Catalog excerpts

Optimally prepared! What to consider when acquiring a marking laser The acquisition of a laser marker is a large investment for any organization. The correct choice of laser depends on many variables. The best prepared are the ones who maintain a full overview. Our checklist is designed to make your purchase decision as smooth as possible. Checklist for the acquisition of a marking laser What will be marked? □ Material/substrate (e.g. metal, plastic,...) □ Surface finish (e.g. matt, polished,...) □ Expected marking effect (e.g. type of marking, how light or dark, engraved, layer removal, etc.) Where and how should the marking take place? □ In a stand-alone workstation? (Laser marking system in laser safety class 1) □ In a production line (marking laser in safety class 4 would be integrated in a production line or machine) □ Will a laser-integrated vision system be required and beneficial? □ What additional workflows are needed (e.g. automatic mark alignment, quality assurance and control, code reading, OCV, mark traceability, inspection of marking for quality, positioning, ...)? Supplier of laser marking solutions □ Educate yourself with an overview of the various available technologies. □ Ask for a consultation on the relevant technologies and the calculation of your individual ROI. Sample marking □ Prepare samples with exact requirements (material, mark durability, mark timing, product life cycle, ...). □ Request a sample marking from the manufacturer. □ Test completed samples thoroughly (quality and contrast of the mark, legibility, traceability, ...). Systems und software □ Test the operator usability and all required functions in an application lab or showroom. □ Collect as much information as possible as a potential operator. Customer specific requirements □ Define requirements for traceability. □ Confirm capability to connect to your ERP system or database. □ Review the software for personal customization. □ Check availability and content of service packages, in order to minimize outages. □ Confirm possibilities for process validation and qualification of the laser marking system (e.g. IQ, OQ, PQ, MQ). □ Plan for training of administrators and operators. Collect quotes and make a decision! Scan and visit fobalaser.com → ALLTEC GmbH | FOBA Laser Marking + Engraving An der Trave 27-31 | 23923 Selmsdorf | Germany T + 49 38823 55-0 | info@fobalaser.com | www.fobalaser.com © 2017 ALLTEC GmbH – All rights reserved. Laser-purchase-Infographic-DE/EN 02.17 LASER KLASSE 4 LASER C

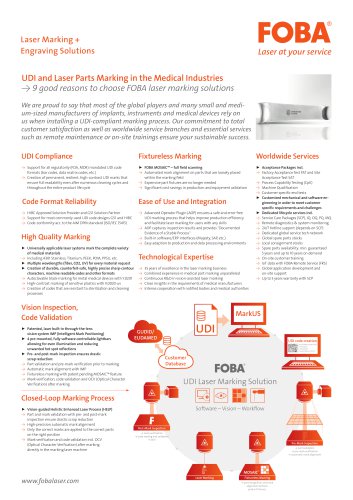

Open the catalog to page 1All FOBA Laser Marking + Engraving catalogs and technical brochures

-

Software and Vision overview

7 Pages

-

Service Packs Overview

4 Pages

-

Product brochure

4 Pages