Catalog excerpts

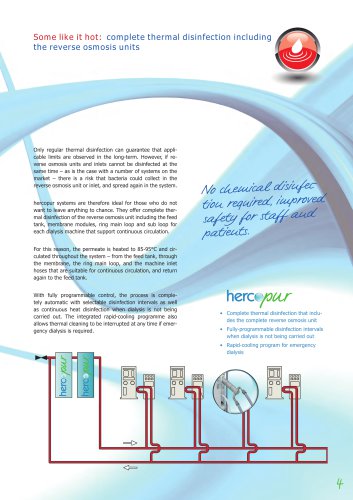

Some like it hot: complete thermal disinfection including the reverse osmosis units Only regular thermal disinfection can guarantee that applicable limits are observed in the long-term. However, if reverse osmosis units and inlets cannot be disinfected at the same time – as is the case with a number of systems on the market – there is a risk that bacteria could collect in the reverse osmosis unit or inlet, and spread again in the system. hercopur systems are therefore ideal for those who do not want to leave anything to chance. They offer complete thermal disinfection of the reverse osmosis unit including the feed tank, membrane modules, ring main loop and sub loop for each dialysis machine that support continuous circulation. No chemical disinfecd tion required, improve safety for staff and patients. For this reason, the permeate is heated to 85-95°C and circulated throughout the system – from the feed tank, through the membrane, the ring main loop, and the machine inlet hoses that are suitable for continuous circulation, and return again to the feed tank. With fully programmable control, the process is completely automatic with selectable disinfection intervals as well as continuous heat disinfection when dialysis is not being carried out. The integrated rapid-cooling programme also allows thermal cleaning to be interrupted at any time if emergency dialysis is required. • Complete thermal disinfection that includes the complete reverse osmosis unit • Fully-programmable disinfection intervals when dialysis is not being carried out • Rapid-cooling program for emergency dialysis

Open the catalog to page 1All Herco Wassertechnik GmbH catalogs and technical brochures

-

Simplex bed head media panel

1 Pages

-

Compact RO - HP 70

2 Pages