Catalog excerpts

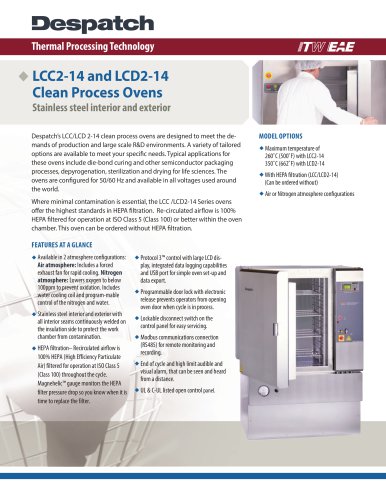

Thermal Processing Technology Clean Process Ovens Save valuable floor space Stainless steel interior and exterior The Despatch LCC/LCD stackable clean process ovens are designed to save valuable floor space and provide a variety of tailored options for your specific needs. Typical applications for these ovens include die-bond curing and other semiconductor packaging processes, depyrogenation, sterilization and drying for life sciences. The oven is configured for 220-240 volts, 1 phase, 50-60 hz. For production environment processes where minimal contamination is essential, the LCC and LCD Series ovens offer the highest standards in HEPA filtration. Re-circulated airflow is 100% HEPA (High Efficiency Particulate Air) filtered for operation at ISO Class 5 (Class 100) or better within the oven chamber. This oven can also be ordered without HEPA filtration. FEATURES AT A GLANCE u vailable in air or nitrogen atmosphere A configurations (100ppm oxygen capability). Forced exhaust is standard on all models for rapid cooling. Programmable control of the nitrogen and cooling water is standard on the nitrogen atmosphere units. u ockable disconnect switch on the control L panel for easy servicing. u rotocol 3TM control with large LCD P display, integrated data logging capabilities and USB port for simple oven set-up and data export. u tainless steel interior and exterior with S all interior seams continuously welded on the insulation side to protect the work chamber from contamination. u rogrammable door lock with electronic P release prevents operators from opening oven door when cycle is in process. u tackable design allows for S independent batch processing. u EPA filtration– Recirculated airflow H is 100% HEPA filtered for operation at ISO Class 5 (Class 100) throughout the cycle. Magnehelic™ gauge monitors the HEPA filter pressure drop so you know when it is time to replace the filter. u odbus communications connection M (RS485) for remote monitoring and recording. u nd of cycle and high limit audible E and visual alarm, that can be seen and heard from a distance. u L & C-UL listed open control panel U MODEL OPTIONS u wo sizes: 1.6 or 5.1 cu ft T u ith or without HEPA filtration W u ast rate HEPA filter F u ir or nitrogen atmosphe

Open the catalog to page 1

Chamber size (width x depth x height) * Clear opening width is reduced by 1.5” (3.8 cm) due to 3/4” (1.9 cm) shelf supports on each side. Capacity in cubic feet (liters) Overall size (width x depth x height) Electrical single phase 50/60 HZ * Heater capacity based on 240 volt supply. Operating at 208V will result in 25% reduction in heater output. 220-240 volts,* 15.5 amps Heater: 3 kW 220-240 volts,* 27.3 amps Heater: 6 kW Number of shelves provided Maximum number of shelves Shelf dimensions (width x depth) Approximate domestic shipping weight (export adds weight) PHYSICAL SPECIFICATIONS...

Open the catalog to page 2All Despatch Industries catalogs and technical brochures

-

Stands for Benchtop Ovens

2 Pages

-

LFC Class A Bench-top Oven

2 Pages

-

LAC High-Performance Oven

2 Pages

-

RAF Series Furnace

2 Pages

-

LBB Forced Convection Oven

2 Pages