Catalog excerpts

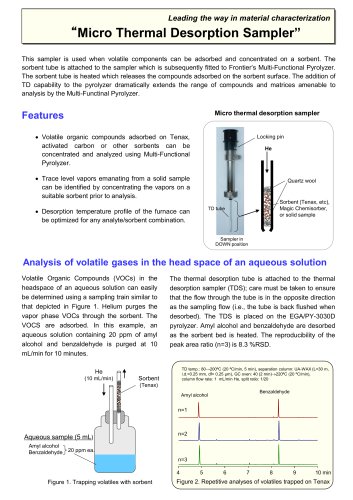

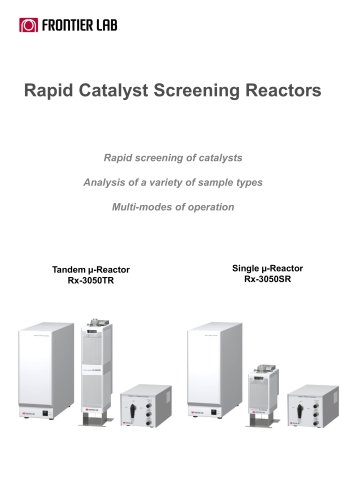

Leading the way in material characterization “Micro Thermal Desorption Sampler” This sampler is used when volatile components can be adsorbed and concentrated on a sorbent. The sorbent tube is attached to the sampler which is subsequently fitted to Frontier’s Multi-Functional Pyrolyzer. The sorbent tube is heated which releases the compounds adsorbed on the sorbent surface. The addition of TD capability to the pyrolyzer dramatically extends the range of compounds and matrices amenable to analysis by the Multi-Functinal Pyrolyzer. Micro thermal desorption sampler Features • Volatile organic compounds adsorbed on Tenax, activated carbon or other sorbents can be concentrated and analyzed using Multi-Functional Pyrolyzer. • Trace level vapors emanating from a solid sample can be identified by concentrating the vapors on a suitable sorbent prior to analysis. Quartz wool Sorbent (Tenax, etc), Magic Chemisorber, or solid sample • Desorption temperature profile of the furnace can be optimized for any analyte/sorbent combination. Sampler in DOWN position Analysis of volatile gases in the head space of an aqueous solution Volatile Organic Compounds (VOCs) in the headspace of an aqueous solution can easily be determined using a sampling train similar to that depicted in Figure 1. Helium purges the vapor phase VOCs through the sorbent. The VOCS are adsorbed. In this example, an aqueous solution containing 20 ppm of amyl alcohol and benzaldehyde is purged at 10 mL/min for 10 minutes. The thermal desorption tube is attached to the thermal desorption sampler (TDS); care must be taken to ensure that the flow through the tube is in the opposite direction as the sampling flow (i.e., the tube is back flushed when desorbed). The TDS is placed on the EGA/PY-3030D pyrolyzer. Amyl alcohol and benzaldehyde are desorbed as the sorbent bed is heated. The reproducibility of the peak area ratio (n=3) is 8.3 %RSD. TD temp.: 80→200ºC (20 ºC/min, 5 min), separation column: UA-WAX (L=30 m, i.d.=0.25 mm, df= 0.25 µm), GC oven: 40 (2 min)→220ºC (20 ºC/min), column flow rate: 1 mL/min He, split ratio: 1/20 Sorbent (Tenax) Amyl alcohol Aqueous sample (5 mL) Amyl alcohol Benzaldehyde Figure 1. Trapping volatiles with sorbent Figure 2. Repetitive analyses of volatile

Open the catalog to page 1

Operational procedure 1. Volatiles are trapped on the sorbent in thermal desorption tube. 2. Attach the thermal desorption tube to the thermal desorption sampler ensuring that the flow is reversed from that used during the sampling period. 3. Attach the sampler to the pyrolyzer. Keep the sampler in the “up” position while the furnace temperature equilibrates at the initial temperature and the system comes to a READY state. Auto-switching of the carrier gas flow path Sampler in UP position TD tube Sampler in DOWN position Nut Carrier gas Sampler base 4. Push the sampler “down” so that the...

Open the catalog to page 2All FRONTIER LAB catalogs and technical brochures

-

MJT-2030E_E

4 Pages

-

MSC_E

1 Pages

-

Micro_Reaction_Sampler_E

2 Pages

-

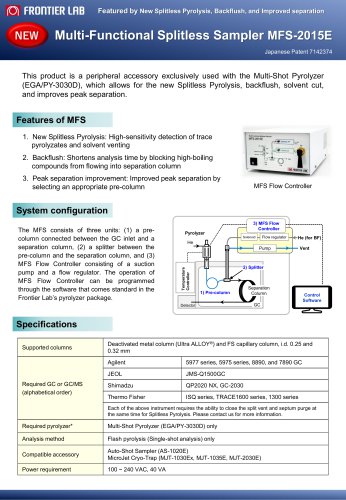

MFS-2015E

2 Pages

-

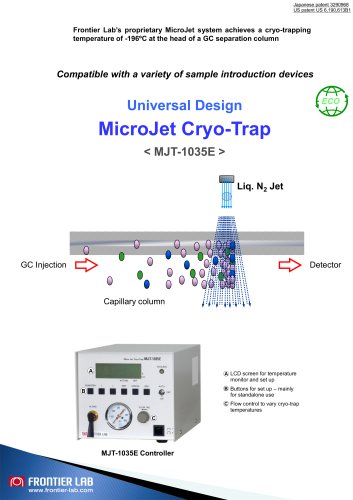

MJT-1035E_E

4 Pages

-

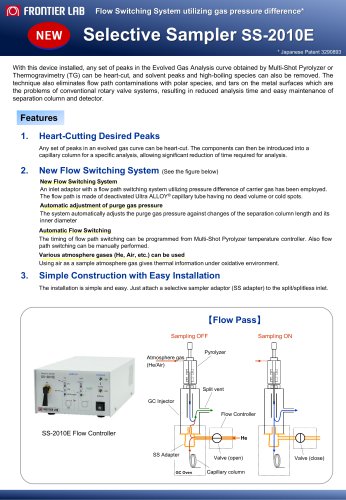

Selective Sampler SS-2010E

2 Pages

-

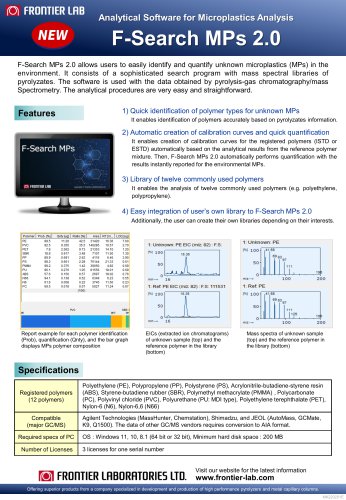

F-Search MPs 2.0

1 Pages

-

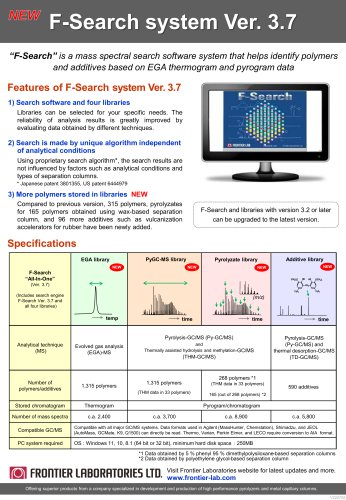

F-Search system Ver. 3.7

1 Pages

-

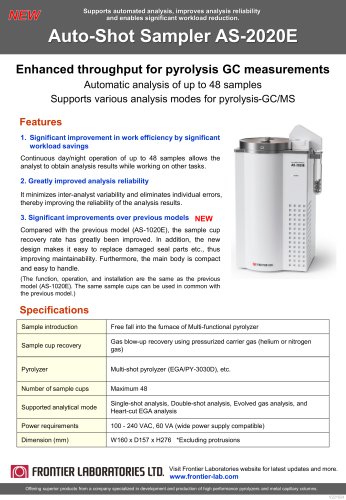

Auto-Shot Sampler AS-2020E

1 Pages

-

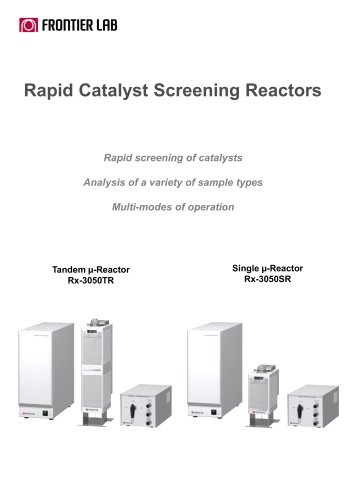

Single µ-Reactor (Rx-3050SR)

8 Pages

-

Tandem µ-Reactor (Rx-3050TR)

8 Pages