Website:

Hosokawa Micron

Website:

Hosokawa Micron

Group: Hosokawa Micron

Catalog excerpts

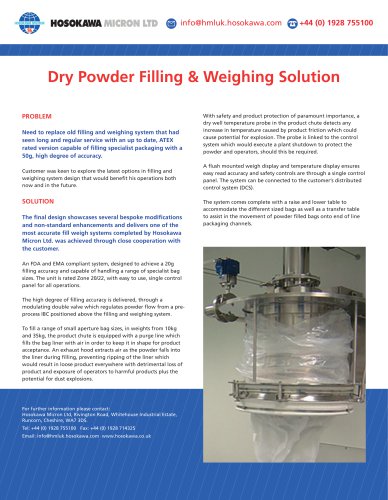

Dry Powder Filling & Weighing Solution PROBLEM Need to replace old filling and weighing system that had seen long and regular service with an up to date, ATEX rated version capable of filling specialist packaging with a 50g, high degree of accuracy. Customer was keen to explore the latest options in filling and weighing system design that would benefit his operations both now and in the future. SOLUTION The final design showcases several bespoke modifications and non-standard enhancements and delivers one of the most accurate fill weigh systems completed by Hosokawa Micron Ltd. was achieved through close cooperation with the customer. An FDA and EMA compliant system, designed to achieve a 20g filling accuracy and capable of handling a range of specialist bag sizes. The unit is rated Zone 20/22, with easy to use, single control panel for all operations. The high degree of filling accuracy is delivered, through a modulating double valve which regulates powder flow from a preprocess IBC positioned above the filling and weighing system. To fill a range of small aperture bag sizes, in weights from 10kg and 35kg, the product chute is equipped with a purge line which fills the bag liner with air in order to keep it in shape for product acceptance. An exhaust hood extracts air as the powder falls into the liner during filling, preventing ripping of the liner which would result in loose product everywhere with detrimental loss of product and exposure of operators to harmful products plus the potential for dust explosions. For further information please contact: Hosokawa Micron Ltd, Rivington Road, Whitehouse Industrial Estate, Runcorn, Cheshire, WA7 3DS. Tel: +44 (0) 1928 755100 Fax: +44 (0) 1928 714325 Email: info@hmluk.hosokawa.com www.hosokawa.co.uk With safety and product protection of paramount importance, a dry well temperature probe in the product chute detects any increase in temperature caused by product friction which could cause potential for explosion. The probe is linked to the control system which would execute a plant shutdown to protect the powder and operators, should this be required. A flush mounted weigh display and temperature display ensures easy read accuracy and safety controls are through a single control panel. The system can be connected to the customer’s distributed control system (DCS). The system comes complete with a raise and lower table to accommodate the different sized bags as well as a transfer table to assist in the movement of powder filled bags onto

Open the catalog to page 1All Hosokawa Micron catalogs and technical brochures

-

Angle Disintegrator

2 Pages