Website:

INOXPA

Website:

INOXPA

Catalog excerpts

High-shear "Multitooth" Mixer Application The 8100X series multitooth mixers are employed in the applications requiring high shear for achieving a thorough emulsification. Until now mills and homogenisers have been used for production of high quality emulsions. The 8100X series mixers achieve similar results and present a more hygienic solution at a lower price. Among the products that can be prepared with this mixer there are mayonnaises, high quality body care products, pharmaceutical and veterinary solutions. I Operating principle The traditional rotor/stator mixers produce point shear at the moment the rotor drives the product through the slots of the stator, and the 8100X series mixers are made up of many concentric rows of teeth. The product enters through the centre of the mixer and moves outward through the radial channels between the rotor/stator teeth. Tolerances are very close, and the tip speed (up to 50 m/s) and the shear rates are very high. I Design and features High shear. Particle size reduction to less than 10 micrometers. Tip speed up to 50 m/s. Sealing system: sanitary single cooled mechanical seal. Adjustment of different tolerances between the rotor and stator. CIP compatible design. Standard connections: Clamp ISO-2852. Assembly with pulleys and belts. Clamp drain port. Motors: IEC B3, IP 55, F class insulation, 3000 rpm. I Materials Parts in contact with the media Other steel parts Seal Gaskets Surface finish AISI 316L AISI 304 C / SiC EPDM electropolished, Ra 0.8

Open the catalog to page 1

Double mechanical seal. Other mechanical seal and gasket materials. Motors with other protections. Speed adjustment: frequency converter or change of relation of pulleys. Control panel. /^Inckrv L SOURCE OF SOLUTIONS The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

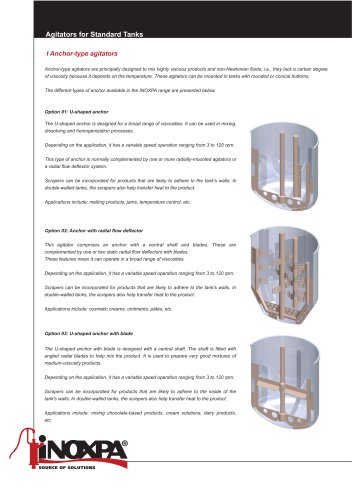

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages