Website:

INOXPA

Website:

INOXPA

Catalog excerpts

FTsolMBC_EN - 2024/07 page. 1/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com MBC Double Cone Solids Blender A P P L I C AT I O N The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as food, cosmetics, pharmaceutical, chemical, detergents, fertilizers and plastics. Examples of materials or substances mixed in this way include pharmaceutical granules, semolina flour, seeds, starch, coffee beans and ground coffee, cocoa, chocolate flakes or granules, powdered milk, baby food, preparations to make dehydrated soups and creams, leaf waxes, detergent granules, soap flakes, artificial fertilizers, plastic in powder, ground or pellet form, fibreglass, etc. P R I N C I P L E O F O P E R AT I O N The main body of the blender consists of two cone-shaped sections welded at their bases to a central cylindrical section. The axis of rotation is perpendicular to the cone axis and passes through the cylindrical section. The driving motor is located at one of the two lateral supports holding the blender body. The solids are introduced into the blender through the loading aperture. In this type of blender, mixing takes place axially, as a result of the powder moving through the different sections. Mixing is thorough but it depends on the rotating speed. The mixture is discharged through a hermetically closing butterfly valve which can be operated manually or automatically. The skid has an electrically secured safety perimeter guard to prevent operators from gaining access during use. In the event of accidental access, for safety reasons the process will be stopped. D E S I G N A N D F E AT U R E S The series consists of 6 models with a total capacity of 160 to 4200 litres and a useful capacity of 65% of the total. This blender is especially designed for sensitive mixtures with risk of breakage where the generation of dusts is to be avoided. Mixing times vary between 5 and 20 minutes depending on the mixture. There are two apertures: the loading and cleaning aperture, and the discharge opening, which incorporates a butterfly valve thatcan be operated automatically or manually. The apertures are sealed hermetically in order to avoid contamination from the outside during the mixing process. The interior of the blender incorporates a cone mounted on the pivot axis on both sides. This system eliminates the formation of dead spaces and facilitates gravity discharge.

Open the catalog to page 1

D E S I G N A N D F E AT U R E S The skid is manufactured in AISI 316 (EN 14404) for all parts in contact with the product and AISI 304 (EN14301) for the rest of the equipment. Standard finish is Ra<0.8 on the inside and 2B on the outside. Easy to clean, both manually and with an automatic CIP system, thanks to its hygienic design and the absence of entrapment areas. It has perimeter safety protection with a door, is manufactured in accordance to EC safety standards. DETALHE / DETALLE J ESCALA: / ESCALA: (1 : 10) The automatic stop positions are: loading, unloading and sampling. Before...

Open the catalog to page 2

OPTIONS Motors, instrumentation and valves are available in accordance to ATEX protection, as an option. Interior and exterior mirror polishing also optional. The unit can be equipped with an automated loading system for introducing powders and granules into the blender body by means of a vacuum unit with self-cleaning hoses. It prevents creation of dust. The loading and unloading systems can be automated on request with a butterfly valve with pneumatic dosing system. The skid can also be provided with a complete monoblock vacuum unit with liquid ring pump. It may include an automatic...

Open the catalog to page 3

GENERAL DIMENSIONS page. 4/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com Total Useful Model Volume Volume A B C 0D E F H I (litres) (litres) * Geared motor OPTIONS Vacuum loading system Vacuum discharge system

Open the catalog to page 4All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

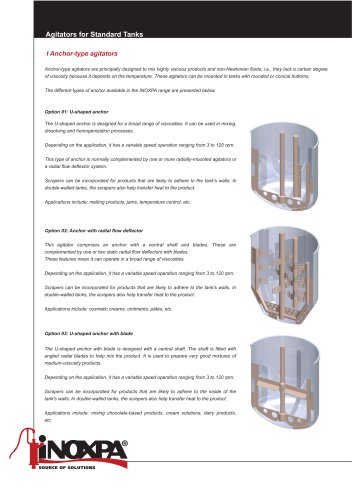

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages