Website:

INOXPA

Website:

INOXPA

Catalog excerpts

FT 03.600.33.01EN · (0) 2024/04 pàg. 1/3 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. ME-6100 Tank Bottom Mixer A P P L I C AT I O N The ME-6100 series of the high shear bottom of the tank mixers present a highly hygienic solution for the processes of dispersion, emulsifying, homogenisation and disintegration of solids in the food-processing, cosmetics, pharmaceutical and fine chemistry industries. These mixers can be used either in open or closed tanks at atmospheric pressure or under pressure/vacuum. The bottom of the tank mixers are designed for the applications of the highly viscous media and intended for work with anchor type agitators. O P E R AT I N G P R I N C I P L E The high speed and adjusted tolerances between the rotor and the stator result in high suction potential, the product is suctioned and driven to the centre of the head. The product is suctioned from the upper part of the head and the rotor thrusts it radially. Passing through the opening of the stator the product is mechanically sheared, the particles are sheared by the rotor at high speeds. And finally this flow is hydraulically sheared leaving the stator through the slots at a high speed. D E S I G N A N D F E AT U R E S High shear, particle size reduction to less than 100 microns. Access to the mechanical seal from the inside of the tank. Single sanitary mechanical seal. Possibility to replace the stator without disassembling the mixer. The circulation is promoted as the stator is geometrically higher than the rotor. Different model of stators are easily interchangeable. Motors: IEC B5, IP 55, F-class insulation. Easy cleaning and sterilisation (CIP/SIP). Slotted head. T E C H N I C A L S P E C I F I C AT I O N S Materials Parts in contact with the product Other steel parts

Open the catalog to page 1

Gaskets in contact with the product Mechanical seal Surface finish OPTIONS Double mechanical seal. Flushed mechanical seal. Disintegrating stator. Fine screen stator. Bare shaft construction for big size models and transmission by pulleys and belts. Ra < 0.4 pm surface finish for pharmaceutical applications. Other motor protections. pag. 2/3 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. DIMENSIONS Tank flange

Open the catalog to page 2

QUICK SELECTION TABLE Approximate selection table. The selection can vary according to the application. Motor Tank Volume [L] Model Power Speed pag. 3/3 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com.

Open the catalog to page 3All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-4100

2 Pages

-

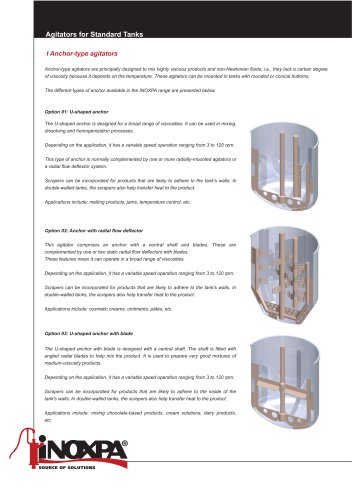

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages