Website:

Hosokawa Micron

Website:

Hosokawa Micron

Group: Hosokawa Micron

Catalog excerpts

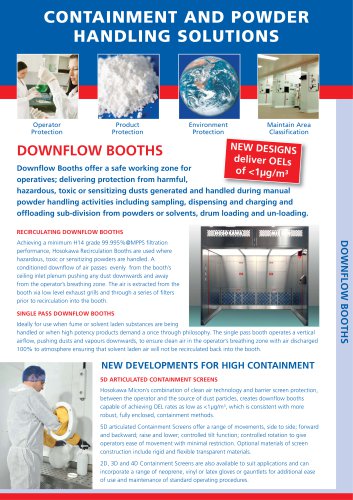

CONTAINMENT AND POWDER HANDLING SOLUTIONS Operator Protection Product Protection Environment Protection DOWNFLOW BOOTHS Maintain Area Classification NEW DESIGNS deliver OELs of <1µg/m3 Downflow Booths offer a safe working zone for operatives; delivering protection from harmful, hazardous, toxic or sensitizing dusts generated and handled during manual powder handling activities including sampling, dispensing and charging and offloading sub-division from powders or solvents, drum loading and un-loading. RECIRCULATING DOWNFLOW BOOTHS SINGLE PASS DOWNFLOW BOOTHS Ideally for use when fume or solvent laden substances are being handled or when high potency products demand a once through philosophy. The single pass booth operates a vertical airflow, pushing dusts and vapours downwards, to ensure clean air in the operator’s breathing zone with air discharged 100% to atmosphere ensuring that solvent laden air will not be recirculated back into the booth. NEW DEVELOPMENTS FOR HIGH CONTAINMENT 5D ARTICULATED CONTAINMENT SCREENS Hosokawa Micron’s combination of clean air technology and barrier screen protection, between the operator and the source of dust particles, creates downflow booths capable of achieving OEL rates as low as <1µg/m3, which is consistent with more robust, fully enclosed, containment methods. 5D articulated Containment Screens offer a range of movements, side to side; forward and backward; raise and lower; controlled tilt function; controlled rotation to give operators ease of movement with minimal restriction. Optional materials of screen construction include rigid and flexible transparent materials. 2D, 3D and 4D Containment Screens are also available to suit applications and can incorporate a range of neoprene, vinyl or latex gloves or gauntlets for additional ease of use and maintenance of standard operating procedures. DOWNFLOW BOOTHS Achieving a minimum H14 grade 99.995%@MPPS filtration performance, Hosokawa Recirculation Booths are used where hazardous, toxic or sensitizing powders are handled. A conditioned downflow of air passes evenly from the booth’s ceiling inlet plenum pushing any dust downwards and away from the operator’s breathing zone. The air is extracted from the booth via low level exhaust grills and through a series of filters prior to recirculation into the

Open the catalog to page 1

CONTAINMENT AND POWDER HANDLING SOLUTIONS BETTER BY DESIGN Hosokawa Micron Ltd can offer a range of standard and bespoke downflow booth options to suit individual requirements in operator protection, product protection, processing activities to be undertaken and environmental and energy issues. Specialists in ergonomic design and integration of processing or packing equipment, Hosokawa Micron is able to design and build the most operator friendly and efficient systems available. Contained Powder Mill Semi-Automatic Drum Filling Booth Suite with Automated Sliding Glass Doors Laminar Flow...

Open the catalog to page 2All Hosokawa Micron catalogs and technical brochures

-

Angle Disintegrator

2 Pages