Catalog excerpts

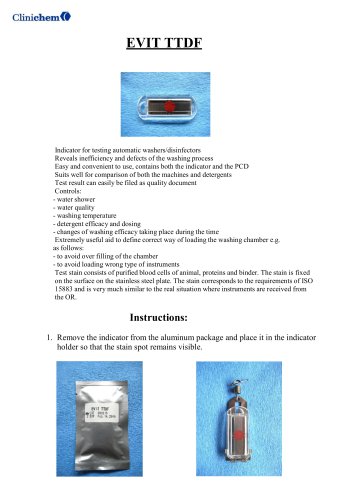

EVIT TTDF Indicator for testing automatic washers/disinfectors Reveals inefficiency and defects of the washing process Easy and convenient to use, contains both the indicator and the PCD Suits well for comparison of both the machines and detergents Test result can easily be filed as quality document Controls: - water shower - water quality - washing temperature - detergent efficacy and dosing - changes of washing efficacy taking place during the time Extremely useful aid to define correct way of loading the washing chamber e.g. as follows: - to avoid over filling of the chamber - to avoid loading wrong type of instruments Test stain consists of purified blood cells of animal, proteins and binder. The stain is fixed on the surface on the stainless steel plate. The stain corresponds to the requirements of ISO 15883 and is very much similar to the real situation where instruments are received from the OR. Instructions: 1. Remove the indicator from the aluminum package and place it in the indicator holder so that the stain spot remains visible.

Open the catalog to page 1

2. Fix the holder and the indicator in the side of the basket. The basket can contain instruments at the same time. 3. Place the basket into the chamber so that the EVIT is on one side of the chamber, however not close to the wall neither corners 4. Run standard washing cycle with drying, if drying available 5. Remove the holder from the basket and let it cool down for a while 6. Remove EVIT-system from the holder and the test plate from the plastic PCD 7. Evaluate the plate and compare the result to the instructions Test approved The stain is fully removed from the plate

Open the catalog to page 2

Test not approved Possible failures: Too low temperature, too low shower pressure or camber too full Actions: Check parameters, check the nozzles, check the washing arms, check the loading procedure. Test not approved Possible failures: Missing or lack of detergent or detergent not suitable. Also Actions: Check detergent pipes and connections. If necessary, proceed according to the actions described above 8. Save the indicator plate in the files as part of the quality assurance and documentation

Open the catalog to page 3

Recommended usage Once a week, always in the same position to find any changes in the process efficacy and possible need for service Always after repair and service of machine For checking and defining the optimum loading grade and method of the chamber Clinichem Oy Ltd. Hallitie 12 47400 Kausala p.05-381 8180 www.clinichem.fi clinichem@clinichem.fi

Open the catalog to page 4

Pictures: Correct loading of baskets and chamber

Open the catalog to page 5

Pictures: Incorrect loading of baskets and chamber

Open the catalog to page 6All Clinichem catalogs and technical brochures

-

EVIT TTDF

2 Pages

-

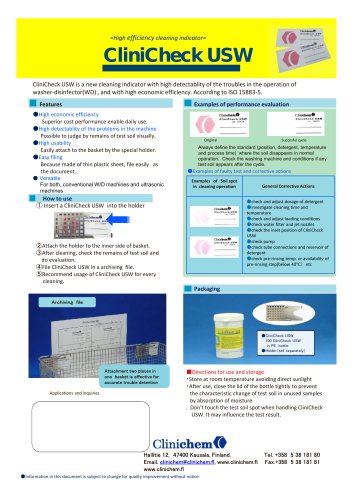

CliniCheck USW

1 Pages

-

Test pack

1 Pages

-

PT20

2 Pages