Website:

INOXPA

Website:

INOXPA

Catalog excerpts

Hygienic Lobe Rotor Pump I Application The HLR pump is a lobe rotor pump designed in compliance with the EHEDG specifications for plants and processes that comply with the strictest hygienic requirements. Due to the low working speed, the pump is characterised by a gentle pumping and low shear of the product causing less damage possible. It is an ideal pump for the transfer of all types of liquids (from 1 to 1.000.000 cP) and liquids with solid particles (curd, biologic cultivations, etc.). The pump is adequate for the food-processing, cosmetic and pharmaceutical industries. I Operating principle The HLR pump basically consists of two lobe rotors which rotate inside the casing without touching each other. As the rotors rotate, the space between the lobes and the casing is successively filled with the product which is driven to the discharge nozzle displacing a fixed amount of product. The pumped product forms a continous stream due to the adjusted tolerances of the lobes and the pump casing thus ensuring an efficient pumping. I Design and features Vertical support. Bare-shaft construction. Self-drainable pump. Tri-lobe rotors. Hygienic design of the attachment of the lobes. Sanitary mechanical seal, internal assembly. The seal is disassembled from the frontal part without disassembling the casing of the pump. Gaskets with deformation limiters prevent any dead leg. Easy cleaning and maintenance. Standard connection: clamp. I Materials Investment casting casing and lobes ball bearing support Gaskets Mechanisal seal Internal surface finish External surface finish AISI 316L GG-25 EPDM according to FDA 177.2600 SiC/C/EPDM Ra ≤ 0,8μm bright polish

Open the catalog to page 1

I Options Mechanical seal: SiC/SiC, TuC/SiC. Flushed or balanced mechanical seal. Bi-wing lobes. Relief valve or external by-pass. Heating jacket. Ra < 0,5 ym surface finish for pharmaceutical applications. Horizontal assembly (no EHEDG certificate). Various types of drives and protections (gear motor with frequency converter, etc.). Assembly on a 304 stainless steel baseplate on silent-blocks, sanitary design. Trolley and control panel. Material certificates (3.1), roughness certificate. The pump can be ATEX certified. Max.differential head Max.working pressure Max.working temperature...

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

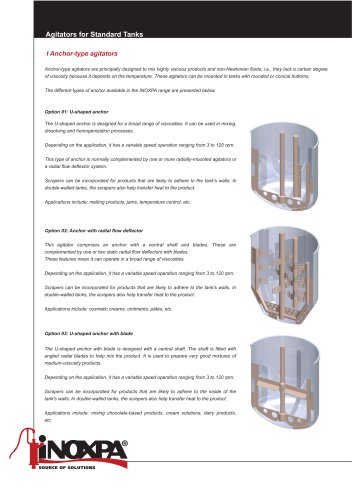

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages