Catalog excerpts

Check Valve I Application A check valve, or non return valve, is a valve that prevents the fluid from flowing backwards and ensures that it flows in only one direction. It can be used to prevent the loss of prime of the pump and water hammer. It is used in the food-processing, cosmetics, pharmaceutical and chemical industries as well as in the beverage, wine and oil production. I Operating principle The check valve opens when the pressure of the fluid exceeds the pressure exerted by the spring. When the two pressures are compensated, the valve closes. A higher counterpressure will ensure the valve closes. When there are two pumps operating alternately, the check valves are installed at the outlet of each pump to prevent the backflow when the pump is stopped. The obturation disc is provided with a perforation for a minimal circulation flow to avoid water stagnancy. I Design and features Available sizes: DN 25/1" to 100/4". Easy assembly/disassembly with the clamp. Reduced size design. Connections: Male DIN 11851. I Materials Parts in contact with the product Other stainless steel parts Spring Gasket Internal surface finish External surface finish AISI 316L (1.4404) AISI 304 (1.4301) AISI 302 (1.4319) EPDM according to FDA 177.2600 Ra ≤ 0,8 μm Machined (turned) I Options Option: a small perforation provides for a minimal circulation flow Gaskets: NBR, FPM or PTFE. Connections: Weld DIN 11850, Weld OD ASME BPE, Clamp DN 32676, Clamp OD ASME BPE, Clamp, SMS, RJT, FIL-IDF, etc. Perforation in the obturation disc. ATEX version available.

Open the catalog to page 1

I Technical specifications Sizes DN 25 - DN 100 DN 1" - DN 4" Max.working temperature The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

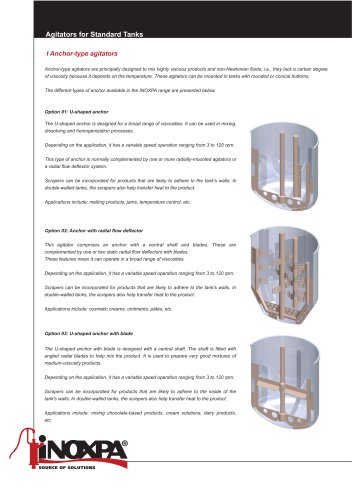

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages