Website:

INOXPA

Website:

INOXPA

Catalog excerpts

Bottom Magnetic Agitator I Application The range of magnetic agitators BMA is a highly hygienic solution for the applications of dispersion, dissolution, homogenization and mixing in the pharmaceutical, biotechnological and food-processing industries. Due to the magnetic coupling they are especially useful because they avoid any possible contact of the product with the atmosphere. I Operating principle When solids or liquids are added into the vortex created by the agitator, they are transferred straight to the rotor. The rotor transforms the axial movement of the medium into a radial acceleration from the centre of the rotor towards the wall of the vessel. The added medium is well distributed ensuring a homogeneous mixing of all the volume. It is strongly advised to assemble the agitator in eccentric position in order to minimize vortex and to avoid the installation of deflectors. I Design and features Magnetic coupling Magnetic coupling. No leakage. Designed for cleaning and sterilization (CIP and SIP). Very low particle generation. Bottom mounted. Excellent for suspensions. Practical when there is no much space at the top of the tank. Easy disassembly: neither lifting device nor special maintenance support required. Autoclavable rotor. I Technical specifications Materials: Parts in contact with the product Bushing O-ring AISI 316L SiC FEP for models up to BMA-225 EPDM for other models

Open the catalog to page 1

I Technical specifications Surface finish Operating limits: Operating temperature Vessel pressure Voltage Protection Maximum mixing volume Maximum working viscosity * For other viscosities, please contact INOXPA. I Options Surface finish: electro polishing. Rotational sensor. ATEX certification. Control panel. Motor Nominal power speed [kw] [rpm] Recommended volume for gentle agitation for water type liquid, viscosity < 10 cP and density 1.000 kg/m3 ‘ For further information, please contact INOXPA. roi luimei iniomiauon, please contact iin The information is for guidance only. We reserve...

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

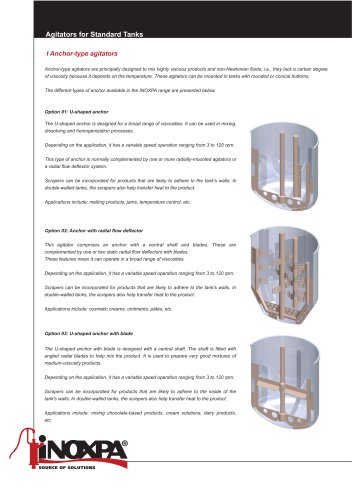

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages