Catalog excerpts

BASE 2-3 USER AND MAINTENANCE MANUAL C.I.E. DENTALFARM s.r.l. Via Susa, 9/a - 10138 TORINO - ITALY TECHNICAL & SALES SERVICE - (+39) 011/4346588 AFTER-SALE SERVICE - 011/4346632 FAX 011/ 4346366 E-mail: info@dentalfarm.it Website: www.dentalfarm.it

Open the catalog to page 1

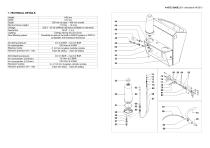

1. TECHNICAL DETAILS Height Width Depth Net and Gross weight Voltage Absorption Lighting Dust filtering system 445 mm 415 mm 305 mm at base – 400 mm overall 11,8 Kg – 14,3 kg 230 V - 50 Hz (different tensions available on demand) 60 W - 1,4 A Energy-saving 42 LED circuit Possibility to add-on the built-in WAFIS system or PRO-3; compatible with traditional extractors Devesting pressure Air consumption Blasting nozzle Abrasive grainsize min - max min 2,5 BAR - max 6,0 BAR 100 l/min at 4 BAR ∅ 3,0 mm tungsten carbide nozzles mesh 80 (200µ) – mesh 36 (500µ) Microblasting pressure Air...

Open the catalog to page 2

EXPLODED DRAWING AND SPARE PART LIST BASE 3 - table 2 BASE 3 is a sandblasting unit designed for devesting and finishing operations in the Dental and Jewellery field. The main features of the machine are: the ergonomic layout of the working chamber, the safety of use, and the trouble-free structure of the mechanical installation. BASE 3 is equipped with useful accessories and ensures a fast, practical and accurate work. The unit consists of a devesting projector and of 2 EASY tanks, featuring a pressure release system and an instant stop of the blasting jet. The unit can thus operate with...

Open the catalog to page 3

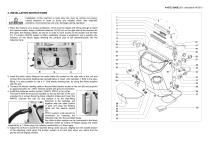

Installation of this machine is quite easy but must be carried out paying utmost attention in order to avoid any mistake which may originate problems, inconveniences and even damages during operation. 1. Place the machine on a proper workbench, which must be stable and strong enough to stand the machine safely. Keep a sufficient distance (10/15 cm) on the right side of the machine for the pipes, the feeding cables, as well as in order to have access to the shutter and the filter (F). If a built-in WAFIS system is fitted, preferably choose a workbench and a position (for instance on the...

Open the catalog to page 4

DESCRIPTION COMPLETE LED LIGHTING SYSTEM LIGHTING SYSTEM BASE ELECTRONIC BALLAST 42 LED CIRCUIT LIGHTING SYSTEM COVER PVC WASHER FOR HINGE HINGE FIXED PART HOLE 6mm HINGE MOVABLE PART PIVOT FOR HINGE SUCTION HOSE JOINT FOR SUCTION HOSE POLYCARBONATE WINDOW FOR BASE MODELS CONF. x 6 GLASS PROTECTION SCREEN PROTECTION SCREEN FIXING CLIPS GLASS JOINT WORKING CHAMBER DEVESTING PROJECTOR COMPLETE PROJECTOR SUPPORT SUPPORT FOR 2 MICROPROJECTORS COMPLETE MICROPROJECTOR (specify colour and nozzle) CLIP MALE KNOB M4x10 ABRASIVE FILTERING GRID PLASTIC RING D. 14 PLASTIC CAP D.=31 LOWER CLOSURE RUBBER...

Open the catalog to page 5

Very fine abrasives are highly sensitive to moisture and must be stored in a dry place, after the can has been accurately sealed and the dessiccant packet has been duly introduced into the can (if needed, replace them periodically). When filling the abrasive tanks, check the condition of the abrasive product; if the moisture content is too high (bad flowability and presence of clots), it is recommended to heat the abrasive in order to allow it to dry up completely. It is also of utmost importance to check the condition of the compressed air which in no way must contain evidence of moisture...

Open the catalog to page 6

A10723 BASE 2-3 - lotto/batch 04/2013 Problem: NO AIR COMES OUT FROM THE PROJECTOR (devesting) Possible cause Remedy The internal projector nozzle is Remove the cap and clean the injector. clogged. Solenoid valve is clogged. Close air inlet, remove the coil and the core and clean; eventually get in touch with our Technical Service. Problem: NOZZLE-HOLDER CAP COMES OUT DURING WORK (devesting) Possible cause Remedy Both piping and nozzle are clogged. Close up the end of the nozzle and press the footcontrol; the operating air flow will thus be inverted, eliminating any obstruction from inside...

Open the catalog to page 7

A10723 BASE 2-3 - lotto/batch 04/2013 Replacement of parts subject to wear (pipe, pipe-fittings, microprojector body) The polyurethan pipe, the connection fitting and the microprojector body where abrasive flows will inevitably wear out and need to be replaced regularly. To replace the microprojector body, follow the same instructions specified for the nozzle; to replace pipes or pipe-fittings, capsize the unit and work under the container. It is also possible to disconnect each tank for easier operation, simply unscrewing the nuts fixing it to the housing. Replacement of tank internal...

Open the catalog to page 8All Dentalfarm Srl catalogs and technical brochures

-

PROMO 2018

6 Pages

-

IDEA & IDEA PRO (IT & EN)

16 Pages

-

PRODUCT CATALOGUE

24 Pages

-

PHOTOPOL PRO

4 Pages

-

ZIRKO-SURFIN 300k

4 Pages

-

vit

2 Pages

-

SHINE

4 Pages

-

SHINING BOX

4 Pages

-

Dentalfarm - Photo-Flask

4 Pages