Catalog excerpts

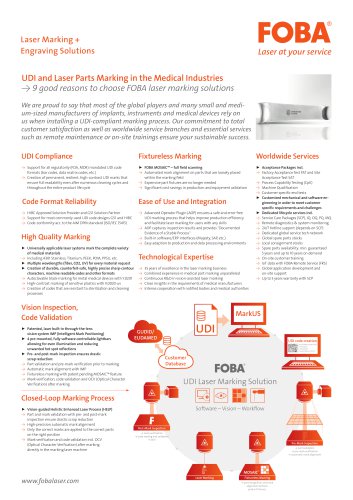

Laser Marking + Engraving Solutions FOBA Laser at your service Software, Vision and Workflow Overview High Performance Laser Marking Software with Laser Integrated Vision Alignment and Inspection Tools for the Simplest, Most Complete Laser Marking Process Solution

Open the catalog to page 1

Taking laser marking to the next level -Offering the market's simplest, most complete workflow solution Our intuitive high-performance laser marking software FOBA MarkUS takes laser marking to the next level of innovation by incorporating MOSAIC™, the latest patent pending mark alignment technology, into HELP (Holistic Enhanced Laser Process), the simplest, most intuitive and complete laser marking process solution available to the industry. Laser Marking Software FOBA MarkUS Software for Laser Marking and Engraving Software for laser marking and engraving with vision Programs and tools for...

Open the catalog to page 2

Vision, Workflow and Fixtureless Marking with MOSAIC™ The camera systems IMP and Point & Shoot use vision through the lens and the galvo mirrors to ensure ultimate precision, flexibility, simplicity and repeatability. With our full-field-imaging feature MOSAIC™, cost of production are drastically reduced. Laser-integrated unique vision tools for precision, flexibility, simplicity and repeatability Vision Systems, MOSAIC™ and HELP (Holistic Enhanced Laser Process) Focused on precision, economy, and marking and engraving quality without compromise With Point & Shoot marking contents are...

Open the catalog to page 3

For precision and repeatability: Innovative vision alignment tools The vision systems IMP (Intelligent Mark Positioning) and Point & Shoot ensure ultimate precision and repeatability. With Point & Shoot marking contents are placed manually directly on a screen image of the product to be marked. This system is perfect for the processing of high-quality work pieces and individual parts. The patented camera system IMP automatically detects work pieces and their positioning, and adjusts the marking/ engraving accordingly. That is why IMP is ideal for automated batch production. It all starts...

Open the catalog to page 4

Datamatrix code validation Best aid for all laser marking applications Software and vision features with added value MarkUS provides the ability to read barcodes. Serial barcodes, as well as 2D codes such as the QR, DataMatrix, GS1 and UDI (Unique Device Identifier) codes, can be read and validated in a fraction of a second after being marked. System Health Monitor With the barcode reading feature, code contents are read and compared to their expected contents. The system will also check marked codes based on features like contrast, uniformity, error correction etc. FOBA's M-Series laser...

Open the catalog to page 5

Scan head specifications P&S = Point and Shoot IMP = Intelligent Mark Positioning CV = Code Validation 1 As long as the part can be marked flat

Open the catalog to page 6

FOBA MarkUS and Vision Technical Data Standard features Interfaces Axis control* Radial segmentation* File support Supported lasers Laser Parameter Expert Rotary banding* Training videos MarkUS Designer, MarkUS Runtime, MarkUS Administrator Support and control of up to 5 axes Marking (texts, logos) on the circumference of cylindrical objects (rings, jewelry; arced, concave, convex). Allows the laser to maintain focus to the surface while marking and minimizing distortion caused by the surface curvature. Note: IMP is not available with this feature. Import functions for the most common file...

Open the catalog to page 7All FOBA Laser Marking + Engraving catalogs and technical brochures

-

Laser purchase infographic

1 Pages

-

Service Packs Overview

4 Pages

-

Product brochure

4 Pages