Website:

INOXPA

Website:

INOXPA

Catalog excerpts

Inline Mixer I Application The ME-4100 series of the inline high shear mixers offers a possibility to pump, disperse, homogenize and emulsify products with one and the same equipment. Numerous chemical, food-processing, pharmaceutical and cosmetics production processes require this system due to the lack of space inside the tanks for vertical or tank bottom mixers. These mixers are especially useful in already existing plants. They can work with a recirculation tank reaching the best efficiency after several passes of the product through the mixer. I Operating principle The casing is similar to a casing of a centrifugal pump, it houses the stator and the rotor. It is characterised by a high shear due to an adjusted tolerance between the rotor and the stator and the high speed of the rotor. The product is suctioned through the inlet and the rotor pushes it to the stator. Passing through the slots of the stator the product is mechanically sheared, the particles are sheared by the rotor at the speed of more than 20 m/s. And finally the flow is hydraulically sheared leaving the stator through the slots at a high speed. If the viscosity of the product is higher than 200cP, it is recommended to put an auxiliary pump at the inlet of the mixer, and if a high discharge pressure is required, it is necessary to assemble another auxiliary pump. I Design and features High shear, particle size reduction to less than 100 microns. Sanitary single mechanical seal. Slotted head (standard). Various easily interchangeable working heads. Completely CIPable design. Drain port connection (in the casing): clamp DN-3/4". Standard connections: Clamp ISO-2852. Close-coupled construction, small baseplate. Motor shroud. Motors: IEC B35, IP 55, F-class insulation. I Materials Parts in contact with the product Other stainless steel parts Mechanical seal Gaskets Surface finish AISI 316L AISI 304 C / SiC / EPDM EPDM Ra ≤ 0.8μm

Open the catalog to page 1

I Options Disintegrating head. Fine screen head. Cooled or pressurised mechanical seal. Baseplate with antivibration legs. Trolley with/without control panel. Mirror polish Ra < 0.5 pm for the pharmaceutical applications. Other motor protections. ME-4130 model: option of a bare shaft contsruction. * Selection data for the products with the viscosity below 50cP. Approximate values. The selection can vary depending on the application. Dimensions with CLAMP connections. For bigger sizes consult Inoxpa Solutions.

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

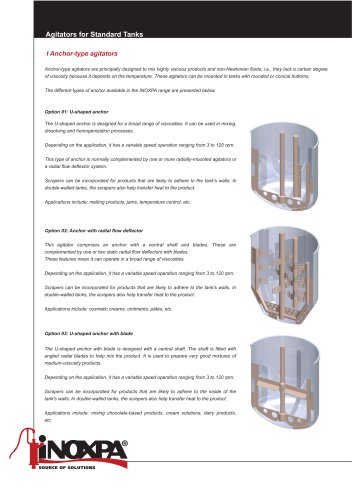

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages