Catalog excerpts

ua est q high e y. er th ienc e of f ef fic W cost and Silver-Anodes Anode material with a homogeneous, fine-grain microstructure at the highest level of purity Achieve the highest quality and cost Anode material produced by continuous efficiency with your galvanized silvering casting shows a homogeneous fine-grain when you use the highest-caliber silver microstructure at the highest level of purity. anodes from Heimerle + Meule, Germany’s This is guaranteed by thorough application oldest gold and silver refinery. Your benefits: • Homogeneous dissolution avoids separation rates • Excellent adhesion • Manufacturing of highly conductive layers • High purity level of anodes at a minimum of 99.97% Ag • Even separation process Heimerle + Meule GmbH Gold and silver refinery Dennigstrasse 16 · 75179 Pforzheim · Germany T +49.7231.940 0 · F +49.7231.940 2199 info@heimerle-meule.com www.heimerle-meule.com · shop.heimerle-meule.eu A POSSEHL GROUP company technique jewellery dental floating particles High silver availability means high

Open the catalog to page 1

Take advantage of the benefits of coating with silver anode pieces: Raw anodes (continuously cast, cut) Rolled anodes (rolled, annealed) Thickness: 15 mm (edge bead), 10 mm (web thickness), width: 76 mm Anode pieces • Large anode surface areas offer high silver availability, resulting in high separation rates • The highest process consistency is guaranteed by possible post-dosing of spent silver quantity • Higher output results in less anode slime compared to granules • The production of anodes using continuous casting results in homogeneous quality at the highest level of purity • No need...

Open the catalog to page 2All Heimerle + Meule catalogs and technical brochures

-

PVD

2 Pages

-

Targets

2 Pages

-

Collector rings

2 Pages

-

Copper/silver

2 Pages

-

General Brochure

25 Pages

-

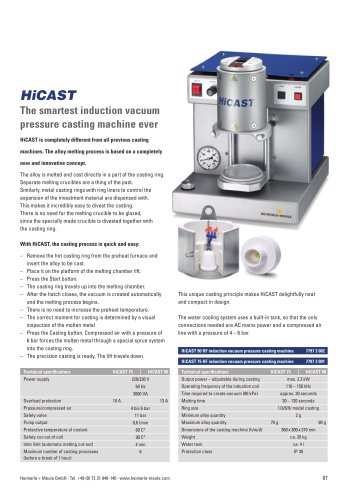

HiCAST

1 Pages

-

PLATINAmat

1 Pages