Catalog excerpts

1 The installation and components of equipment 1.1 Instruction Guilin Woodpecker Medical Instrument Co., Ltd. is a professional manufacturer in researching, developing and producing ultrasonic scaler. The product is mainly used for teeth cleaning and also an indispensable equipment for teeth disease prevention and treatment. The product UDS-B ultrasonic scaler has scaling function. It contains the following features: 1.1.1 Automatic frequency tracking ensures that the machine always works on the best frequency and more steadily. 1.1.2 Digitally controlled, easy operation and more efficient...

Open the catalog to page 3

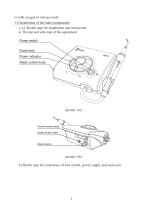

or with oxygen or nitrous oxide. 1.4 Installation of the main components 1.4.1 Sketch map for installation and connection a) The top and side map of the equipment picture 1(b) b) Sketch map for connection of foot switch, power supply and main unit.

Open the catalog to page 4

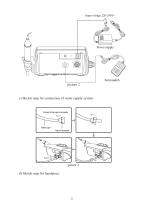

c) Sketch map for connection of water supply system. piture 3 d) Sketch map for handpiece.

Open the catalog to page 5

picture 4 e) Sketch map for installing tip with wrench. picture 5 2. Product function and usage 2.1 Scaling function 2.2 Usage 2.2.1 Open the packing box, make sure that all the parts and accessories are complete according to the packing list. Take the main unit out of the box and put it on a stable plane. 2.2.2 Turn the water control knob to the max based on symbol as shown in 3.4.2 [note l]. 2.2.3 Insert the plug of the foot switch to its socket (picture 2). 2.2.4 Connect one end of the water pipe to the water entrance, and the other end to the pure water source (picture 3). 2.2.5 Insert...

Open the catalog to page 6

2.2.7 Select a suitable scaling tip as you need, screw it on the handpiece tightly by the wrench (picture 5). 2.2.8 The normal frequency is extremely high. Under the normal working state of the scaling tip, a light touch and a certain to-and-fro motion will eliminate the tartar without heating. Overexertion and long-time lingering are forbidden. 2.2.9 Vibrating intensity: adjust the vibration intensity as you need, generally turn the knob to the middle grade. According to patients' different sensitivity and the rigidity of the gingival tartar, adjust the vibration intensity during the...

Open the catalog to page 7

If the problem still can’t be solved, please contact with local dealer or manufacturer. 3.2 Notice [Note l] Turn the water control knob toward direction of symbol till not be able to turn any more, it comes to the min; on the contrary direction, the water volume 6

Open the catalog to page 8

increases step by step till not be able to turn anymore. [Note 2] Clean the water pipe with the multi-function syringe of the dental unit (as showed in picture 6): ① Cut the water pipe at a distance of 10cm~20cm from the water entrance. ② Turn on the electricity and get through to the power. ③ Connect the multi-function syringe of dental unit to the water pipe. ④ Disassemble the tip or handpiece. ⑤ Step on the foot switch. ⑥ Turn on the switch of the multi-function syringe, press the water into the machine and the impurity blocked in the water pipe can be eliminated. [Note 3] If the scaling...

Open the catalog to page 9

4.1 Initial processing 4.1.1 Processing principles It is only possible to carry out effective sterilization after the completion of effective cleaning and disinfection. Please ensure that, as part of your responsibility for the sterility of products during use, only sufficiently validated equipment and product-specific procedures are used for cleaning/disinfection and sterilization, and that the validated parameters are adhered to during every cycle. Please also observe the applicable legal requirements in your country as well as the hygiene regulations of the hospital or clinic,especially...

Open the catalog to page 10

agent is compatible with the product. b) In washing stage, the water temperature should not exceed 45 °C, otherwise the protein will solidify and it would be difficult to remove. c) After cleaning, the chemical residue should be less than 10mg / L. 4.3Disinfection Disinfection must be performed no later than 2 hours after the cleaning phase. Automated disinfection is preferred if conditions permit. 4.3.1 Automated disinfection-Washer-disinfector •The washer-disinfector is proved to be valid by CE certification in accordance with EN ISO 15883. •Use high temperature disinfection function. The...

Open the catalog to page 11

A0 ≥ 600 (d3) For the disinfection here,the temperature is 93 ° C, the time is 2.5 min, and A0>3000 e) Only distilled or deionized water with a small amount of microorganisms (<10 cfu/ml) can be used for all rinsing steps. (For example, pure water that is in accordance with the European Pharmacopoeia or the United States Pharmacopoeia). f) After cleaning, the chemical residue should be less than 10mg / L. g)The air used for drying must be filtered by HEPA. h) Regularly repair and inspect the disinfector. 4.4Drying If your cleaning and disinfection process does not have an automatic drying...

Open the catalog to page 12

b) It can withstand high temperature of 138 °C and has sufficient steam permeability; c) The packaging environment and related tools must be cleaned regularly to ensure cleanliness and prevent the introduction of contaminants; d) Avoid contact with parts of different metals when packaging. 4.7Sterilization Use only the following steam sterilization procedures (fractional pre-vacuum procedure*) for sterilization, and other sterilization procedures are prohibited: 1. The steam sterilizer complies with EN13060 or is certified according to EN 285 to comply with EN ISO 17665; 2. The highest...

Open the catalog to page 13

a)The storage environment should be clean and must be disinfected regularly; b) Product storage must be batched and marked and recorded. 4.9Transportation 1.Prevent excessive shock and vibration during transportation, and handle with care; 2. It should not be mixed with dangerous goodsduring transportation. 3. Avoid exposure to sun or rain or snow during transportation. The cleaning and disinfection of main unit and handpiece are as follows. 1 Pre-Op processing Before each use, the handpiece and main unitmust be cleaned and disinfected. The specific steps are as follows: 1.1 Manual...

Open the catalog to page 14All Guilin Woodpecker Medical Instrument Co. catalogs and technical brochures

-

CATALOGUE

56 Pages

-

UDS-A

26 Pages

-

iScan

29 Pages

-

dental instrument catalogue

8 Pages