Website:

INOXPA

Website:

INOXPA

Catalog excerpts

FT 01.030.33.02EN (0) 2022/05 pàg. 1/2 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com PROLAC HCP WFI Centrifugal Pump A P P L I C AT I O N Higher standards are required in the pharmaceutical industry than in the food industry to pumping products like purified water (PW), water for injection (WFI), etc. D E S I G N A N D F E AT U R E S Using the HCP centrifugal pumps as a base, we have designed the HCP-WFI model, which adds the most popular options in pharmaceutical applications to the PROLAC HCP pump. HCP pumps are sanitary grade centrifugal pumps designed in accordance with EHEDG recommendations. The HCP can easily be cleaned by using chemical products (CIP) and suitable for steam sterilisation (SIP). Supplements to the basic configuration of a PROLAC HCP pump: - The discharge port orientated to 45º to evacuate air bubbles that could remain in the upper part of the pump housing. - Surface finish of the parts in contact with the product: Ra<0.5 μm. - Simple mechanical seal: TuC/SiC. - FDA and USP Class VI certified EPDM O-rings. - ½” CLAMP drain port in the pump housing. - CLAMP OD connections. - Materials certificate 3.1 (according to EN10204). - Gasket certificate 2.1 (according to EN10204). - Roughness certificate. Sanitary grade mechanical seal, according to EHEDG standards, with hard faces avoids the possibility of dust traces contaminating the product being pumped. AVA I L A B L E O P T I O N S Vertical discharge port (0º). Double seal and cooling circuit with the liquid being pumped, with the possibility of adding different accessories (pipework, check valve, diaphragm valve, etc.). Drainage valve with various possible configurations (manual or automatic diaphragm valve, stainless steel or plastic bonnet etc.). Hydraulic test certificate with guarantee. Electro-polished finish

Open the catalog to page 1

Cooling circuit Single mechanical seal pag. 2/2 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com Drainage valve

Open the catalog to page 2All INOXPA catalogs and technical brochures

-

C-TOP S

4 Pages

-

Manifold

3 Pages

-

INNOVA N

3 Pages

-

INNOVA K

4 Pages

-

STERIPIG

2 Pages

-

CIP

3 Pages

-

M-226

4 Pages

-

MM

3 Pages

-

8100X

2 Pages

-

ME-6100

3 Pages

-

ME-4100

2 Pages

-

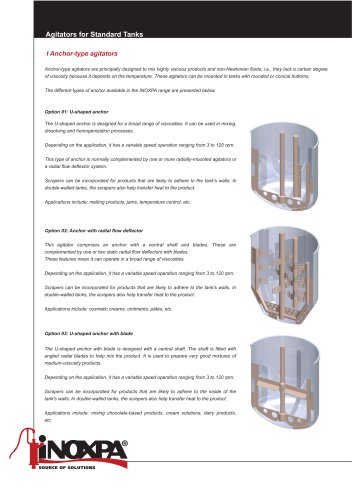

Agitators for Standard Tanks

6 Pages

-

NBI

2 Pages

-

81700 / 82700 / 83700

4 Pages

-

7550

2 Pages

-

72700

2 Pages

-

A470

4 Pages

-

A480 / A490

5 Pages

-

74700

3 Pages

-

INNOVA Mini K

4 Pages

-

INNOVA Mini N

3 Pages

-

MV

5 Pages

-

MBC

4 Pages

-

CMC-ATEX

3 Pages

-

Fermentation systems

2 Pages

-

MCR

14 Pages

-

CXC

2 Pages

-

NHS

2 Pages

-

DINAMIX SMX

5 Pages

-

BMA

2 Pages

-

MCR

4 Pages

-

Kiber KS

4 Pages

-

DCS

3 Pages

-

DCH+

3 Pages

-

DCH

3 Pages

-

TLS

3 Pages

-

SLRT

2 Pages

-

HLR

2 Pages

-

SLR

4 Pages

-

ASPIR

5 Pages

-

RVN

3 Pages

-

RV

2 Pages

-

Estampinox EFI

4 Pages

-

Hyginox SEN

3 Pages

-

HYGINOX SE

5 Pages

-

Prolac HCP SP

4 Pages

-

PROLAC HCP

5 Pages

-

DIN-FOOD

2 Pages

-

Angular filter

17 Pages

-

BUTTERFLY AND BALL VALVES

4 Pages

-

INNOVA SEAT VALVES

36 Pages

-

FOOD INDUSTRY

10 Pages

-

PHARMACY AND COSMETICS

10 Pages