Website:

INOXPA

Website:

INOXPA

Catalog excerpts

I Application The DCH is a twin screw pump, with hygienic design, suitable for use in the food, dairy, beverage and cosmetic industries. The flow is uniform and in an axial direction, so there are no changes of volume or physical properties of the product. Therefore, it is an ideal pump for handling shear-sensitive fluids. It has a high suction lift capability with very low NPSH values. It is capable of pumping liquids with high viscosity, but also with low viscosity, so it can be used as a CIP-supply pump. The design ensures a fully cleanability and drainability. The DCH pumps are available in two versions: close coupled and bare shaft construction. Having a three part design (suction casing, discharge casing and separate flange) to dismantle the pieces more easily, and designed according to the EHEDG recommendations. The mechanical seals have a hygienic design and when required, other materials can be used. I Technical specifications Materials: Parts in contact with the product AISI 316L Bearing support AISI 316 Gear Housing Aluminium Gaskets in contact with the product EPDM Mechanical seal: Rotary part Stationary part Gasket Silicon carbide (SiC) Silicon carbide (SiC) EPDM Surface finish: External Matt Operating limits: Maximum flow Maximum differential pressure Maximum working pressure Temperature range Temperature SIP, max. 30 min Maximum speed

Open the catalog to page 1

I Technical specifications Max. flow Triphasic induction motor with B5 flange and B3 legs, in compliance with the IEC standards, Efficiency class according to EC regulation, IP 55 protection and F-class insulation. Mechanical seals: TuC/TuC. Knife-edge single mechanical seals. Double mechanical seals. Gaskets: FPM, HNBR, FFKM. Heating chamber. Bareshaft version. Different types of connections. ATEX certification.

Open the catalog to page 2

Type Motor IEC DN1 DN2 ABCDEFGH I JK L M kc

Open the catalog to page 3All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

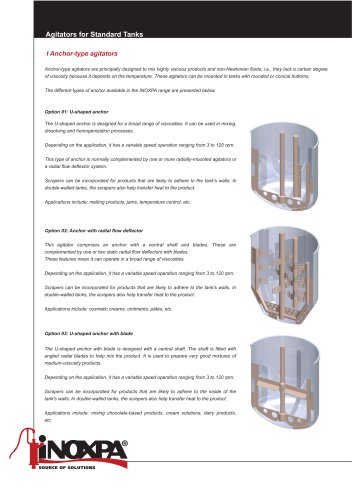

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages