Website:

INOXPA

Website:

INOXPA

Catalog excerpts

Digital catalogue: Interactive table of contents Interactive action symbols External links FOR THE PHARMACEUTICAL AND COSMETIC INDUSTRY INOXPA FOR THE PHARMACEUTICAL INDUSTRY INOXPA FOR THE COSMETIC INDUSTRY INOXPA FOR THE HOUSEHOLD PRODUCTS AND FINE CHEMICALS INDUSTRY SOLUTIONS AND SYSTEMS LIQUID / SOLID PROCESSES AUTOMATION ATEX VALIDATIONS COMPONENTS CASE STUDIES PILOT PLANT DISTRIBUTION NETWORK

Open the catalog to page 2

RELIABILITY, SAFETY AND OPTIMISATION OF PROCESSES Our knowledge and know-how accumulated over the years means we can offer tailored solutions and manufacture products based on each company’s needs. TECHNICAL KNOWLEDGE AND COMPONENTS FOR QUALITY SOLUTIONS EXPERTS IN SOLUTIONS FOR THE PHARMACEUTICAL AND COSMETIC INDUSTRY In order to ensure the best possible outcome for our solutions, we have an extensive range of proprietary manufactured components and apply process knowledge to the design of all equipment and installations, as such complying with Good Manufacturing Practices (GMP) that...

Open the catalog to page 3

INOXPA FOR THE PHARMACEUTICAL INDUSTRY INOXPA FOR THE COSMETIC INDUSTRY The pharmaceutical, biotechnology and veterinary sectors are undoubtedly the most demanding in terms of hygiene. The cosmetic industry is constantly evolving, with hygiene requirements and health demands becoming more stringent, in some cases requiring installations and equipment with pharmaceutical level finishes and certifications. Equipment and installations must be rigorously designed in accordance with the strictest standards and use high quality components that comply with the most stringent health and safety...

Open the catalog to page 4

INOXPA FOR THE HOUSEHOLD PRODUCTS AND FINE CHEMICALS INDUSTRY These sectors are evolving from a chemical and industrial concept towards requiring significant hygiene levels, similar to those in the cosmetic and pharmaceutical industries. Storage, transportation and dosing of solid ingredients INOXPA can bring their experience and knowledge in these areas to support companies through such a demanding yet necessary transition. Product recovery system. PIG CIP / SIP units Automation Installation and start-up IQ/OQ qualifications Flow transfer and handling In-line mixing Storage equipment...

Open the catalog to page 5

LIQUID / SOLID PROCESSES INOXPA have accumulated over 50 years’ experience in liquid product pumping, blending and flow management, and after a specialised company was recently added to the group, we also have vast knowledge of storage, transportation, mixing and dosing of solids. This means we can undertake global projects, applying the technological requirements for both areas. AUTOMATION Our equipment, installations and plants always come with high level of automation so they can be validated, including a system of recipes, reports or records, the possibility of SCADA supervision...

Open the catalog to page 6

ATEX Many processes in the pharmaceutical and cosmetic industry use products that can generate an explosive atmosphere due to the use of inflammable liquids, alcohol, acetone or other solvents (zone 1 / 2), or due to dust clouds (zone 21 / 22). INOXPA have knowledge and experience in designing and manufacturing category 2 and 3 equipment in order to be able to work in these zones and to perform tests and generate necessary documentation and dossiers, which are submitted to the notified body when required, in accordance with directive ATEX 2014/34/EU. VALIDATIONS INOXPA have the capacity and...

Open the catalog to page 7

Standard Number 02-12 Standard Number 02-11 Progressive cavity pump: Kiber Rotary lobe pump: SLR Centrifugal pumps: Prolac HCP, Prolac HCP-WFI Tank bottom mixer: ME 6100 Agitator with mechanical seal: CXC Seat valves Product recovery system: PIG

Open the catalog to page 8

PILOT PLANT CASE STUDIES From its very first moment, INOXPA has had but one objective: to satisfy the needs of its customers. To achieve this goal, INOXPA is committed to bringing a quality service closer to the customers. We have a fully equipped Pilot Plant in which we can perform any type of test and reproduce recipes on a small scale to validate your manufacturing process using INOXPA equipment. The results enable our technical team to advise our customers regarding optimisations for their manufacturing processes.

Open the catalog to page 9

DISTRIBUTION NETWORK Our extensive network of branches and distributor partners ensures we are close to our customers to guarantee them a fast and effective service from project development through to implementation and validation, including after-sales phase, and throughout the installation’s useful life.

Open the catalog to page 10All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

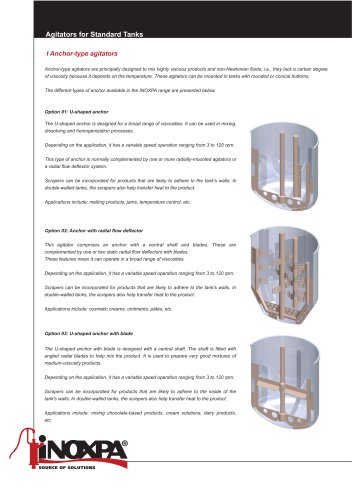

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP WFI

2 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages