Catalog excerpts

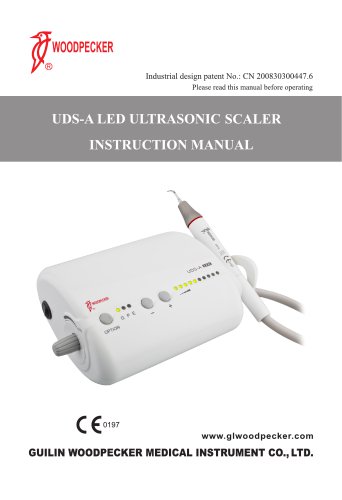

1. The installation and components of equipment 1.1 Instruction Guilin Woodpecker Medical Instrument Co., Ltd. is a professional manufacturer in researching, developing and producing ultrasonic scalers. The product is mainly used for teeth cleaning and is also an indispensable equipment for teeth disease prevention and treatment. The product UDS-A LED ultrasonic scaler has scaling, perio and endo functions. It contains the following features: 1.1.1 Optical handpiece, more convenient for clinical operation. 1.1.2 Automatic frequency tracking ensures that the machine always works on the best...

Open the catalog to page 3

1.3.17 Degree of protection against harmful ingress of water: Ordinary equipment , Protection degree against water (used on the foot switch): IPX1 1.3.18 Degree of safety of application in the presence of a Flammable Anesthetic Mixture with air or with Oxygen or Nitrous Oxide: Equipment is not suitable for being used in the presence of a flammable anesthetic mixture with air or with oxygen or nitrous oxide 1.4 Installation of the main components 1.4.1 Sketch map for installation and connection a) The components of the equipment are showed in picture 1(a,b) picture 1(b) b) Sketch map for...

Open the catalog to page 4

picture 2 c) Sketch map for connection of water supply system are showed in picture3. piture 3 d) Sketch map for connection of detachable handpiece. are showed in picture 4. 3

Open the catalog to page 5

picture 4 e) Sketch map for how to install tip and endochuck with wrench are showed in picture 5. picture 5 2. Product function and operation 2.1 Scaling function 4

Open the catalog to page 6

2.1.1 Operation a) Open the packing box, make sure that all the parts and accessories are complete according to the packing list. Take the main unit out of the box and put it on a stable plane. b) Turn the water control knob to the max based on symbol as shown as 3.5.2 [note l]. c) Insert the plug of the foot knob to its socket (picture 2). d) Connect one end of the water pipe to the water entrance, and the other end to the pure water source (picture 3). e) Screw the scaling tip tightly to handpiece by torque wrench, then connect the handpiece and the connector of cable correctly. f) Insert...

Open the catalog to page 7

the pole with alcohol termly. b) Decorative ring: can be disassembled and cleaned with alcohol regularly, can be autoclaved under the high temperature and pressure. c) Handpiece: The main part of the whole handpiece, can be autoclaved under the high temperature and pressure. d) The connector of the cable: Connect the handpiece with the water source and power supply of the main unit. e) LED lamp、Light pipe: Clean them with purified water and sterilize them under the high temperature of 134°Cand high pressure of 0.22Mpa. Notice: Keep the connector dry. 2.1.3 Torque wrench instruction (showed...

Open the catalog to page 8

a) When fixing endochuck, it must be screwed down. b) The screw cap on the endochuck must be screwed down. c) Don’t press it too hard when the endo file is in the root canal. d) Don’t step on the foot switch until the endo files is in the root canal. e) The power range is supposed from 1st to 5th grade. 3. Maintenance 3.1 Troubleshooting Fault Possible The plug is in loose or The scaling tip doesn’t wrong contact. vibrate and there is no Solutions Connect the power plug well. The foot switch is in loose. Connect the switch well. water flowing out when The fuse of transformer is The fuse in...

Open the catalog to page 9

The water control switch is Turn on the water control The scaling tip vibrates off. electric-magnetic valve. switch. The water system is Clean the water line by multi-function syringe [note 2]. There is still water electric-magnetic valve. power is off. The handpiece generates The water control switch is Turn the water control heat. switch to a higher grade [note 2]. The amount of spouting The water pressure is not Make the water pressure high enough. The water line is blocked. Clean the water pipe by multi-function syringe [note2]. The tip hasn't been screwed Screw the tip on the on to the...

Open the catalog to page 10

There is water seeping from the coupling The waterproof "O" ring is Change a new "O" ring. between the handpiece damaged. and the cable. The endo file doesn’t Poor contact Contact tightly Something wrong with LED light LED light don't work There is noise coming from the endochuck If the problem still can't be solved, please contact with local dealer or manufacturere. 3.2 Notice a) [Note l] Turn water control knob can adjust the water volume according to the symbol. b) [Note 2] Clean the water pipe with the multi-function syringe of the dental unit (as showed in picture 6):

Open the catalog to page 11

① Cut the water pipe at a distance of 10cm to 20cm from the water entrance. ② Turn on the electricity and get through the electricity. ③ Connect the multi-function syringe of dental unit to the water pipe. ④ Disassemble the tip or handpiece. ⑤ Step on the foot switch. ⑥ Turn on the switch of the multi-function syringe, press the water into the machine and the impurity blocked in the water pipe can be eliminated. c) [Note 3] If the scaling tip has been screwed on tightly and there is fine spray too, the following phenomena show that the scaling tip is damaged: ① The vibrating intensity and...

Open the catalog to page 12

The post-operative treatment must be carried out immediately, no later than 30 minutes after the completion of the operation. The steps are as follows: 1. Let the Ultrasonic Scaler works for 20-30 seconds at maximum water volume to flush the handpiece and tip; 2. Remove the handpiece from the Ultrasonic scaler, and rinse away the dirt on the surface of product with pure water (or distilled water/deionized water); 3. Dry the product with a clean, soft cloth and place it in a clean tray. Notes a) The water used here must be pure water, distilled water or deionized water. 4.2 Preparation...

Open the catalog to page 13

15883. For the specific procedure, please refer to the automated disinfection section in the next section “Disinfection”. Notes a) The cleaning agent does not have to be pure water. It can be distilled water, deionized water or multi-enzyme. But please ensure that the selected cleaning agent is compatible with the product. b) In washing stage, the water temperature should not exceed 45 °C, otherwise the protein will solidify and it would be difficult to remove. c) After cleaning, the chemical residue should be less than 10mg / L. 4.4 Disinfection Disinfection must be performed no later than...

Open the catalog to page 14All Guilin Woodpecker Medical Instrument Co. catalogs and technical brochures

-

CATALOGUE

56 Pages

-

UDS-B

19 Pages

-

iScan

29 Pages

-

dental instrument catalogue

8 Pages