Catalog excerpts

hm 850 DC-V hm 880 DC-V / ROTARY SEALERS WITH PRINTER (VALIDATABLE PROCESS IN ACCORDANCE WITH ISO 11607-2)

Open the catalog to page 1

GENERATION PRO THE HM 850 DC-V AND HM 880 DC-V GENERATION PRO ROTARY SEALING DEVICES WITH INTEGRATED PRINTER ARE THE ANSWER TO PROFESSIONAL REQUIREMENTS IN HOSPITALS AND THE MEDICAL INDUSTRY. THE PROCESS IS VALIDATABLE IN ACCORDANCE WITH ISO 11607-2. ROBUST AND BUILT FOR MAXIMUM COMFORT AS USUAL, THE DESIGN EMPHASIZES THE INTRINSIC VALUES OF THESE DEVICES: MAXIMUM PERFORMANCE AND SPEED, AUTOMATIC MONITORING OF THE CRITICAL PROCESS PARAMETERS SEAMLESS INTEGRATION INTO TRACKING SYSTEMS AND VERY EASY TO USE HANDLING THANKS TO THE SUCCESSFUL hawo IntelligentScan TECHNOLOGY (HM 880 DC-V) MAKES...

Open the catalog to page 2

THE PRO CLASS. The validatable rotary sealers are used for the automatic closing of sealable pouches and reels (Sterile Barrier Systems SBS) in hospitals (CSSD) and the medical industry. Our successful classic model hm 850 DC-V was updated and changed to the current design. The hm 880 DC-V includes all hawo top technologies and sets the benchmark in its class. INTEGRATED PRINTER WITH FontMatic (hm 880 DC-V). The hm 850 DC-V and hm 880 DC-V can print all normatively requested information directly onto the packaging during the sealing process (symbols according to EN 980). Thanks to the...

Open the catalog to page 3

RANGE OF USE AND CERTIFICATIONS Especially suitable for use in hospital and medical industry hospital and medical industry POWER SUPPLY AND MECHANICAL DATA Mains connection / mains frequency Dimensions w x d x h (incl. infeed section) Casing cover Stainless steel AISI 304 Stainless steel AISI 304 Sealing system Sealing distance from edge Seal seam width Distance to medical product (DIN 58953-7) Device protection (insert guard) Reverse feed All sealable gussetted pouches and reels according ISO 11607-1 (e.g. medical grade paper, Tyvek®, nonwoven, etc.) SEALING MATERIALS ELECTRONIC FEATURES...

Open the catalog to page 4

SAFE PACKAGING. The correct reprocessing process of medical devices consists of the steps of washing & disinfection, packaging and sterilisation. The instruments can only be called sterilised when they are packaged PACKAGING before the sterilisation. The single-use (!) packaging, made from laminated poly film and a porous material (Tyvek® or medical grade paper) is permeable for the sterilisation medium (e. g. steam, plasma, Formaldehyde FO or Ethylenoxide ETO), but not for bacteria or microorganisms. Only by following this reprocessing sequence (see illustration left) and by using...

Open the catalog to page 5

PROCESS DOCUMENTATION. Following the requirements set out in ISO 11607-2, the routine monitoring and documentation of the process parameters can be carried out with the help of a USB stick and the hawo ht 180 PT USB storage unit. The process protocols can then be called up, digitally signed and archived on a PC. Seal Check med | Seal Check HDPE | hawo InkTest FOR ROUTINE MONITORING OF THE SEALING SEAMS. hawo offers two testing systems for the routine testing of the sealing seam as well as to carry out an Operational Qualification (OQ) and Performance Qualification (PQ) during the validation...

Open the catalog to page 6All Hawo catalogs and technical brochures

-

hpl 300 BMS / 500 BMS

2 Pages

-

hv 300 K-V MediVac

6 Pages

-

Bowie & Dick-Test

2 Pages

-

hm 950 DC-V/VI NanoPak

6 Pages

-

hm 780 DC-V

6 Pages

-

hm 780 DC

6 Pages

-

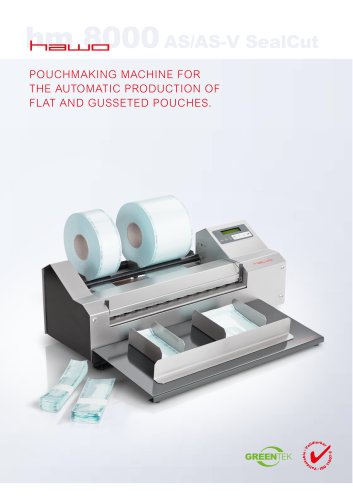

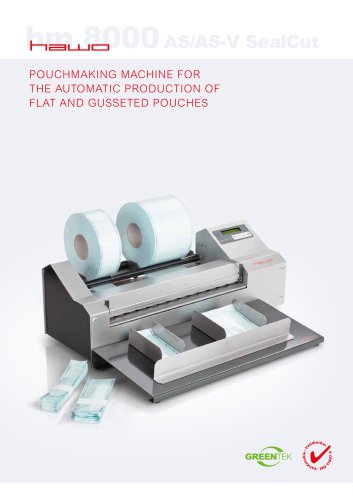

hm 8000 AS / AS-V SealCut

6 Pages

-

hm 460 AS-V / hm 660 AS-V

4 Pages

-

hm 450 AS-8 / hm 630 AS-8

2 Pages

-

hm 300 BMS / hm 500 BMS

2 Pages

-

hpl 3000 DC-V

8 Pages

-

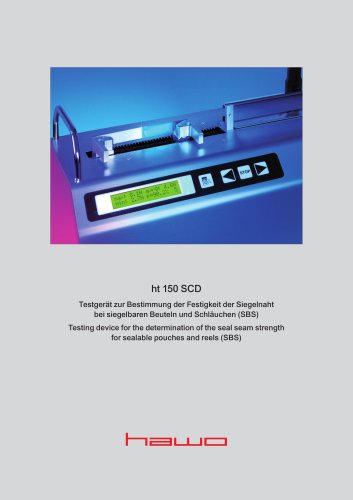

ht 150 SCD

4 Pages

-

hawo viú-2

2 Pages

-

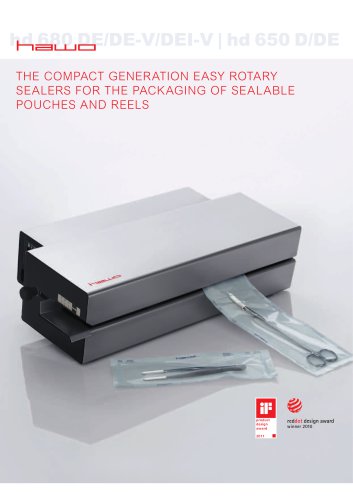

hd 680 DE

4 Pages

-

hm RS

2 Pages

-

hm 300 BMS?/ 500 BM

2 Pages

-

hm 460 AS-V/hm 660 AS-V

4 Pages

-

hm 8000 AS/AS-V SealCut

6 Pages