Website:

INOXPA

Website:

INOXPA

Catalog excerpts

FTph.Ferm_EN - 2024/09 page. 1/2 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com Fermentation systems A P P L I C AT I O N The microbial fermentation is the most applied method in biotechnology, and nowadays it is distinguished by innumerable applications. An example of this is the industrial scale production of erythromycin, antibiotic obtained from Saccharopolyspora erythraea under aerobic conditions. Vitamins like riboflavin, beta carotene and vitamin B12 is also produced industrially by microbial fermentation. P R I N C I P L E O F O P E R AT I O N The typical batch mode fermentation is presented by the following stages: addition of a solution rich in nutrients, inoculation of microorganisms, injection of foam inhibitor and oxygen ( many microorganisms used in bioprocessing are aerobic). In his type of fermentation systems, the accumulation of waste products and multiplication of the microorganisms provokes the variation of conditions during the fermentation process. Vitamins, minerals, fatty amino acids and, depending on the bacteria type, growth factors can be added throughout the fermentation cycle. The foam inhibitor is added to control the excess of bubbles, the agitation system facilitates the dissolution of oxygen and release of carbon dioxide and provides a total mixing of nutrients. The process is efficient if the fermentation cycle is carried out at a constant temperature. The chemical reactions and the mechanical processes, occurring inside the fermentation vessel, heat the system and if the heat is not balanced, the cells may die or stop reproducing. Therefore, the cooling process requires an appropriate control system. The pH and oxygen levels, temperature, agitation, etc. of a fermentation process are automatically controlled by a PLC. The most frequent problems occurred during the fermentation process is contamination due to an inadequate sterilization or loss of sterility during the process. The use of reliable and high-performance systems provide safety conditions for high quality production.

Open the catalog to page 1

page. 2/2 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com Single (dry running) Sterile DESIGN AND FEATURES INOXPA offers various types of fermenters for a wide range of applications. The features of the fermentation / bioprocessing solutions are: • Design conforms to ASME BPE. • Skid-mounted structure. • Tank jacketed and insulated. • CIP/SIP design. • The control system is totally automated, the PLC controls and records all...

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

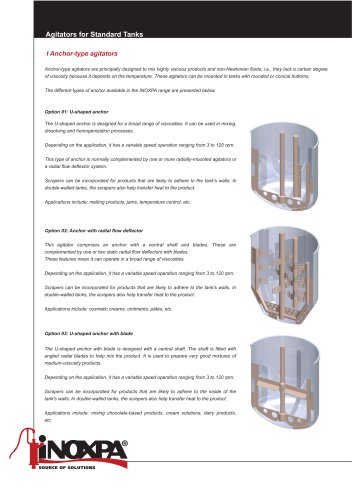

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages