovens Volume: 22, 55, 111 litres Working temperature: 5°C above ambient temperature up to 200°C Door window Integrated duct for sensors etc. (∅ 40 mm) Inert gas connection Needle valve for fine dosing Pressure resistant inner chamber Safety valve-door VENTIFLEX Interior: stainless steel, mat. No. 1.4571 (AISI 316Ti) The Versatile Standard Line with Microprocessor Control Unit • base box Vacustation • chemicaly resistant vacuum pump • chemicaly resistant vacuum pump with inlet separator and exhaust condenser • built-in vacuum control system • Electronic pressure measuring and indication on the display • special software WarmComm 4.0 • separate PT 100 sensor • stainless steel casing of the devices 3 adjustable programs RS 232 – interface for printer or PC-communication delayed heating start and stop function acoustic and visual alarm in error state time range 99 hours 59 minutes digital safety thermostat manual control of the air exhaust flap programme cycles … standard line The High-Tech Comfort Line with Multi-Functional Microprocessor Control Unit Options • • • • • • • • • • • • • • 6 adjustable programs chip card system for individual program storage RS 232 – interface for printer or PC-communication delayed heating start and stop function acoustic and visual alarm in error state time range 0–40 years with 1 min intervals digital safety thermostat real time selectable rate of temperature increase or decrease – “RAMPS” programming of program time segments – “SEGMENTS” programme cycles manual control of the air exhaust flap keyboard blocking door opening control • base box Vacustation • chemicaly resistant vacuum pump • chemicaly resistant vacuum with inlet separator and exhaust condenser • built-in vacuum control system • Electronic pressure measuring and indication on the display • BMS relay alarm contact • special so

Open the catalog to page 1

Technical data Note: All technical data are related to 22°C ambient temperature and ± 10% voltage swing (if not specified). • not measured *) The mains voltage is shown on the unit type label. **) The heat in vacuum is transferred to the goods on the shelves by conduction in the shelves, therefore the mentioned temperature deviations are valid for temperatures on the surface of the shelves, there must be a perfect heat-conducting contact between the temperature sensors and the shelf surface. Goods placed on the shelves must also be in a perfect contact with the shelves, the goods...

Open the catalog to page 2All BMT Medical Technology catalogs and technical brochures

-

CLIMACELL® EVO

7 Pages

-

INCUCELL/INCUCELLV

2 Pages

-

FRIOCELL

2 Pages

-

CLIMACELL

2 Pages

-

CO2CELL

2 Pages

-

Heat technology

7 Pages

-

STERILAB

5 Pages

-

UNISTERI HP IL

11 Pages

-

UNISTERI HP

9 Pages

-

STERIVAP HP IL

9 Pages

-

STERIVAP HP

7 Pages

-

STERIVAP

7 Pages