Website:

EMUGE-Werk Richard Glimpel

Website:

EMUGE-Werk Richard Glimpel

Catalog excerpts

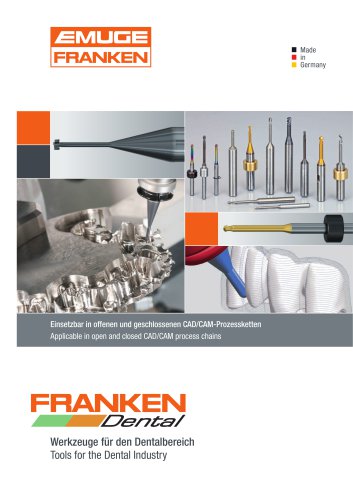

FRANKEN£P&/7t&/ FRANKEN-CIMT DENTAL TOOLS

Open the catalog to page 1

Lauf an der Pegnitz, Hometown of EMUGE-FRANKEN. WE TAKE INNOVATION TO THE LIMIT. Even our first threading tools impressed with the power of a new idea. A momentum that continues to inspire us to new levels of performance. Each innovation step leads to increased precision and higher quality – and results in solutions that provide key impulses for new production strategies. This constantly opens up new opportunities for value creation for our industrial partners worldwide.

Open the catalog to page 2

PRECISION IS IN OUR DNA. FOR MORE THAN 100 YEARS. EMUGE and FRANKEN have been developing cutting-edge technology in the field of precision tools for over 100 years. Today, the family-run EMUGE-FRANKEN group of companies is one of the world's leading manufacturers of threading, testing, clamping and milling technology products – for customers from the automotive, power plant and aviation industries to mechanical and plant engineering as well as medical technology. We are close to our customers in 60 countries through our own subsidiaries or sales partners. franken-dental.com/en/ Scanning the...

Open the catalog to page 3

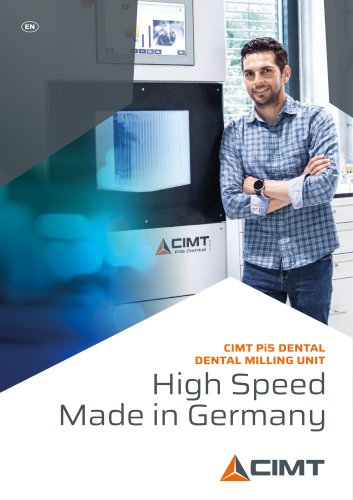

MILLING IN A SYSTEM ENVIRONMENT: FOR HIGH-END SYNERGIES. FRANKEN has developed the new FRANKEN-CIMT product line to utilise the extremely high dynamics of the CIMT Pi5 and Pi5 Turn dental milling machines: The tools were matched to the industrial performance level of the CIMT machines in terms of substrate, cutting edge geometry, finish treatment and coating. The result: Higher precision milling quality in significantly less time. Maximum accuracy of fit for dental workpieces – with minimised reworking thanks to extremely clean surface finishes. The ideal case of a perfectly balanced system...

Open the catalog to page 4

Bringing together what belongs together: The dental milling machine manufacturer CIMT Precision GmbH has been part of the EMUGE-FRANKEN group of companies since 2023. A match that is dedicated to precision and innovation. The industrial performance level of the CIMT Pi5 dental milling machine series enables full utilisation of the digital workflow in the dental laboratory. The worldwide customer base is supported by our application engineers. This team of experts provides the following services for the products offered by EMUGE-FRANKEN: ■ Worldwide phone consultation and support in solving...

Open the catalog to page 5

YOUR MATERIAL. OUR TOOL. The dental precision tools in the FRANKEN-CIMT product line are optimised for the latest dental materials. The range of applications for end mills, ball-nose end mills, torus end mills and twist drills includes common dental materials such as cobalt-chrome, titanium, PMMA / PEEK, wax and zirconium oxide. PMMA / PEEK SYMBOLS FOR TOOL APPLICATION. Design of cutting corner and face contour Recommended feed direction Recommended plunge angle (ramp angle) Ball-nose (full radius) Radius to be programmed in CAM Tool with corner radius FAST AND EASY GO TO THE WEBSHOP. You...

Open the catalog to page 6

BALL-NOSE END MILLS TORUS END MILLS END MILLS DRILLS

Open the catalog to page 7

FRANKENzy&s7t&/Carbide ball-nose end mills 2182AR For roughing, pre-finishing, finishing and machining residual material in cobalt-chrome. TIALN coating for longer tool life. High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy. Carbide ball-nose end mills 2177AR 05*0 ■ For roughing, pre-finishing, finishing and machining residual material in cobalt-chrome. ■ TIALN coating for longer tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy.

Open the catalog to page 8

Carbide ball-nose end mills 2176AR ■ For roughing, pre-finishing, finishing and residual material machining in cobalt-chrome. ■ TIALN coating for longer tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy. Carbide ball-nose end mills 2184LR Cobalt- ■ For finishing and machining residual material in cobalt-chrome. ■ ALCR coating for high wear protection and very long tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy. 0d1 r1 l2 l3 l1 l4 0d2 Neck angle a Flutes T-number Article...

Open the catalog to page 9

Carbide ball-nose end mills 2179AR For roughing, pre-finishing, finishing and machining residual material in cobalt-chrome. TIALN coating for longer tool life. High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy. ■ For roughing, pre-finishing and machining residual material in cobalt-chrome. ■ TIALN coating for longer tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy.

Open the catalog to page 10

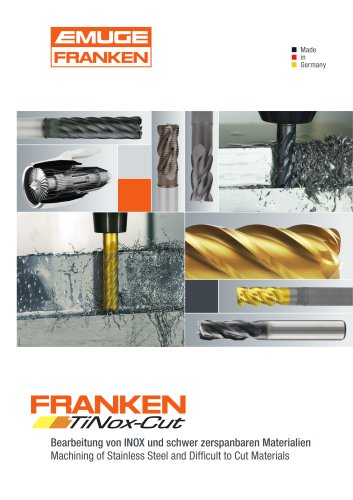

FRANKENzy&r7t&/ Carbide ball-nose end mills 2173TR ■ For roughing, finishing and machining residual material in titanium. TIN / TIALN coating for longer tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy. ■ With corner radius for roughing titanium. ■ TIN / TIALN coating for longer tool life.

Open the catalog to page 11

FRANKENzy&s7t&/Carbide end mills “Duplex” 2181AR Duplex for roughing in cobalt-chrome. The duplex geometry combines HPC and HFC geometry and enables 2D and 3D machining with just one tool. TIALN coating for longer tool life. ■ For finishing and machining residual material in cobalt-chrome and titanium. ■ ALCR coating for longer tool life.

Open the catalog to page 12

FRANKENzy&r7t&/ Carbide end mills 2186LR Cobalt- ■ For finishing and machining residual material in cobalt-chrome and titanium. ■ ALCR coating for longer tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy.

Open the catalog to page 13

Long version for roughing and finishing in titanium and cobalt-chrome. TIALN coating for best possible wear protection and long tool life. ■ For roughing, pre-finishing and machining residual material in cobalt-chrome and titanium. TIN / TIALN coating for longer tool life. ■ High accuracy radius tolerance of ±5gm for precise machining results and maximum repeat accuracy.

Open the catalog to page 14All EMUGE-Werk Richard Glimpel catalogs and technical brochures

-

Top-Cut Universal end mills

48 Pages

-

EMUGE Thread Cutting Technology

808 Pages

-

EMUGE Clamping Technology

176 Pages

-

FRANKEN Dental Tools

80 Pages

-

Dental tools News 2021

20 Pages

-

Micro

32 Pages

-

FIBER-cut

28 Pages

-

Milling Technology

440 Pages

-

Catalogue 520

672 Pages

-

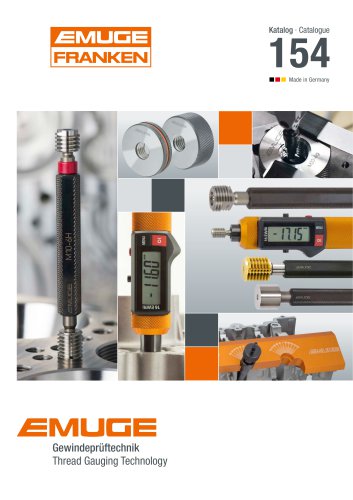

Thread Gauging Technology

104 Pages