Website:

Hosokawa Micron

Website:

Hosokawa Micron

Group: Hosokawa Micron

Catalog excerpts

CONTAINMENT TECHNOLOGY & INTEGRATED SOLUTIONS HOSOKAWA MICRON LI PROCESS TECHNOLOGIES FOR TOMORROWsm

Open the catalog to page 1

Hosokawa Micron Ltd is a leading pioneer in the development of containment technologies Innovative containment solutions from the experts in powder and particle processing. Delivering Operator Exposure Levels down to 10ng/m3 and Operator Exposure Band 6. A single source supply of powder processing equipment and containment solutions. Delivering integrated and bespoke solutions which exceed expectations. Working in close partnership with our customers, worldwide. Customised solutions to meet your specific contained processing requirements - no matter how complex or simple.

Open the catalog to page 2

Downflow Booths CUSTOMISED -■ \£. , CONTAINED \ PROCESSING SOLUTIONS Laminar Flow Booths Mobile Isolators Filling and Weighing PAGE 7

Open the catalog to page 3

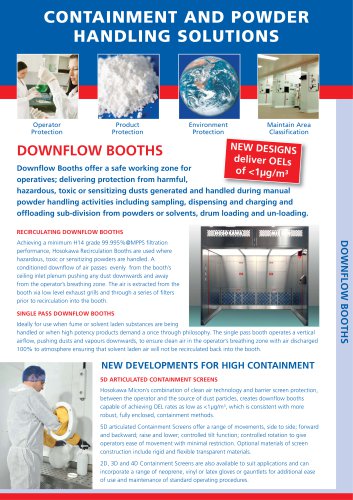

Downflow Booths Downflow booths offer a safe working zone for the protection of operators from the harmful particulates generated during manual handling activities including sampling, dispensing, sub-division, charging and offloading powders or solvents. Hosokawa Micron can offer an extensive range of standard and bespoke downflow booth solutions; with or without integrated equipment. Design Advantages • Guaranteed operator exposure levels of <100|jg/m3 (task duration), can be improved with the use of flexible or rigid high containment screens to 10|jg/m3 (task duration) • Flexible, modular...

Open the catalog to page 4

Design Advantages • 3D modelling and full size ergonomic mock ups • Manufactured to meet cGMP, FDA, EMA guidelines • Designed to accommodate Hosokawa Micron or 3rd party equipment Integrated Engineering Hosokawa powder processing equipment can be re-designed for installation inside Gloveboxes/ Isolators for a more bespoke processing response and delivering an improved ergonomic solution. Gloveboxes & Isolators In response to the development of increasingly potent and potentially toxic pharmaceutical products and chemicals, Hosokawa Micron has a proven range of standard and bespoke barrier...

Open the catalog to page 5

Laminar Flow Booths The Hosokawa Laminar Flow Booth’s controlled, nonturbulent, filtered airflow means only clean air is in the operator’s breathing zone and particles generated during processing activities are pushed away from the breathing zone. Custom-built or in standard sizes, the ergonomic design of the Hosokawa Laminar Flow Booths allow a wide range of containers to be handled either manually or automatically and are designed for fixed or portable operation or as a standalone workstation. Design Advantages • Complete with integral fan/motor systems, internal lighting, integrated hand...

Open the catalog to page 6

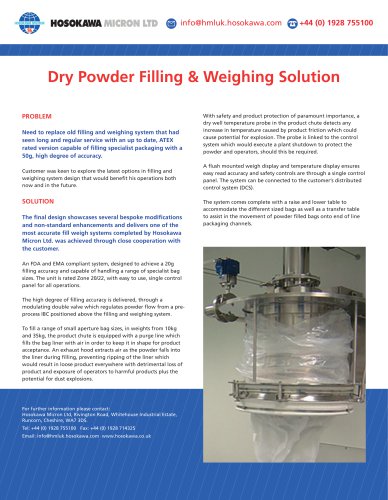

Filling & Weighing Systems Accurate weight controlled filling systems from Hosokawa Micron maintain the highest standards of hygiene, dust control and product integrity. They deliver accurate, stable and repeatable weight readings. Available in standard or bespoke designs our filling and weighing systems can be designed for use in hazardous areas. They incorporate interchangeable, Stott design inflatable packing heads and integrated weigh platforms to provide automatic control of bulk and dribble filling modes. Design Advantages • Designed for flexible filling of a range of container sizes...

Open the catalog to page 7

Service, Validation, Upgrades Having selected the best equipment on the market it makes sense to protect your investment by inviting Hosokawa Micron service engineers to share their full range of expertise with your maintenance engineers. Together you can ensure your containment, processing and ancillary equipment is running at optimum efficiency and meeting critical performance standards. Testing and Validation To ensure your containment equipment operates correctly and meets critical standards our trained engineers carry out a full range of testing and validation procedures including: •...

Open the catalog to page 8All Hosokawa Micron catalogs and technical brochures

-

Angle Disintegrator

2 Pages