Catalog excerpts

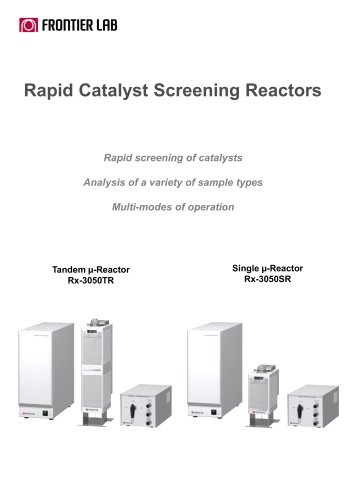

Rapid Catalyst Screening Reactors Rapid screening of catalysts Analysis of a variety of sample types Multi-modes of operation

Open the catalog to page 1

Overview Two accessories, the Selective Sampler and the MicroJet Cryo-Trap, enable the products formed in up to eight thermal zones, to be automatically analyzed. Both reactors are designed to heat and cool rapidly which increase the number of catalysts that can be characterized in a given period of time. Three different reaction gases can be connected to the system so that each catalyst can be evaluated under a variety of reaction conditions. Two types of rapid catalyst screening reactors (Tandem µ-Reactor and Single µ-Reactor) have been developed to facilitate the rapid characterization...

Open the catalog to page 2

Features of the Rapid Catalyst Screening Reactors 1. Internal design of the reactors Sample introduced here. Stainless steel tube Tandem µ-Reactor (deactivated with quartz) 1st Reactor furnace 1st Interface Tandem µ-Reactor consists of two reactors connected in series. The 1st Reactor is used to preheat a gaseous sample, vaporize a liquid sample, or pyrolyze a solid sample. The 1st Reactor operates at a constant temperature. The volatiles exit the 1st Reactor and flow to the 2nd Reactor. A dedicated reaction temperature controller controls the heating and cooling of the reactor. It also has...

Open the catalog to page 3

Features of the Rapid Catalyst Screening Reactor 2. Highly precise temperature control for minimal reactor temperature fluctuations 1st Reactor The thermal profile of the catalyst reaction tube inside the 2nd reactor between 100 and 700ºC is shown in the figure below. The temperature variation within a 40 mm length of the catalyst bed is ±0.1ºC and the maximum temperature deviation is 3ºC at 400ºC. The reactor temperature can be easily calibrated using an external temperature sensor that is inserted into the center of the reactor. 1st Interface heater Reaction gas Reactor Temperature...

Open the catalog to page 4

Features of the Rapid Catalyst Screening Reactor 4. Exchanging the catalyst reaction tube Quick-change catalyst reaction tubes For the Tandem µ-Reactor, remove the 1st Reactor. The reaction tube (located in the 2nd Reactor) can then be easily replaced by lifting the tube from the top of the reactor. Tandem µ-Reactor Single µ-Reactor O-ring Catalyst reaction tube (Quartz) When using the Single µ-Reactor, simply unscrew the liquid sampler, and lift the reaction tube as shown in the figure on the far right. Liquid Sampler (syringe injection) Packing the catalyst reaction tube O-ring The...

Open the catalog to page 5

Control software Reactor temp. settings Setting analytical conditions Operation status The left side of the control software screen is used to set up the temperatures, rates and times for the reactors, interfaces and accessory devices such as the MicroJet Cryo-Trap (MJT) and Selective Sampler (SS). The right side of the control software screen displays operation status such as set points, elapsed time and actual temperatures realtime. Note the colored graphical icons at the top of these screens. Simply clicking on these toggles the screen view for each of three temperature analysis modes....

Open the catalog to page 6

Application 1: Catalytic conversion of ethanol to ethylene Online – MS analysis Separation analysis “ Linear temp. mode ” Ethanol (m/z 45) Diethylether (m/z 74) Ethylene (m/z 28) Diethyl ether Peak Area Peak intensity Peak intensity Diethyl ether Reaction temp. vs. Peak area Catalytic reaction products were monitored as the reaction temperature was raised at a constant rate. The amount of ethanol sharply dropped when the temperature reached 280ºC, while the amount of diethyl ether increased. Also, the formation of ethylene and water is observed. These are the plots of the peak areas...

Open the catalog to page 7

Specifications Tandem µ-Reactor Rx-3050TR 1st Reactor Temperature control range 40 to 700 ºC (1 ºC step, stainless steel flow path, cooling gas) 40 to 900 ºC (1 ºC step, quartz flow path, cooling gas) Cylindrical ceramic heater (400 W) Flow path material Stainless steel (surface deactivated with a bonded silica thin film). Interface (ITF) temperature range 40 to 400 ºC (1 ºC step, constant temp. control) Three gas lines manual valve switching, Gas flow rate control (Max 100 mL/min, 1 MPa) Same as left specification Same as left specification Single µ-Reactor Temperature control range Same...

Open the catalog to page 8All FRONTIER LAB catalogs and technical brochures

-

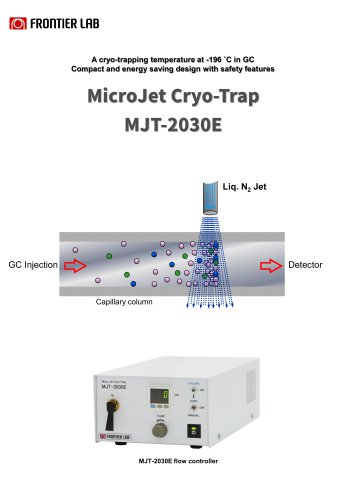

MJT-2030E_E

4 Pages

-

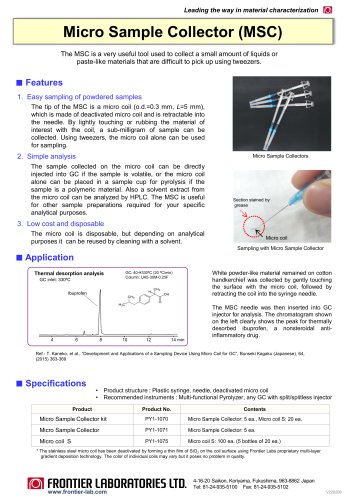

MSC_E

1 Pages

-

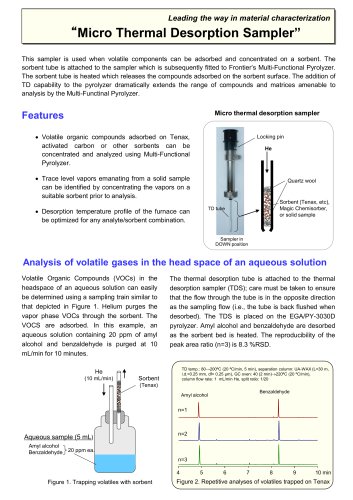

MicroTD_Sampler_E

2 Pages

-

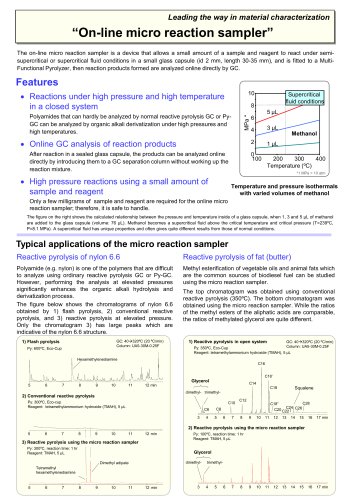

Micro_Reaction_Sampler_E

2 Pages

-

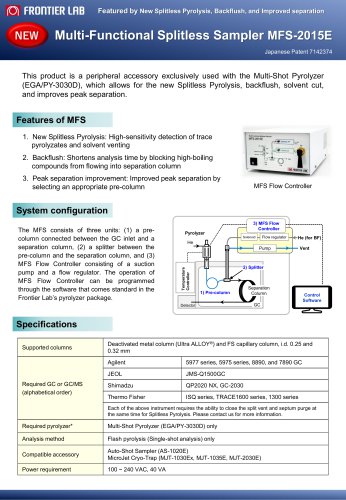

MFS-2015E

2 Pages

-

MJT-1035E_E

4 Pages

-

Selective Sampler SS-2010E

2 Pages

-

F-Search MPs 2.0

1 Pages

-

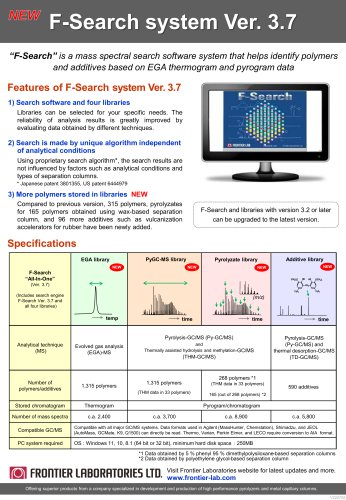

F-Search system Ver. 3.7

1 Pages

-

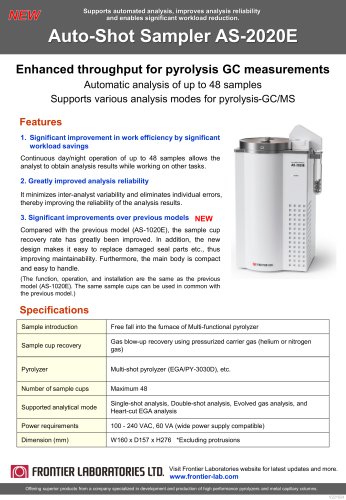

Auto-Shot Sampler AS-2020E

1 Pages

-

Single µ-Reactor (Rx-3050SR)

8 Pages

-

Tandem µ-Reactor (Rx-3050TR)

8 Pages