Website:

INOXPA

Website:

INOXPA

Catalog excerpts

FT 20.072.33.01EN (0) 2022/05 pàg. 1/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com O P E R AT I N G P R I N C I P L E The agitator consists of two coaxial shafts connected to two geared motors that rotate in opposite directions. The central shaft rotates at higher speeds and has propellers optimized for dispersion and mixing in low-viscosity phases. The outer shaft is connected to an anchor with scrapers to homogenize and remove the product from the tank walls, preventing it from overheating and allowing faster and more homogeneous heat transfer. Additionally, it behaves as a deflector for the central propellers when the product has low viscosity. It can be configured with a wide range of powers and turning speeds, giving the mixer great application versatility. A P P L I C AT I O N S Hygienic design suitable for pharmaceutical, cosmetic and food products. Indicated for complex and fluid agitation processes with extreme behaviours. Mixing and homogenization of medium and high viscosity products. Optimal for products with changes in viscosity throughout the process. Additionally, using a variable frequency drive, the speed of rotation can be modified in the different stages. The scraper anchor helps to homogenize the temperature in processes with heat transfer. Very suitable for heat exchange processes. D E S I G N A N D F E AT U R E S Hygienic design according to EHEDG guidelines. Optimized for CIP and SIP processes of all internal components. Easy maintenance and replacement of wear parts such as mechanical seal and bearing. Independent high-efficiency bevel gear motors for anchor and central shaft. The mixing elements are adapted to the requirements of the equipment geometry and process parameters. CONFIGURABLE ELEMENTS The agitator has a modular design and is fully configurable with different options for surface finish, sealing system and elastomeric materials, type of anchor, different lower anchor support systems and, in addition, the possibility of ATEX certification.

Open the catalog to page 1

pàg. 2/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com Surface finish Standard surface finish is Ra ≤ 0,8μm. Also available with Ra ≤ 0,4μm surface finish for pharmaceutical applications. Explosive atmospheres ATEX certificate option for work in explosive atmospheres using certified gearmotors and mechanical seals as well as scrapers made of antistatic material. Gearmotor Geared motor with H1 food grade oil and in RAL9016 white...

Open the catalog to page 2

TECHNICAL SPECIFICATIONS Materials Components in contact with product Other steel components Mechanical seal Mechanical seal elastomers Lip seal Operating limits Working pressure -1 to 6 bar MCR-1 MCR-2 MCR-3 MCR-4 MCR-5 MCR-6 MCR-7 MCR-8 pag. 3/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com RECOMMENDED CONFIGURATIONS The following table presents recommended agitator configuration for products with a viscosity of less than...

Open the catalog to page 3

pag. 4/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com

Open the catalog to page 4All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

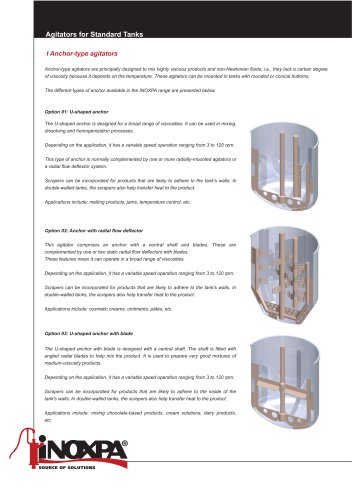

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages