Website:

Cowellmedi

Website:

Cowellmedi

Catalog excerpts

COWELL® EXPERT INSTRUMENTS COWELL® Expert Instruments An Expert knows what makes the results

Open the catalog to page 1

• InnoGenic™ Autobone Harvester • Direct Surgical Guide Kit at makes the results An Expert knows wh

Open the catalog to page 2

COWELL® EXPERT INSTRUMENTS An Expert knows what makes the results Designed to perform maxillary sinus lifting. Aqua Membrane Lifter, Drill designs and Stopper System prevent perforation of sinus membrane. The kit includes all the instruments required for both crestal and lateral approach. Used for the immediate and effortless extraction of the root of the tooth with simple procedures. Sinus Lift Kit This revolutionary kit contains US Patented Modified Tap Drills and Spreaders in order to allow any dentists to easily lift, split or condense surrounding bone with simple drilling. Dentists can...

Open the catalog to page 3

MFS KIT [KSA004] > A comprehensive kit to approach direct & indirect maxillary sinus lift simply. Aqua Ratchet Connector Point Ø2.2 Crestal Drill Stopper Crestal Drill Aqua Lifter Aqua Syringe Connector Bone Carrier Aqua Tube Bone Condenser Depth Gauge Torque Wrench Sinus Elevator Lateral Stopper Lateral Drill Side Cutter

Open the catalog to page 4

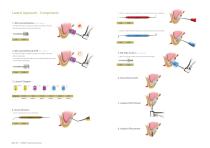

Crestal Approach - Components 4. Crestal Drill Stopper > Connected with a stopper to be drilled to the same length of the cartilage height of maxillary sinus which is measured by CT. > If not equipped with CT, fasten the stopper one step lower than expected and gradually increase the length. > Use to mark the point of perforation on cortical bone. > In the case of the remaining bone height is as low as 3.5mm, pay more attention when drilling. 3.5mm 7mm Drilling Depth Drilling Depth 2. 2.2 Twist Drill 800~1,000 rpm > Use for making guide hole before using the Crestal Drill. > Connect the...

Open the catalog to page 5

Crestal Approach - Drilling Sequence > Placing implant over Ø 4.0 is highly recommended. > Use the Torque Wrench to fix the Aqua Lifer Drill in the hole formed using Crestal Drill. Code Point Drill > Insert bone graft material using the Bone Carrier. Soft Bone Ø2.8 Crestal Drill Normal Bone If you need to expand hole, drill 1mm deeper using the crestal drill. Point Drill > After connecting the stopper with the Bone Condenser, Ø2.8 Crestal Drill Soft Bone Ø3.3 Crestal Drill Normal Bone elevate bone graft materials to inside of maxillary sinus. > Rotate bone graft material using the Bone...

Open the catalog to page 6

Lateral Approach - Components > CSE-02 : as stepwise, after using CSE-01, used for elevation of sinus membrane. > Drill after fastening the stopper according to the height of the bone. > Round shape to prevent membrane perforation. > CSE-03 : as stepwise, after using CSE-02, used for elevation of sinus membrane. 2. Ø6 Lateral Round Drill 800~1,000 rpm > Drill after fastening the stopper according to the height of the bone. > Round shaped edge. > When you expand window, must be connected with Stopper. > The residual bone should be replaced in the original position after drilling, sinus...

Open the catalog to page 7

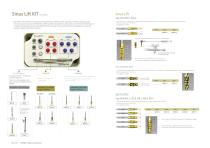

Sinus Lift Tap Drill (Ø3.6 ,Ø4.6) > Sinus Lift Kit is the world’s most innovating kit for performing maxillary sinus lift, ridge splits, and bone condensing cases. This revolutionary kit contains US Patented modified Tap Drills and Spreaders in order to allow any dentists to easily lift, split, or condense surrounding bone with simple drilling. Dentists can expect more predictable results, and patients can enjoy less traumatic surgeries with shorter chair time. > The Tap Drill uses low speed and high torque to grind through the maxillary bone, and safely elevates sinus without membrane...

Open the catalog to page 8

Sequence -Sinus Lift Immediate Implantation and Sinus Lift Technique with Tap Drill (Ø5.0 Fixture) Only use of Sinus Lift Drill 1. Sinus Lift (Ø4.0 Fixture) Cortical Bone piece after perforation by the Tap Drill Sinus Membrane Cortical Bone Use as Final Drill when placing Ø4.2~Ø4.5 fixture (Drilling under 30 rpm) Ø3.6 Drill Drill Speed : 20~30 rpm Torque : 45 N.cm Recommend to lift under 3mm Recommend to use Sinus Lift Drill and Spreader Drill together Ø2.2 Drill Bone Graft Fixture Placement Point Drill Drill Speed : 800~2,000 rpm Drill Speed : 20~30 rpm Torque : 45 N.cm Bone Graft using...

Open the catalog to page 9

Note Ridge Split and Block Bone Augmentation Technique with Spreader Drill (Ø4.0 Fixture) > Recommend to use Sinus Lift Drill and Spreader Drill together during the Sinus Lift operation. > Easily operate by using Ø3.2 Spreader rather than Point Drill. > Avoid to over press surrounding alveolar bone using Final Drill before fixture placement in D2. Point Drill Bone Graft Final drill Sequence-Spreader Drill Speed : 20~30 rpm Torque : 45 N.cm COWELL® Expert Instruments Ø4.0 Fixture Recommend to use Tapered Fixture Use Round Bur or Chisel etc. Mark the placing area

Open the catalog to page 10

1. Fixture Removal System Connect the F/R Screw to the FRS Driver. Connect the F/R Screw mounted FRS Driver to the fixture (clockwise 40~60 N.cm) and remove the FRS Driver. > Easy removal of fractured fixture / screw / abutment. Abutment Removal System Connect the Fixture Remover to the F/R Screw (counterclockwise). Remove the fixture after connecting the Torque Wrench (counterclockwise, 100~400 N.cm). To remove the fixture from the Fixture remover, use such device as vise to fix the Fixture Remover and connect to the Torque Wrench. Abutment Remover After connecting the FRS Driver to the...

Open the catalog to page 11

Reverse Drill & Screw Remover If the screw could not be removed by the Talon Drill Used when the thread inside the fixture is occluded and damaged. Form the hole on the fractured screw (depth 1~2mm / counterclockwise / 1,200~1,400 rpm). Reproduce the thread using the Tap Repair. Use the Screw Remover according to the created drill hole, remove the screw by pressing force (counterclockwise, 80 N.cm). Slot Driver Used for the damaged solid abutment (1piece type), healing abutment and cover screw. Form a slot on the surface of the damaged abutment using round bur. Connect the Slot Driver to...

Open the catalog to page 12All Cowellmedi catalogs and technical brochures

-

COWELL® Implant Solution v.29

137 Pages

-

InnoGenic™ Wifi-Mesh

26 Pages

-

Diaderm® M

3 Pages

-

MEGA DERM™ Plus

3 Pages

-

DIABONE

3 Pages

-

INNO OSS & INNO OSS Allo

3 Pages

-

INNO-CaP

3 Pages

-

COWELL® BMP

6 Pages

-

COWELL® Regenerative Solution

13 Pages

-

InnoGenic™ Bone Carrier

5 Pages

-

Volume-up™ Guide System

4 Pages

-

AO4 Surgical Stent

3 Pages

-

Direct Surgical Guide Kit

7 Pages

-

Atraumatic Extraction Kit

6 Pages

-

COWELL® BMP Trephine Kit

4 Pages

-

InnoGenic™ GBR Kit

7 Pages

-

Sinus Lift Kit

5 Pages

-

Digital Prosthesis (InnoFit)

13 Pages

-

Digital Prosthesis (SFIT)

14 Pages

-

InnoFit® Lodestar Kit

7 Pages

-

InnoFit® Lodestar Plus Kit

11 Pages

-

COWELL® Digital Products

39 Pages

-

Surgical Kit

11 Pages

-

Bite Impression Coping Catalog

10 Pages

-

SONATOR™ 80’s

16 Pages

-

Multi S & A Abutment

20 Pages

-

Beauty-up™ Abutment

31 Pages

-

Ball Abutment System

15 Pages

-

Mini Plus® Implant

5 Pages

-

INNO External Implant

9 Pages

-

INNO Internal Impant

12 Pages

-

INNO Submerged Narrow Implant

10 Pages

-

INNO Submerged Implant

18 Pages

-

COWELL® Implant System

66 Pages