Website:

INOXPA

Website:

INOXPA

Catalog excerpts

Hygienic DIN Centrifugal Pump I Applications The DIN-FOOD pump is a hygienic high capacity centrifugal pump (up to 1000 m³/h) designed to cater for an unfulfilled need in the food-processing and chemical and pharmaceutical industries. Its applications include processes in the brewing, dairy and beverage industries in general, as well as in ultra-filtering processes. It can also be used in the textile industry and in some specific processes in the chemical, cosmetics and pharmaceutical industries. I Operating principles Housed inside the casing, the impeller rotates in conjunction with the pump shaft. With this arrangement, the impeller blades convey energy to the fluid in the form of kinetic energy and pressure energy. This pump is not reversible by a simple reversal of the direction of rotation. The direction of rotation is clockwise when the pump is viewed from the rear side of the motor. Casing with volute manufactured with 8 mm cold-formed plate. Aseptic flanges according to DIN 11864-2. Double curvature impeller with blades on the rear side to reduce the axial thrust. Axial adjustment of the impeller (bare shaft version). Hygienic mechanical seal. Fully drainable pump. Designed according to the EHEDG standards. IEC B3 motors (B35 close-coupled constructions), IP 55, F-class insulation. I Materials Parts in contact with pumped media Lantern and bearing support Gaskets Mechanical seal Inside surface finish Outside surface finish Hygienic mechanical seal AISI 316L CF8 / GG-22 EPDM according to FDA 177.2600 SiC/C/EPDM Ra ≤ 0.8 Satin finish I Options Close-coupled construction for models 250. Mechanical seal in SiC/SiC for abrasive materials. Tandem type mechanical seal and pressurized double mehcanical seal. Gaskets: FPM and PTFE. Industrial finish (DIN-TEX). Motor shroud. Motors with additional protection. Stainless steel base plate. ATEX version available.

Open the catalog to page 1

I Technical specifications Max.flow Max.differential head Max.operating pressure Max.working temperature I General dimensions Pump DNa DNi d l a f h1 h2 b m1 m 2 n1 n2 n3 s1 s3 w The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

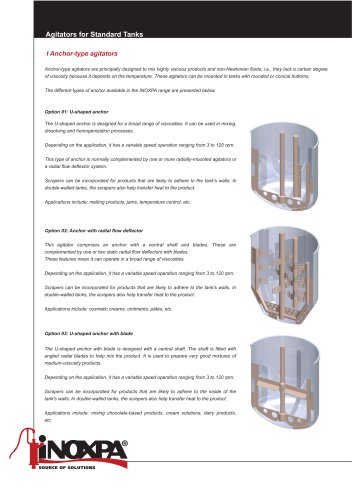

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages