Website:

INOXPA

Website:

INOXPA

Catalog excerpts

Progressive Cavity Pump I Application Kiber KS progressive cavity pumps are used to transfer products of low and high viscosity as well as products containing soft particles. They are also recommended for use with edible oils, wine, concentrates and beverages in general. They can also be used to transfer viscous food products. I Design and features KS type is a sanitary progressive cavity pump. Bare shaft construction with bearing support. Due to the design, they are self-priming and reversible. Open transmission (hygienic design). Excentric outlet. I Technical specifications Materials: Parts in contact with the product Other steel parts Bearing support Stator Gaskets in contact with the product Stainless steel AISI 316L (1.4404) Stainless steel AISI 304 (1.4301) GG-22 NBR negro (according to FDA and EC 1935/2004) FPM (according to FDA and EC 1935/2004) Single internal mechanical seal EN 12756 l1k (according to FDA and EC 1935/2004): Rotary part Silicon carbide (SiC) Stationary part Carbon (C) Gaskets FPM Surface finish: Internal External Connections: Bright polish, Ra ≤ 0,8 μm Matt DIN 11851 CLAMP SMS Operating limits (depending on the model): Maximum flow 45 m³/h 198 US GPM Maximum working pressure - single stage 6 bar 87 PSI - double stage 12 bar 174 PSI Maximum working temperature 85 ºC (depending on materials) 185 ºF Maximun speed 1450

Open the catalog to page 1

I Technical specifications Type Double pressurized mechanical seal. Single flushed mechanical seal (Quench). Mechanical seal: SiC/SiC. Gland packing. Stators: white EPDM and black NBR. Gaskets: EPDM. Other types of connections. Heavy-duty transmission. Fixed transmission. Pump casing with heating jacket. Stainless steel trolley. Electrical control panel. Bypass pressure relief valve. ATEX certification. The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our...

Open the catalog to page 2

The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Open the catalog to page 3

Progressive Cavity Pump The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Open the catalog to page 4All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

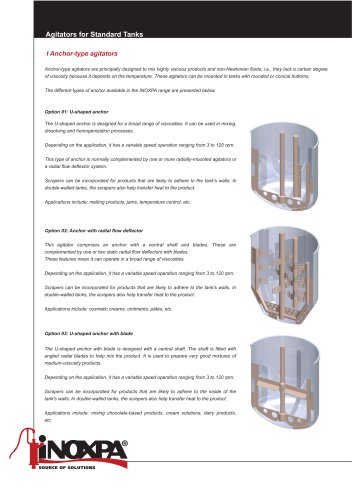

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages