Catalog excerpts

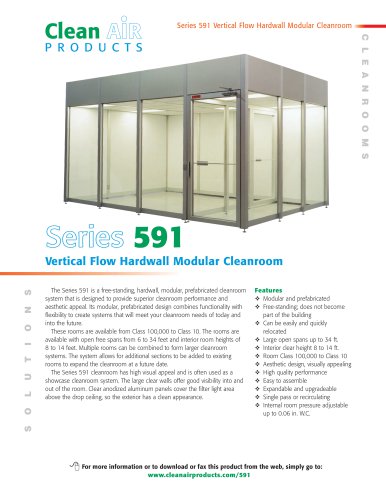

Series 591 Vertical Flow Hardwall Modular Cleanroom General Description The Series 591 is a free standing, rigid wall, modular, prefabricated cleanroom system designed to combine superior cleanroom performance with high visual appeal. The modular, prefabricated design melds functionality with flexibility to create systems that will meet your cleanroom needs today and into the future. Large open spans up to 24 feet (Special configurations up to 30 feet) Interior clear height 8 to 14 feet Room Class 100,000 to Class 10 Single pass or Recirculating Esthetic design, High visual appeal Easy to assemble High quality performance Modular, prefabricated Expandable and upgradeable The Series 591 is available from Class 100,000 to Class 10. Rooms feature open free spans from 6 to 34 feet and interior room heights of 8 to 14 feet. Multiple rooms can be combined to form larger cleanroom systems. The system allows additional sections to be added to existing rooms to expand the cleanroom to meet future needs. See the table at the end of this document for sizing formulas. The Series 591 cleanroom has high visual appeal and is often used as a showcase cleanroom system. The large clear, acrylic walls offer good visibility into and out of the room. Clear anodized aluminum panels cover the filter, light area above the drop ceiling so the exterior has a sleek, clean appearance. The rigid wall design allows the cleanroom to operate at higher internal pressures than may be found in other types of cleanroom systems. This pressure is adjusted through variable wall dampers that regulate the flow of air out of the room to control the internal room pressure. ISO specifications require room pressures for some medical device and pharmaceutical applications higher than what a softwall cleanroom can provide. Higher internal room pressure on non-recirculating rooms can reduce the infiltration occasionally caused by drafts flowing under the bottom of the curtains. The modular prefabricated design makes installation fast and easy. Factory installation is available, but simple step-by-step instructions and detailed installation drawings allow the rooms to be assembled using in house maintenance personnel. The room assembles with common hand tools. Holes are pre punched and predrilled so the room is assembled by lining up holes and installing screws, bolts and snap in extrusions. The room ships knocked down on compact skids. After a room has been installed, its versatile modular design allows the room to be expanded, relocated, reconfigured into a different shape or made into multiple smaller rooms. This versatility keeps your Series 591 cleanroom system an asset that keeps pace with your cleanroom requirements. The modular design of the Series 591 means that the cleanroom can be expanded, modified, reconfigured or even sold. It can have value through out its life. The cleanroom system is not typically considered part of the building and can often be depreciated faster than a built in cleanroom. Consult your tax adviser for specifics of the tax advantages. The removable wall panels are supported by a special heavy-duty 3 x 3 anodized aluminum support post with upper cross panels. Together these form a strong, decorative exterior wall system. Each support post is equipped with a leg-leveling glide to adjust for variations in floor level. The walls extend down to approximately 2 in. above the floor For more information or to download or fax this product from the web, simply go to: www.cleanairproducts.com/591

Open the catalog to page 1

Series 591 Vertical Flow Hardwall Modular Cleanroom Technical Data continued allowing air to be vented around the entire perimeter. Adjustable wall vents located between the bottom of the wall panel and the floor fine tune the room pressure. Addition may be required with some rooms with a higher total airflow. Exact room configuration for lower wall spacing, quantity and location of adjustable grills is subject to room size and class. The wall panels are available in the following materials: Clear Acrylic Translucent Acrylic Yellow Acrylic Clear ESD acrylic Polycarbonate White painted...

Open the catalog to page 2

Series 591 Vertical Flow Hardwall Modular Cleanroom duct for the motorized ceiling HEPA filters. This space is filled with HEPA filtered air being returned from the cleanroom. It also minimizes dust and other contamination from settling on top of the filters and lights keeping them semi clean. The metal roof panel has enough strength that it can be walked on by building maintenance personnel. No guard rails are provided as part of the cleanroom. Non Recirculating rooms The metal roof is a non-insulated metal top. The roof can be walked on by a service technician, but is not designed to...

Open the catalog to page 3

Series 591 Vertical Flow Hardwall Modular Cleanroom Technical Data continued makes for a tighter ceiling grid than conventional Butt Joint tee bar grids. In addition they are faster and easier to assemble than other types of tee bar grid systems. The motorized ceiling filters, lights and blank panels will install into this grid. The Class of the room is determined by the number of filters in the ceiling (air changes per hour). Flow thru lights are also available for applications where 100% ceiling filter coverage is required or where a filter and light need to be in the same location. The...

Open the catalog to page 4

Series 591 Vertical Flow Hardwall Modular Cleanroom receiving are to the area where the room is to be installed. Note. Loading dock (if none please advice also), truck restrictions, hallways, door sizes product is going through, second floor installation, special material handing requirements to avoid and problems when receiving the room. Installation The room reassembles using simple hand tools. Step by step instructions are provided. Holes are pre-drilled so that installation is just a matter of lining up holes and installing screws and bolts and snap in extrusions. Clean Air Products can...

Open the catalog to page 5

Series 591 Vertical Flow Hardwall Modular Cleanroom Technical Data continued Temperature of the existing space _______________ Is it air conditioned __________________________ Are building post going to be inside the cleanroom. _________ Heat load if equipment in room if known _________________________ Exhaust ________________________________ ____ Loading dock and path to cleanroom area. (can standard semi truck back up to your dock, can the longer support beams of the cleanroom turn all corners, receiving hours ____ Is the existing space sprinkled ____ Location of the electrical panels to...

Open the catalog to page 6All Clean Air Products catalogs and technical brochures

-

CAP-301

5 Pages

-

CAP-109BL

3 Pages

-

CAP-112

2 Pages

-

CAP-116

4 Pages

-

CAP-901

2 Pages

-

CAP-130

5 Pages

-

CAP-1532

5 Pages

-

CAP701

8 Pages

-

CAP-558

3 Pages

-

CAP-560

3 Pages

-

CAP-582

2 Pages

-

cap-550

4 Pages

-

cap-556

3 Pages

-

CAP-575

5 Pages

-

CAP-577

5 Pages

-

CAP1414

5 Pages

-

CAP1421

2 Pages

-

CAP1412

2 Pages

-

CAP-18

2 Pages

-

CAP701KD-ST

2 Pages