Catalog excerpts

rming Erkoplast PLA-R, 1.5 mm, rose, hard Erkoplast PLA-R, 1.5 mm, rose, hard Erkoflex-bleach, 1.0 mm, soft Erkoloc-pro, 1.0 mm, soft/hard see occlusal splints see dressing plates Erkodur, 0.5 - 0.8 mm, hard Erkolen, 0.5 - 0.8 mm, elastic Erkodur-0M1/-A1/-A2/-A3, 0.6 - 2.0 mm, hard Erkocryl, 2.0 and 2.5 mm, hard Erkocryl, 1.5 and 2.0 mm, hard Erkodur, 1.0 - 2.0 mm, hard Erkoflex, 3.0 - 5.0 mm, soft Erkoflex, 1.5 and 2.0 mm, soft Erkoflex-bleach, 1.0 mm, soft Erkoloc-pro, 1.0 mm, soft/hard Erkoplast PLA-W/-T white and transparent, 3.0 (upper), 4.0 mm (lower), hard Erkolen, 1.0 and 1.5 mm, elastic Erkoplast PLA-W/-T white and transp., 3.0 (upper), 4.0 mm (lower), hard UZF-Cast, 0.1/0.15 mm Erkocryl Erkoflex. Erkoflex Erkoloc-Erkodur, Erkoloc-Erkodur, Erkodur Erkoflex Erkolign, Erkoloc-Erkoflex, Erkoflex 2.0 and 2.5 mm, hard 1.5 and 2.0 mm, soft -bleach, 1.0 mm, soft pro, 1.0 mm, soft/hard 1.5 - 5.0 mm, hard pro, 2.0 - 5.0 mm, soft/hard 1.5 - 5.0 mm, hard 0M1/-A1/-A2/-A3, 2.0 mm, hard -95, 2.5 and 4.0 mm, soft , 2.0 mm, tough-hard pro, 2.0 - 5.0 mm, soft/hard , 4.0 and 5.0 mm, soft -95, 4.0 mm, soft Erkodent Erich Kopp GmbH, SiemensstraKe 3, 72285 Pfalzgrafenweiler, Germany Tel.: + 49 (0) 74 45/85 01-0, Fax: + 49 (0) 74 45/20 92, info@erkodent.com, www.erkodent.com

Open the catalog to page 1

Ft Ft = Foil thickness (mm) Tft Tft = Thermoforming temperature (°C), Ht Ht = Heating time (min. sec.)

Open the catalog to page 2

Temperature and time indication for Erkoflex without insulating foil, see instructions Erkoflex-bleach transp., with insul. f. Erkoflex-95 transparent, with insulating foil Erkolen transparent, with insulating foil Erkolign transparent, with insulating foil Erkoloc-pro transparent, with insulating foil Erkoloc-pro blu blue-transparent, with insulating foil Erkoloc-pro green green-transparent, with insulating foil Erkoloc-pro pink pink-transparent, with insulating foil mm Erkoflex transparent, with insulating foil Order number (Contents) Order number (Contents) Order number (Contents)

Open the catalog to page 3

UZF-Cast, spacer foil for the casting technique

Open the catalog to page 4

* Order numbers for Erkoflex transparent, see Erkoflex Erkoflex-color Thickness 4 mm, order number (contents) (temperature and heating times see foil packaging) Colour bright red bright yellow bright blue bright green bright pink deep red dark blue light blue maroon deep green pure white deep black gold silver Freestyle colours Thickness 4 mm, order number (contents) (temperature and heating times see foil packaging) ' Freestyle Set und Freestyle-blackline Set (assorted, 5 pcs)

Open the catalog to page 5

PISS SAFE triple Thickness 5.5 mm, Erkoflex 2.5 mm (soft), triple layer 1.0 mm (hard), Erkoflex 2.0 mm (soft) (heating time: 3.45 min., thermoforming temperature: 110 °C, cooling time: 9.59 min.) Playsafe triple start set, 0 120 mm, 177 810: 1 Playsafe triple set with transparent foil, 1 Playsafe bite spacer, 1 Playsafe face chuck Playsafe triple set, 0 120 mm, 1 Playsafe triple foil (colour has to be Playsafe triple foils, 0 120 mm, 5 triple foils of the same colour (colour indicated), 1 label, 1 Erkobox, 1 sample FG-sheet, instructions has to be indicated), 5 labels, 1 sample...

Open the catalog to page 6

Selection of the right material thickness To select the right material thickness note that the thermoforming material looses 20 - 25 % of its original thickness when forming a model area of 1 cm height, for 2 cm height the loss is 30 - 40 %. For occlusal splints, the thickness is selected according to the desired verticalisation that possibly still allows a grinding-in without additional adjustment. Plastification in units without time or temperature control. • For most materials please proceed as follows: Check softness with instrument. If permanent impressions result, thermoform. •...

Open the catalog to page 7

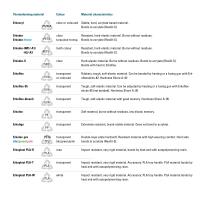

Thermoforming material clear or coloured Stable, hard, acrylate based material. Bonds to acrylate (Resilit-S). Erkodur Erkodur freeze Erkoloc-pro blu /green /pink Erkoplast PLA-R Erkoplast PLA-T Erkoplast PLA-W Material characteristics clear Resistant, hard-elastic material. Burns without residues. turquoise-transp. Bonds to acrylate (Resilit-S). tooth colour Resistant, hard-elastic material. Burns without residues. Bonds to acrylate (Resilit-S). Hard-elastic material. Burns without residues. Bonds to acrylate (Resilit-S). Bonds with heat to Erkoflex. Rubbery, tough, soft-elastic material....

Open the catalog to page 8

Tiefziehmaterial Playsafe triple foil Usig-Foil UZF-Cast Material characteristics Triple-layer plate soft/hard/soft. tooth colour, opaque Abrasion-resistant, very tough material. Glueable, bonds to acrylate. Spacer foils (shrinkage compensation) for the casting technique. Insulating foil for insulating and shrinkage compensation

Open the catalog to page 9All ERKODENT Erich Kopp catalogs and technical brochures

-

2021 Thermoforming

40 Pages

-

Program

28 Pages

-

silensor-sl

2 Pages

-

Thermoforming

40 Pages

-

Blocking out wax --

10 Pages

-

Playsafe comparison

6 Pages

-

New products 2015

12 Pages

-

tztG_EN

12 Pages

-

Playsafe Flyer

2 Pages

-

Machines (Unit)

4 Pages

-

New products 2013

12 Pages

-

Erkoform-3

1 Pages

Archived catalogs

-

Erkoform-3d

2 Pages